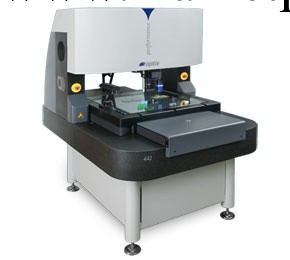

海克斯康Optiv Performance 影像儀

采用穩固的機構,提供瞭完整的傳感器選擇,Optiv Performance系列光學影像測量系統提供瞭完成各種測量任務的優化選擇。

概述

采用穩固的機構,提供瞭完整的傳感器選擇,Optiv Performance系列光學影像測量系統提供瞭完成各種測量任務的優化選擇。 Optiv Performance提供瞭五種尺寸系列,測量范圍包括:250 x 200 x 200 mm,410 x 410 x 200 mm,610 x 610 x 200 mm,600 x 600 x 400 mm,920 x 800 x 200 mm。

Optiv Performance主要完成各種高精度的測量任務,並包括更加復雜的測量任務。

Optiv Performance 222設計特點

機械軸承

臺面式設計,十字工作臺移動

多傳感器技術

1Z

測量范圍:250 x 200 x 200 mm

I. 技術描述Technical Description

A. 主要特征Key Features

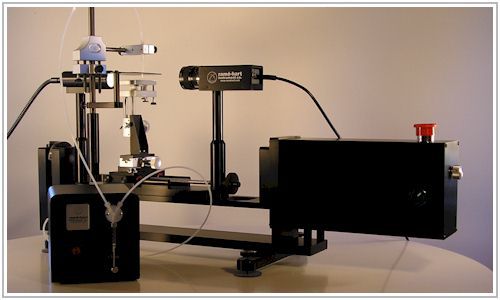

精密緊湊的3D測量機.花崗巖基座,高精度線性導軌,輕質高強度特種鋁合金框架,玻璃工作臺.計算機控制的照明光源系統:同軸光(頂光),背光(投射光)及4段環形照明光.專利的USP設計技術,集多種傳感器於一體,直流伺服電機,滾珠絲桿傳動,真正的3維補償。

a) 花崗巖基座—性變小,穩定性好,壽命長。

b) 導軌—NSK特制直線導軌,從導軌的寬度和厚度均比普通導軌尺寸大、精度高。

c) 驅動設計—三軸采用中央軸承驅動方式,移動均衡、平穩。

d) 傳動—NSK滾珠絲杠。

e) 電機—德國馮哈伯Faulhaber或瑞士Maxon,均為世界上著名的微型電機制造商。

f) CCD—Sony 43萬像素黑白CCD相機。

g) 光柵尺— 海德漢高精度光柵。

Compact type 3D-CMM. Machine base is made of rigid granite. Allaxes guided by high precision linear guideways. Measuring table ismade of special aluminium featuring low weight and high rigidity.coperated with computer fiber optic lightsources for coaxial (top) and back light illumination. Also,enhanced with computer controlled 4-quadrant LED ring light.Universal Sensor Platform (USP),Ball Screw,3D space compensation, High-precision DC servo motor.

B. 技術指標 PerformanceSpecifications

光學 μm | E1x ,E1y=1.4+L/200 | L單位為mm 光學測量精度依據VDI/VDE 2617-6標準或ISO10360-7; E3:配備接觸測頭3維空間精度,依據ISO10360-2 |

E1z=1.9+L/200 | ||

E2xy=1.5+L/150 |

l 空間運行速度:250 mm/s

l 光柵尺分辨率:0.1um海德漢金屬光柵

l 測量范圍: 250 X 200 X 200mm (X/Y/Z)

l 高分辨率工業級CCD相機:752 x 582像素

l 驅動系統:精密直流伺服電機驅動、滾珠絲桿

l 工作臺承重: 10公斤

l 機器毛重: 260公斤

l 隨機附帶:檢測報告;合格證;用戶手冊

Vision μm | E1x ,E1y=1.4+L/200 | L in mm Vision accuracy according to VDI/VDE 2617-6 or ISO 10360-7 E3:Only with option with touch probe according to ISO10360-2 |

E1z=1.9+L/200 | ||

E2xy=1.5+L/150 |

l 3D travel speed:250 mm/s

l Measuring System:HeidenhainLinear incremental 0.1 um resolution scales.

l Measuring span: 250 X 200 X 200mm (X/Y/Z)

l High-resolution CCD camera:752 x 582 pixels

l Drive System:DC-servo drives with precision, backlash free ball screwsmounted in the center of mass

l Max. Load capacity: 10kg

l Mass: 260kg

l The machine comes fully assembled with:

- Inspection Report

- Declaration of conformity

- Instrument manual

C. 放大倍率參數 Magnification information

鏡頭 Lens | 工作距離 Working distance | 像素尺寸 Pixel size (μm) | 視場大小 FOV HxV (mm) | 放大倍率/17寸顯示器 Magnification on 17” |

1x | 79mm | 6.35 / 21.09 | 4.8x3.7 / 15.9x12.3 | 70x / 20x |

3x | 75mm | 2.12 / 7.03 | 1.6x1.2 / 5.3x4.1 | 210x / 60x |

5x | 64mm | 1.27 / 4.22 | 1.0x0.7 / 3.2x2.5 | 350x / 100x |

10x | 48mm | 0.64 / 2.11 | 0.5x0.4 / 1.6x1.2 | 700x / 200x |

20x | 20mm | 0.32 / 1.05 | 0.2x0.2 / 0.8x0.6 | 1400x / 400x |

D. 設備外形尺寸Machine Size

E. 計算機系統ComputerSystem

l 英特爾雙核處理器2x2,4 GHz l 正版微軟Windows XP或Windows7多語言操作系統 l DVD刻錄 l 256MB VGA顯卡 l 2G內存 l PS/2鼠標和鍵盤接口 l 17英寸顯示器 l 1200mm電腦桌,可放置顯示器、鍵盤、鼠標、操作盒 | l PC Intel Core 2 with 2x2,4 GHz Chipset l Microsoft Windows XP orWindows7Professional Multilingual l DVD-writer l VGA card with 256 MB DDR RAM l 2x 1024 MB RAM l PS/2- mouse and keyboard l 17“ TFT screen for Multisensor processing and measuring software l 1200 mmtable for Monitor, keyboard, mouse, Joystick |

F. 環境要求Required Specification

l 工作溫度:18℃~ 22℃(可保證精度)

l 相對濕度: 40%—70%RL l 工作電壓: 230V +10% l 頻率:50/60 Hz +5% l 功率:1000VA | l Working temperature range:18℃to 22℃(for guarantee accuracy) l Relative humidity: 40%—70%RL, noncondensing l Mains voltage : 230 V ± 10 % l Frequency: 50 Hz / 60 Hz ± 5 % l Consumption:1000 VA |

G. PC-Dmis CAD測量軟件/ Measuring Software System

PC-Dmis CAD測量軟件/ Measuring Software SystemPC-DMIS是海克斯康為廣泛的坐標測量用戶打造的高性價比測量軟件。作為全球計量行業標桿軟件,PC-DMIS融合瞭海克斯康在坐標計量行業內多年深厚的應用實踐經驗及對廣大用戶需求的精準把握。同時也緊跟信息科技發展步伐,兼容最新技術的32位、64位WINDOWS 7操作系統和形位公差標準。

PCDMIS CAD編程和比對測量,可以將數學模型(IGES、STEP、DFX/DWG等多種格式)直接導入,用於快速編程和實現實際測量數據與CAD的比對

PC-DMIS強大的掃描和逆向支持功能,提供瞭開放曲線、閉合曲線等多種路徑的掃描,測量數據可以多種常用CAD格式輸出,為復雜曲線曲面檢測和逆向工程提供瞭高效的解決方案。

PCDMIS是目前世界上應用最廣泛和功能最強的計量軟件,光學影像測量和接觸測量、激光測量可以使用在同一軟件實現影像、接觸、激光測量的完美統一,通過瞭世界上對於軟件算法最權威的德國PTB認證。

PC-DMIS is cost-effective measurement software for the vast numbers of users of Hexagon. As the benchmarking software of metrology industry in the world, PC-DMIS combines Hexagon coordinate measurement in the industry for many years practical experience in the application of deep and precise needs of the users to grasp. Meantime PC-DMIS also supports windows 7 based on 32 –bit and 64-bit operation system.

PCDMIS CAD programming and measurement, you can import the CAD module(IGES、STEP、DFX/DWG etc.) and using the CAD to program or compare the actual data with CADPC-DMIS powerful scanning and

reverse support functions to provide an open curve, closed curve such as the scanning path, measurement data can output a variety of commonly used CAD format for the complex curves and surfaces to detect and reverse engineering to provide an efficient solution.

| 點擊鼠標,即可完成各種測量功能,放大,旋轉和過濾功能。測量區域可以靈活調節環形大小和弧度大小。 Mouse control of the tool for field of view measurements, and tool sizing rotation filtering |

| 可從程序對光源進行控制以獲得最優的邊沿檢測效果 Automatic edge capture defaults for optimum edge collection |

| 真正的中文版軟件,包含界面、程序和幫助文件均為中文,並非簡單的界面的漢化 Really Chinese software, interface, program and help are all in Chinese, not only the translate of the user interface

|

| PTB認證 PTB certificate |

| 程序自動調用編程時的各種信息,光源類型和強度、測頭類型(光學、接觸),全自動移動和自動尋邊,自動對焦,自動剔除毛刺 PCDMIS will auto adjust all the program information, light type and density, probe type, auto moving and edge detector, auto focus, auto filter |

| 多特征捕獲功能,位於同一視場內的特征不論特征類型均可一次測量完成,測量效率提高3-5倍 Multi-Capture, PCDMIS can measure all the features in one field of view,3-5times speed than the normal measurement. |

| PCDMIS CAD編程和比對測量,可以將數學模型(IGES、STEP、DFX/DWG等多種格式)直接導入,用於快速編程和實現實際測量數據與CAD的比對 PCDMIS CAD programming and measurement, you can import the CAD module(IGES、STEP、DFX/DWG etc.) and using the CAD to program or compare the actual data with CAD |

| PCDMIS CAD用於逆向工程,可以將實物進行測量和掃描,將測量的實際數據以IGES、STEP、DFX/DWG等多種格式輸出,然後可通過UG、Pro-e等處理生成CAD模型進而生成加工程序。 PCDMIS CAD for reverse engineering ,the part can be measured or scanned, the measuring data can be exported to UG or Pro-e to create the CAD for process. |

| 圖形化分析,對於測量特征可以通過圖形和數據結合的方式分析缺陷的所在,圖示為圓度分析,可以明顯看到圓度存在問題的位置及偏差數據。 Graphical analysis,we can use this to see clearly the feature error position and data. For example the roundness analysis. |

| 采用ISO標準計算各種公差,形位公差包含直線度,圓度,平行度,垂直度,角度,對稱度,位置度,同心度等 ISO standard,Evaluations of geometrical element: Straightness, Roundness, Parallelism, Perpendicularity, Angularity, Symmetry, Position, Concentricity |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。