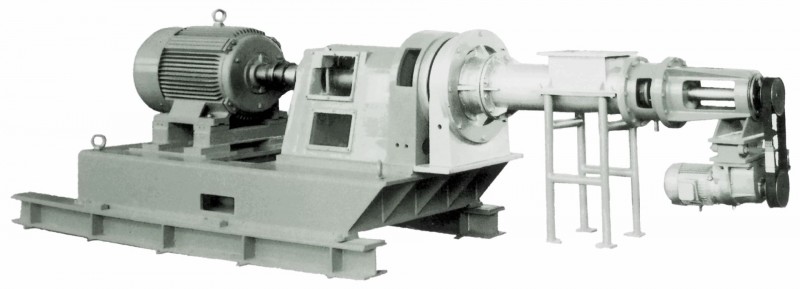

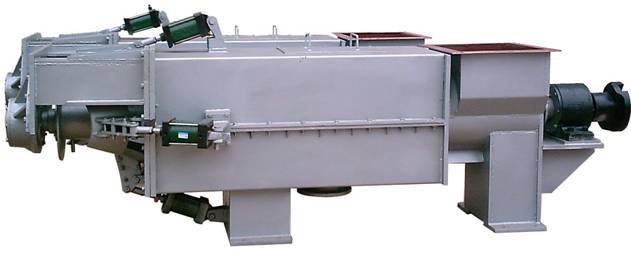

用於分散處理廢紙(OCC/ONP/OMG/MOW)中的膠粘物、油脂、石蠟、塑料、橡膠或油墨粒子等熱熔性雜質

動盤與靜盤間隙在一定范圍內可任意設定,可實現較小間隙狀態下的運行,更有利於剝離附著在纖維上的油墨,分散塵埃斑點、膠粘物和塗料離子。

動盤與靜盤齒形可改善纖維的工藝特性,有良好的潤脹效果,有利於漿料的漂白。

強製性喂料有利於漿料高效加熱和溫度的控製,減少長時間加熱而產生的負麵效應。

Application/ Features

This equipment applies to treatment of all kinds of pulp using waste paper as raw materials, being able to efficiently disperse all kinds of stickies and other impurities.

The clearance between dynamic disc and static disc can be set within a certain range , which can achieve running under smaller clearance and is more beneficial to separating ink adhering to fiber and dispersing dirt speckles, stickies and paint particles.

Tooth shape of dynamic disc and static disc can improve process characteristics of fiber , with good moistexpansion effect that is beneficial to bleaching of pulp.

Forced feeding is beneficial to efficient heading and temperature control of pulp. Therefore, reduce negative effect caused by long-time heading.

規格Specification

參數Parameters | LPS-22 | LPS -30 | LPS-37 | LPS-45 | LPS-55 | LPS-75 | LPS-90 | LPS-110 | LPS-132 | LPS-160 | LPS-200 | LPS -250 | LPS-315 |

生產能力Production capacity(T/D) | 10-15 | 15-20 | 20-30 | 25-35 | 30-40 | 40-60 | 45-70 | 50-85 | 65-100 | 80-120 | 100-150 | 120-190 | 140-210 |

磨漿濃度Pulping concentration(%) | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 |

主電機功率Main motor power(kw) | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 160 | 200 | 250 | 315 |

轉子轉速Rotor speed(rpm) | 2940 | 2950 | 2950 | 2970 | 2970 | 2970 | 2970 | 2980 | 2980 | 2980 | 1480 | 1480 | 1480 |

喂料螺旋直徑 Feeding screw dia.(㎜) | Ф130 | Ф130 | Ф140 | Ф155 | Ф155 | Ф150 | Ф165 | Ф175 | Ф175 | Ф175 | Ф200 | Ф200 | Ф225 |

喂料電機功率 Feeding motor power(KW) | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 | 5.5 | 5.5 | 7.5 |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。