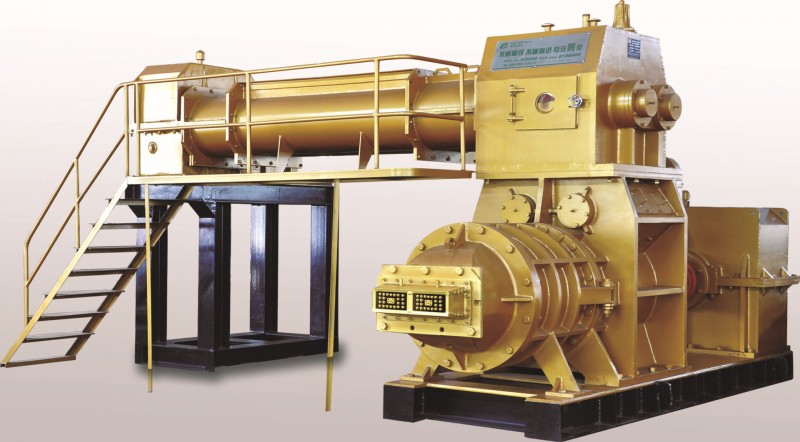

機器人碼坯主要由:運坯系統、存坯機系統、翻坯機系統、 編組系統、配電系統以及氣動系統等組成,運行平穩、定位 精準、操作方便、故障率低、效率高等特點。

運坯機工作原理:運坯機是由兩部分組成,當磚坯出現瑕疵時,第二部分的運坯機升起。 由第一部分的運坯機帶動直接把廢坯送入回坯道。

翻坯機工作原理:當存坯道的磚坯送到該設備上時,磚坯會在規定的時間內按規定的距 離到達翻坯機上,磚坯被翻坯機翻轉形成孔朝上.(雙泥條可上下疊加)再進入下道設備

存坯機工作原理:當運坯機把磚坯送到存坯機上達到設計要求的數量時存坯機會一次性把磚坯 送到下一設備上,該設備保證主機可連續生產。

編組系統工作原理:當磚坯經過翻坯機後直接送到編組機上編組托輥升起,會將磚坯分縫,保 證碼坯機夾板能順利夾磚。

It includes following systems: convey system, store system,turn system,marshalling system, power distribution system and pneumatic system. It is stable,accurate positioning,time-saving,low failure,high efficiency etc.

Principle of convey system: it contains two parts,when the green bricks have flaws,the secondparconvey system is uprising and the first part of convey system will send them back for recycling.

Principle of turn system: when the green bricks are sent to turn system from store system, green bricks will arrived turn systemin the setting time, the holes on green bricks are turned upalong,(Double clay bar can be stack up.)Then will be sent to next equipment.Principle of store system: when green bricks are sent to store system by convey system and the quantity of brick reaches the required data, store system will convey these green bricks to next equipment at a time,to ensure the main engine working continually.

Principle of marshalling system: when green bricks are sent to marshalling system from tusystem, mars haling roller will rise up and part bricks to ensure the code system to pick up bricks

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。