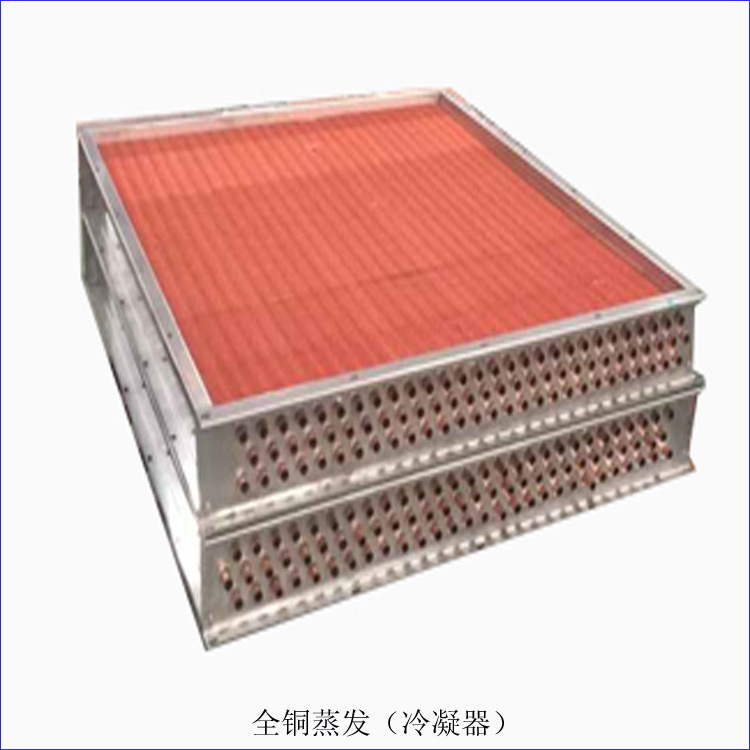

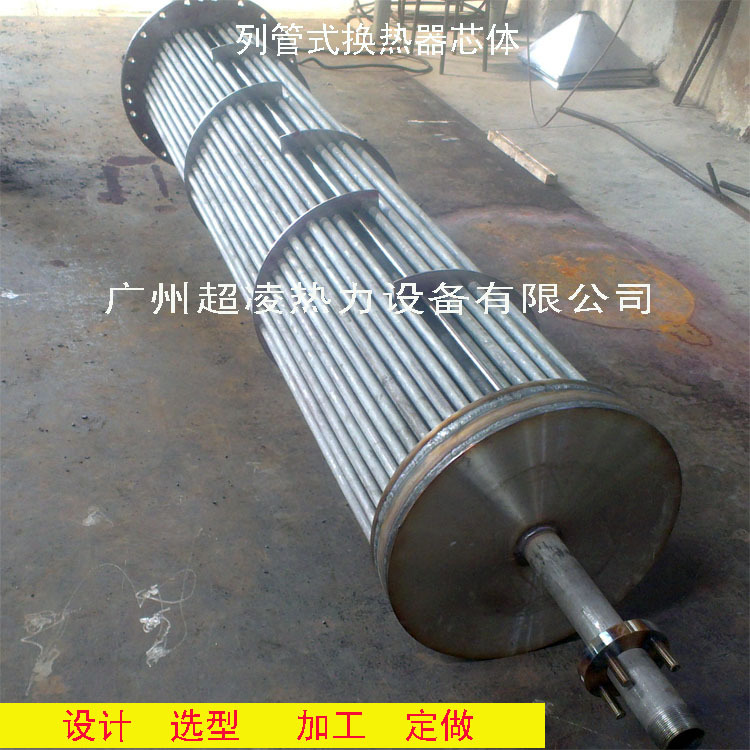

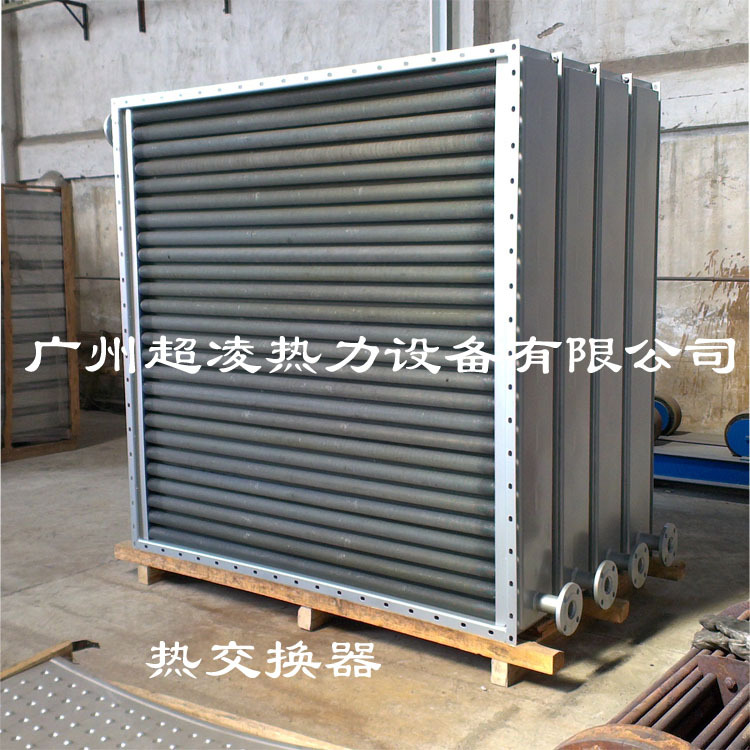

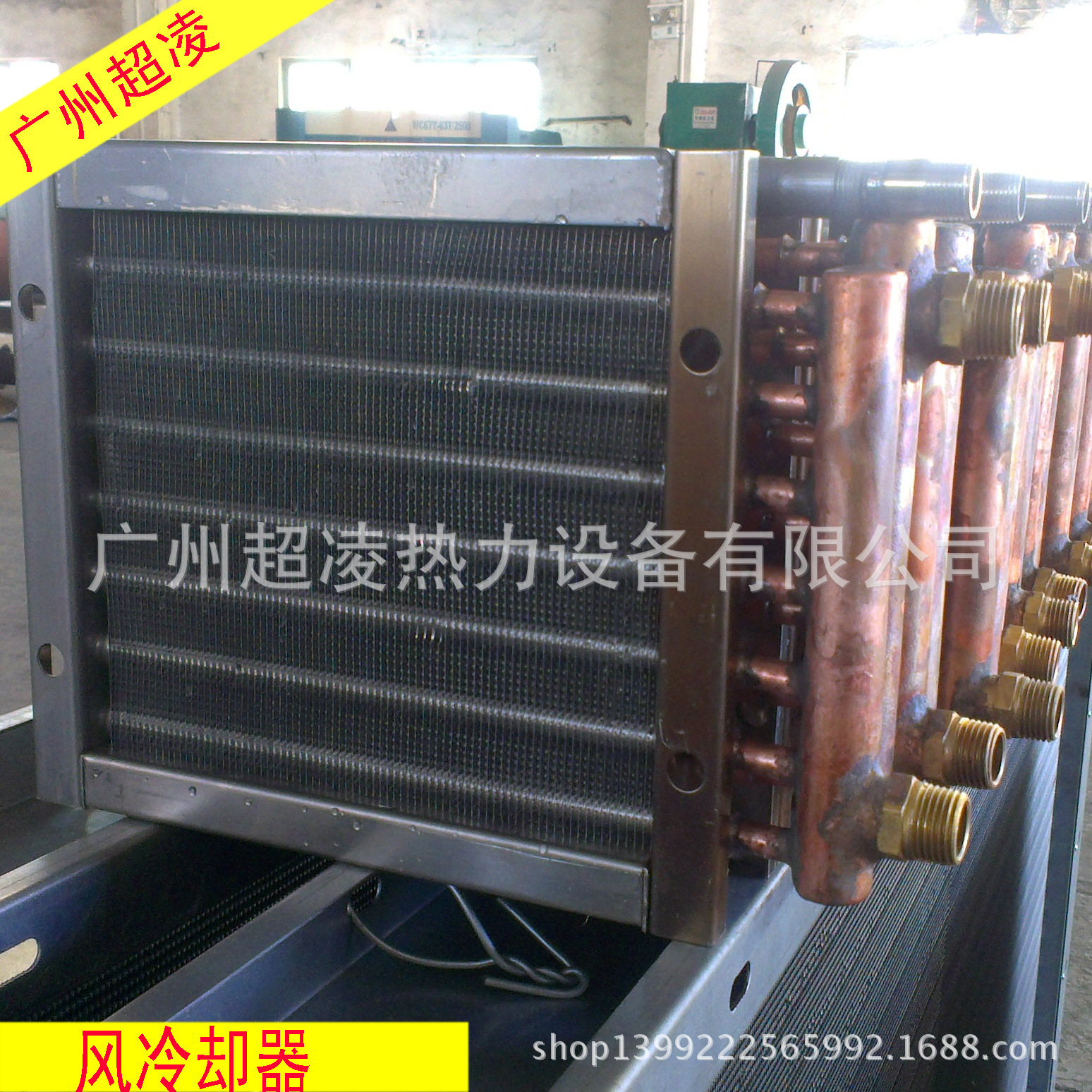

TLS型散熱器是由紫銅管串鋁片式的高效熱交換器,它采用瞭選進的機械脹管和橋式波紋雙翻邊鋁肋片結構。機械脹管使紫銅管與鋁片接觸緊密,橋式波紋使流體的紊流狀態更好,大大提高瞭換熱系數,先進的結構加上水路行程、管距、片距設計合理,從而具有良好的傳熱性能,空氣阻力小,結構緊湊,重量輕等特點。它可廣泛應用於空調製冷(蒸發器、冷凝器)、通風采暖、空氣加熱、染整烘乾、除濕乾燥工程等,特別適用於低溫差表冷器的換熱工況。

TLS型散熱器換熱元件采用φ16x1.0mm或φ10x0.5mm紫銅管串0.15~0.2mm厚鋁片製成,有2.0~3.2mm多種片距,可滿足不同工況需要。

耐壓高達2.0Mpa,溫度達185℃。

TLS type radiator is composed of copper on aluminum chip high efficiency heat exchanger adopts the advanced mechanical expansion pipe and a bridge type corrugated double flanged aluminum fin structure. The mechanical expansion of the copper tube and aluminum plate contact close, the bridge type ripple make the flow of the fluid turbulent state better, greatly improve the heat transfer coefficient, advanced structure and water travel, pipe distance, piece distance design is reasonable, so as to have good heat transfer performance, air resistance is small, compact structure, light weight and so on. It can be widely used in air conditioning refrigeration (evaporator, condenser), ventilation heating, air heating, dyeing and finishing, drying and drying, etc., in particular, for low temperature differential heat transfer conditions.

TLS type radiator for heating element using phi 16x1.0mm or phi 10x0.5mm copper on 0.15~0.2mm thickness of the aluminum sheets and distance with 2.0~3.2mm a variety of chip, can meet the requirements of different working conditions.

Pressure up to 2.0Mpa, the temperature reached 185.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。