技術信息

L5M的一個型號

容量

1毫升高達12公升。

電機組

強大的兩組散熱設計,安靜和連續操作而設計的。

電機組

1HP(750W)220伏,單相(110伏可選),50/60赫茲。標稱最大速度為8000轉滿負荷情況下(6000RPM)。

速度控製

ON / OFF開關積分無級變速電子調速控製。

電動升降臺架

混合裝置,可毫不費力地升高和降低使用的馬達裝置上的按鈕控製。

構造材質

所有接觸物液部件級316不銹鋼與特級軸襯,合金或聚四氟乙烯。

L5系列混頻器是在一個嚴格的,易於清潔,非芯片白色尼龍塗層完成。平底涵蓋瞭一個可拆卸的防滑墊,這是耐大多數溶劑。

In-Line Workheads

General Purpose Disintegrating Head

Used for a wide range of applications, this head will give the greatest throughput. Suitable for the blending of liquids of similar or greatly varying viscosities, its uses include the disintegration of solid and semi-solid materials.

Used for a wide range of applications, this head will give the greatest throughput. Suitable for the blending of liquids of similar or greatly varying viscosities, its uses include the disintegration of solid and semi-solid materials.

Square Hole High Shear Screen™

The configuration and fine internal tolerances of this stator provide exceptionally high shear rates which are ideal for the rapid size reduction of soluble and insoluble granular solids. It is also suitable for the preparation of emulsions, gels and thickeners and fine collodial suspensions.

The configuration and fine internal tolerances of this stator provide exceptionally high shear rates which are ideal for the rapid size reduction of soluble and insoluble granular solids. It is also suitable for the preparation of emulsions, gels and thickeners and fine collodial suspensions.

Slotted Disintegrating Head

For the disintegration of fibrous materials such as animal and vegetable tissue, as well as the disintegration and solubilization of “elastic” materials such as rubbers and polymers.

For the disintegration of fibrous materials such as animal and vegetable tissue, as well as the disintegration and solubilization of “elastic” materials such as rubbers and polymers.

Emulsor Screens

These screens are suitable for liquid/liquid preparations and are especially useful for all emulsions. Emulsor screens are available in fine, medium or coarse perforations.

These screens are suitable for liquid/liquid preparations and are especially useful for all emulsions. Emulsor screens are available in fine, medium or coarse perforations.

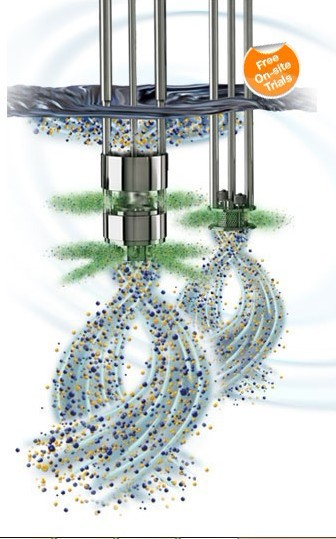

How It Works

The advantages of Silverson's high shear rotor/stator laboratory mixer over simple conventional stirrers or agitators stem from the multistage mixing/shearing action as materials are drawn through the specially designed Silverson workhead - the heart of every machine.

Stage 1

The high-speed rotation of the rotor blades within the precision machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

The high-speed rotation of the rotor blades within the precision machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead wher they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Centrifugal force then drives materials towards the periphery of the workhead wher they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

Stage 4

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid's surface.

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid's surface.

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。