VDI Turret (STD / OPT)

thermal deformation due to temperature rise on the shaft during long time high speed operation. So that its high speed and heavy-duty cutting characteristics reach to the ultimate.

Features

?Top quality casting provides excellent stability and precision.

?High rigidity, 45° slant bed design for high chip discharge it specially suitable for automation factory and automatic chip discharge so that it improves load-unload very easily for the workpiece and improves stability of cutting.

?All axes are installed with sliders to reduce resistance. The automatic lubrication and AC servo motor improve precision and reduce maintenance cost.

?Detachable coolant tank extends the service life of coolant and improves maintainability.

?Detachable shaft housing reduces noise, vibration, and heat deformation.

?It is designed based on human factor for best operation, inspection, and maintenance.

|

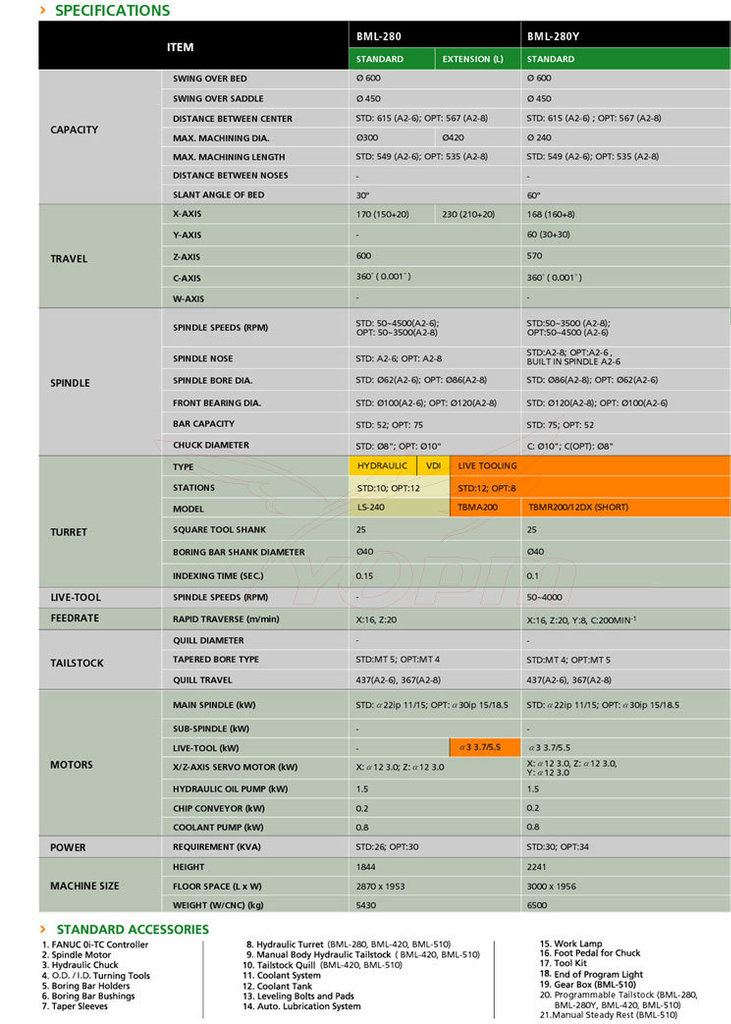

Specifications

ITEM | BML-510 | Capacity | Swing over bed | Ø 630 | | Swing over saddle | Ø 455 | | Distance between center | STD:1891 (A2-8) ; OPT:1863 (A2-11) | Max. machining dia. | Ø 510 | Max. Machining length | 1526 (A2-8); OPT:1475 (A2-11) | Travel range | X-axis | 290 (255+35) | Z-axis | 1590 | | Spindle | Spindle speed (rpm) | STD:50~2500(A2-8) ; OPT:50~2000(A2-11) | | Spindle nose | STD:A2-8; OPT:A2-11 | | Spindle bore dia. | STD:Ø 105(A2-8) ; OPT: Ø134(A2-11) | | Front bearing dia. | Ø 130 (A2-8) ; OPT: Ø180(A2-11) | | Bar capacity | STD: Ø 90 (A2-8); OPT: 116 | Turret | Type | Hydraulic | VDI | Live-tooling | Stations | STD:10, OPT:12 | Model | LS-250H | TBMA250DX | | Square tool shank | 25 | | Boring bar shank diameter | Ø40 | Ø50 | Indexing time (sec) | 0.15 | Feedrate | Rapid traverse (M/min) | X: 20, Y: 20 | Tailstock | Quill diameter | Ø120 | Tapered bore type | STD:MT 5 | Quill travel | 120 | Motors | Main spindle (kW) | STD:22/26; OPT: 30/37

C-axis: 18.5/22 | Live-tool (kW) | - | α3 3.7/5.5 | X/Z-axis servo motor | X:α12 3.0, Z:α12 3.0 | Hydraulic oil pump (kW) | 2.25 | | Chip conveyor (kW) | 0.2 | Coolant pump (kW) | 0.96 | Power | Requirement (KVA) | 30 | Machine size | Height | 2200 | Floor space (LxW) | 5325x1950 | 54801950 | Weight (w/cnc) | 8500 | 8775 |

|

一、 供貨範圍

- 最大旋轉直徑: 630 mm

- 最大加工直徑×長度: 510×1,526 mm

- X/Z-軸最大行程: 290 / 1,590 mm

- X/Z-軸快速位移:20 / 20 M/min

- FANUC 0i-TD控制器

- A2-11主軸,主軸轉速2,500轉

- 12”三爪油壓夾頭與迴轉缸

- 拉桿孔徑:Ø 90mm

- FANUC AC主軸馬達: α 22 (22/26 Kw)

10.X/Z-軸伺服馬達 α22 (X:4kw,Z:4kw) 11.10支刀直立式油壓刀塔 12.外掛式兩段變速齒輪箱 13.刀具刀柄規格:□32*32mm 14.鏜刀座規格:Ø 50 mm 15.鏜刀柄套 16.斜度套筒 17.全罩式防濺鈑金 18.切削冷卻系統 19.全自動潤滑系統 20.基礎調整螺絲及墊片 21.斜板5組 22.鏜刀座× 5個 23.外徑刀座× 2個 24.工作燈 25.工具箱 26.變壓器 27.鐵屑輸送機+集屑車 28.夾頭腳踏開關 29.MT.5活動頂心1支 30.黃油槍1支 31.操作、維護手冊(奕達) 32.零件手冊(奕達) 33.電路圖(奕達) 34.操作手冊(FANUC) 35.維修手冊(FANUC) 36.FANUC保固二年 37.機械零件保固一年 (不含寄送運費)

二、 機械規格 項 目 | 單位 | BML-510 | 工作範圍 | 床身最大旋徑 | mm | Ø 630 | 鞍麵旋徑 | mm | Ø 455 | 最大加工直徑×長度 | mm | Ø 510 × 1,526 | 床 身 | 床身水準斜度 | 度 | 45 ° | X/Z軸最大行程 | mm | 290 / 1,590 | X/Z軸伺服馬達 | kw | X:α22/4.0kw,Z:α22/4.0kw | X/Z軸快速進給率 | m/min | 20 / 20 m/min | 主 軸 | 主軸前端軸承孔徑 | mm | Ø 130 | 拉桿孔徑 | mm | Ø90 | 主軸鼻端形式 | | ASA A2-11 | 主軸內孔錐度 | | 1/20 | 主軸馬達 | kw | α22 22 / 26 kw | 主軸轉速 | rpm | 2,500 rpm | 夾頭尺寸 | inch | 12”三爪油壓夾頭 | 刀 塔 | 型式 | | 直立式油壓刀塔 | 刀具數 | pc | 10 pcs | 四方刀具刀柄規格 | mm | □32 × 32 | 鏜刀座規格 | mm | Ø 50 | 油壓尾座 | 心軸軸徑 | mm | Ø 125 | 頂心形式 | | 活動頂心 | 頂心錐度 | | MT 5 | 心軸行程 | mm | 120 | 驅動馬達 | 冷卻裝置馬達 | kw | 0.96 kw | 油壓馬達 | kw | 2.25 kw | 排屑機馬達 | kw | 0.2 kw | 精度 ISO230-2 | 定位精度(Z/X) | mm | ±0.006mm | 重複定位精度(Z/X) | mm | ±0.005mm | 一般規格 | 電 源 | w | 380Volts/30KVA/50Amps | 外形尺寸(W × D × H) | cm | 532×195×220 | 重量 | kg | 約9,770 kg |

|