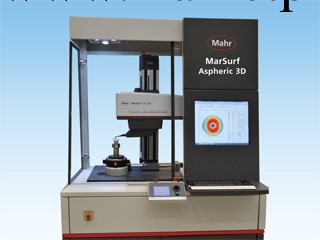

MarSurf LD 130 Aspheric / LD 260 Aspheric High-precision 2D/3D Measuring Station for Measurement and evaluation of Optical Components - Measuring range up to 260 mm

- High measuring speed

- Checking topography during the first machining operations

- Chip-coded bionic probe arms

|

| | | |

| Features - Properties of the horizontal axis (X) |

| | - Traversing length: 0.1 mm up to 130 mm / 260 mm

- Positioning speed: 0.02 mm/s up to 200 mm/s

- Measuring speed: 0.02 mm/s to 10 mm/s (for roughness measurement recommended: 0.1 mm/s to 0.5 mm/s)

- Measuring point spacing: 0.05 µm up to 30 µm

- Max. number of points in one scan: 2.6 Mio. points LD 130; 5.2 Mio. points LD 260

- Resolution: 0.8 nm

- Uncertainty X-axis display: ± (0.2+l/1000)μm; l in mm

|

|

| Features - Technical data probe systems (measuring direction Z+ / Z-) |

| | - Probe measuring range: 13 mm (100 mm probe arm) ; 26 mm (200 mm probe arm)

- Resolution: 0.8 nm

- Measuring force: 0.5 mN up to 30 mN

|

|

| Features - Option 3D Measuring station |

| | - Measuring time: 5 to 10 minuten, diameter up to 100 mm

- C-axis: Measuring and positioning speed < 120°/s

- C-axis: axial and radial run out< 100 nm, at 50 upr

|

|

| Application in optical industry |

| | Contour and roughness measurement of: - spherical and aspherical lenses

- cylinder lenses

- lens mounts

- housing and other mechanical components

|

|