產品特點:

1、更換安裝模具可節省更多時間

save more time for mold changing and clamping

2、操作簡單方便,操作工不需要特殊的技能就可在機器外部更換模具。

without special skills,operators can change mold Simply and conveniently on the outside of the machine.

3、最大限度地利用機器的有效空間,實現小註塑機加工大模具

Small injection molding machine process large mould by the best use of the effective machine space

4、使用時效持久,不需要對機器模板及模具背板進行任何修改

Stable performance, no need to modify the machine platen and the mold backboard.

5、大大降低人工成本和員工的工作強度。

Greatly reduce labor costs and the working strength

6、磁力強勁且恒定,無需持續的電能,也不會產生熱量

Constant and strong force,without consuming electrical energy or generating any heat.

7、降低庫存,減少廢料

Reduce inventory,reduce scrap

8、幾乎沒有維護成本

Almost no maintenance costs

技術參數:

輸入電源 Power input | 充(退)磁時間 (De)magnetizing time | 接近傳感器最大感應值 Proximity sensor threshold level | ||||

15千瓦(220伏,50赫茲,單相)15KVA(220V,50Hz,single phase) 25千瓦(380伏,50赫茲,兩相)25KVA(380V, 50Hz ,2 phase) | 每個通道0.3秒 0.3s/per channel | 0.2mm | ||||

| ||||||

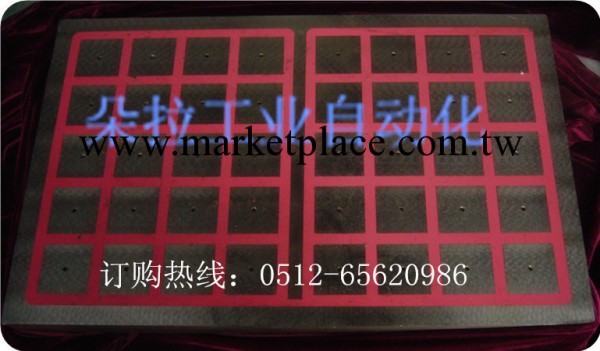

磁極尺寸 Pole size | 單磁極磁力 Each pole force | 磁性模板厚度 Magnetic chuck thickness | 最大工作溫度(模具接觸麵) Max working tempreture(contact surface with mold) | 磁力作用深度 Depth of magnetic force | ||

75*75mm | 7.5KN | 38mm | 120℃ | 20mm | ||

50*50mm | 3.5KN | 56mm | 10mm | |||

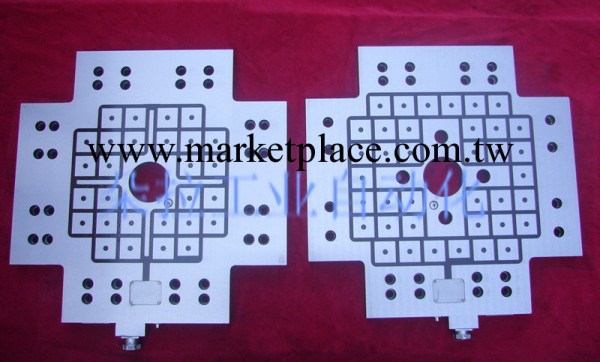

標準配置:supply specification

1、 整塊鋼板而成的磁性定模扳和動模板,帶有中心定位環、頂出孔、固定孔,每個模板配一個以上的接近傳感器;

Two magnetic modules in steel monoblock for fixed and movable platen in the machine,with centering ring ,fixing and ejectors holes,

and more than one proximity sensors in each module.

2、 電控單元,IP54電控箱含PLC接口、磁性檢測、電流控制、位置檢測等;

Electronic control unit,IP54 cabinet with PLC interface, Magnetic detection, Current control, position detection.

3、 含充/退磁按鈕、指示燈、安全鑰匙的遙控器;

Remote controller with MAG/DEMAG button,signal lamps and safe keys.

4、 充/退磁電纜、電源電纜、接插頭;

Cable for MAG/DEMAG,power cable,connectors.

5、 固定螺栓

Set of fixing bolts .

6、 產品說明書及安全操作指引

product manual and safety operating instruction.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。