耐高溫 韌性好 耐火材料 陶瓷用棕剛玉

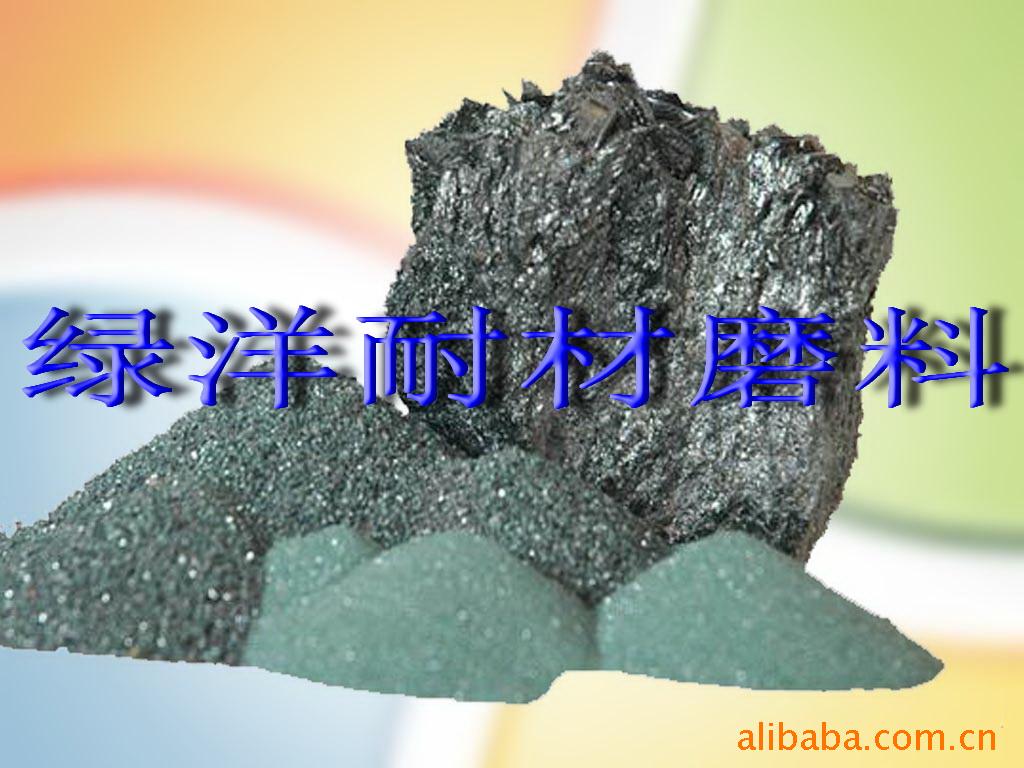

金剛砂,SiC,學名碳化矽。碳化矽硬度僅次於金剛石、碳化硼和立方氮化硼,在無機材料中排行第四。目前已能通過熱壓燒結法制得高致密度的碳化矽。它具有很高的強度及良好的抗氧化性能,在高溫下不變形,可作為高溫燃氣輪機上的渦輪葉片,也可作耐磨的密封材料,還可作火箭尾噴管的噴嘴及輕質的防彈用品等。晶胞為麵心立方結構,每個晶胞含有4個C原子4個Si原子。與金剛石結構類似。純的是無色晶體。密度3.06~3.20。硬度很大,大約是莫氏9度。一般的是無色粉狀顆粒。磨碎以後,可以作研磨粉,可制擦光紙,又可制磨輪和砥石的摩擦表麵。由砂和適量的碳放在電爐中加強熱制得。

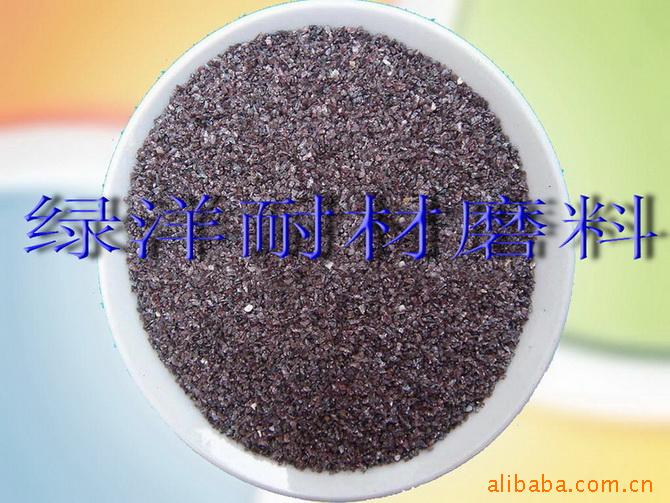

天然金剛砂又名石榴子石,系矽酸鹽類礦物。經過水力分選,機械加工,篩選分級等方法制成的研磨材料。生產使用歷史悠久,古代我國就有使用金剛砂研磨水晶玻璃,各種玉石的史例。十九世紀四十年代又遠銷東洋。分粗目,中目,細目三大類。其中粗目為黑紅色,中目為淡紅色,細目為紅白色,各種目數粒度均勻,顆粒形狀均一,成棱叫角晶體,有鋒利的邊緣,磨削力高。供石材類工業研磨大理石及其它軟質材料。玻璃類工業研磨玻璃毛邊,電視機顯像管,光學器械,鏡片,棱鏡,鐘表用玻璃等。金屬類工業噴砂,除銹,研磨。印刷工業研磨膠版,以及輕工業加工塑樣,皮革,砂紙等用途。

天然金剛砂的磨削力略低於電爐白剛玉,但其任性強,具有介殼狀段口之特性,其優點是磨件的光潔度高,砂痕少而淺。磨麵細而均勻,可提高產品質量,為本品的獨特之處。天然金剛砂的研磨時間短,效益高,價格低廉,可彌補壽命短的不足

棕剛玉以優質鋁礬土為原料,無煙煤,鐵霄,通過采用在電弧冶煉。爐2200℃以上高溫中提純、除雜、結晶、分選、破碎、磁選、篩分等加工手段制成各種顆粒尺寸的產品。其質地致密、硬度高,粒形成球狀,適用於制造陶 瓷、樹脂高固結磨具以及研磨、拋光、噴砂、精密鑄造等,還可用於制造高級耐火材料 。

棕剛玉具有純度高,結晶好,流動性強,線膨脹系數低,耐腐蝕的特點。經數十傢耐火生產企業實踐驗證,該產品在應用過程中具有不起爆、不粉化、不開裂的特點。

產品粒度按國際標準以及各國標準生產,可按用戶要求粒度進行加工。通用粒度號為 F4~F320,其化學成份視粒度大小而不同。突出的特點是晶體尺寸小耐沖擊,因用自磨機 加工破碎,顆粒多為球狀顆粒,銳石牌棕剛玉具有純度高,質地致密,堆積密度大,自銳性強,韌性好,磁性物含量特低的特點,用其制成的磨具磨削鋒利,發熱率低,磨削比高,且使用時沾附少;制成的燒結磨具具有燒成後顏色深藍、不起網狀裂紋、無銹斑的特點,適用於制造陶瓷、樹脂高固結磨具以及研磨、拋光等。

產品 名稱 | 規格型號 | 主要指標 | 密度 | 外觀 | 用途

| 包裝 | 價格 | |||

AL203 | Fe2O3 | SiO2 | ||||||||

棕

剛

玉 | 一級 | ≥ 95 | ≤0.3 | ≤1.5 | 3.85 | 棕紅色顆粒 | 耐火材料,精拋 | 25KG/袋 | 3300元/噸 | |

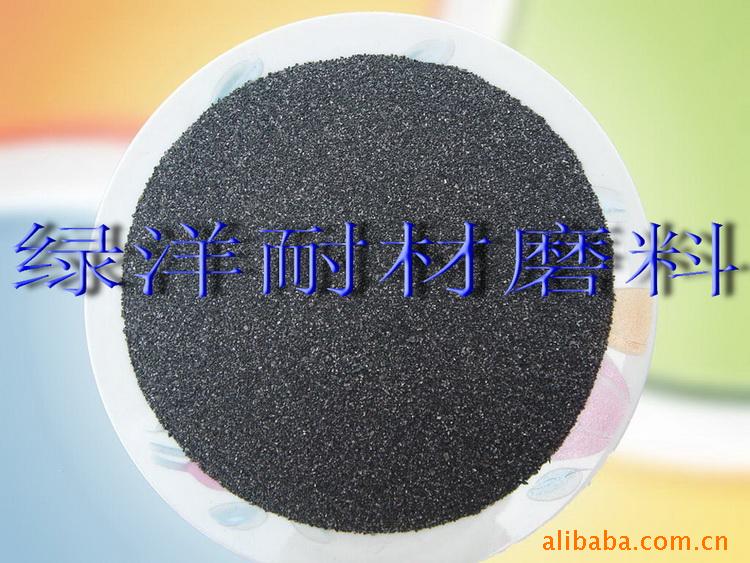

次一級 | ≥90 | ≤0.3 | ≤1.5 | 3.85 | 黑色顆粒 灰色粉狀 | 拋光,研磨 | 25KG/袋 | 2800元/噸 | ||

二級 | ≥85 | ≤0.3 | ≤1.5 | 3.85 | 黑色顆粒 灰色粉狀 | 研磨、砂輪,切割片, 噴砂 | 25KG/袋 | 2200元/噸 | ||

次二級 | ≥80 | ≤0.3 | ≤1.5 | 3.85 | 黑色顆粒 灰色粉狀 | 拋光,研磨 | 25KG/袋 | 1700元/噸 | ||

三級 | ≥70 | ≤0.3 | ≤1.5 | 3.85 | 黑色顆粒 灰色粉狀 | 地坪 | 25KG/袋 | 950元/噸 | ||

|

|

|

|

|

|

|

|

|

|

|

F為固結磨具及噴砂用規格 P為塗附磨具用規格W為微粉,320#即W40

常用規格:磨料磨具F 1#-63# 4#—80# 90#—150# 180#—240#

段砂 0-1mm,1-3mm,3-5mm 5-8mm,8-12mm 25-0mm 10-0mm

50-0mm 30-0mm

細粉 180#-0, 200#-0 320#-0

物理性能:晶形三方晶系

化學性質 兩性與酸反應 在王水中和氫氟酸中稍有腐蝕與堿反應 僅與強堿熱溶液稍有反應 氧化還原效果 否

硬度 努譜硬度 2000 - 2200 Kg/mm2 莫氏硬度 9.0

顏色 深C

最高使用溫度 1900 C

SiC, its scientific name is silicon carbide and the hardness is next to diamond, boron carbide and cubic boron nitride, ranked fourth in the inorganic materials. Currently, high density silicon carbide can through sintering process with hot pressing. It has high strength and good oxidation resistance, without deformation at high temperatures, can be used as turbine blades of high-temperature gas turbine, but also can be used for wear-resistant sealing material and makes the rocket nozzle and light bullet-proof appliances. Its structure cell has a face-centered cubic lattice structure; each cell contains four C atoms four Si atoms, similar with the diamond structure. Pure SiC is colorless crystals. Density: 3.06 ~ 3.20. It has a great hardness, about 9 Mohs degree. Generally, it is colorless powder particles. After grinding, it not only used for grinding flour, but also for polished paper and the friction surface of grinding wheel and whetstone.

Natural corundum, also known as garnet, belongs to the department of silicate minerals. It is good abrasive material made by hydraulic sorting, mechanical processing, and classification methods. It has a long usage history, in ancient China, people used corundum to grind crystal glasses and a variety of jade.

With bauxite, carbon material, iron filings as raw materials, Brown Fused Alumina is restored and obtained through the melting of the brown the brownartificial corundumin the furnace above 2200 ℃, and made of a variety of particle sizes products by purifying, crystallization, sorting, crushing, magnetic separation and screening methods. With its dense texture, high hardness and the formation of spherical particles, it is suitable for the manufacture of ceramics and resin, as well as the high-Bonded Abrasives grinding, polishing, sand blasting, precision casting and so on, also can be used to manufacture high-grade refractory material.

Brown Fused Alumina has high purity, good crystalline liquidity, low coefficient of linear expansion, corrosion-resistant and other characteristics. Dozens of refractory manufacturers have proved in practice that the product has not detonate, non-powder, non-cracking characteristics in the application process.

Particle size is in accordance with international standards and can be processed as requirements. Universal size: No. F4 ~ F320, its chemical composition varies depending on grain size. Its prominent feature is the small crystal size, impact resistance and spherical particles. This product has high purity, dense texture, large bulk density, strong self-sharpening, good toughness, low level magnetic material content and other characteristics.

F for Bonded Abrasives and sandblasting specification; P for coated abrasives specifications; W for the powder, 320 # that is the W40

Common Specifications: Abrasives F 1 # -63 # 4 # -80 # 90 # -150 # 180 # -240 #

Sand 0-1mm ,1-3mm ,3-5mm 5-8mm ,8-12mm 25-0mm 10-0mm

50-0mm 30-0mm

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。