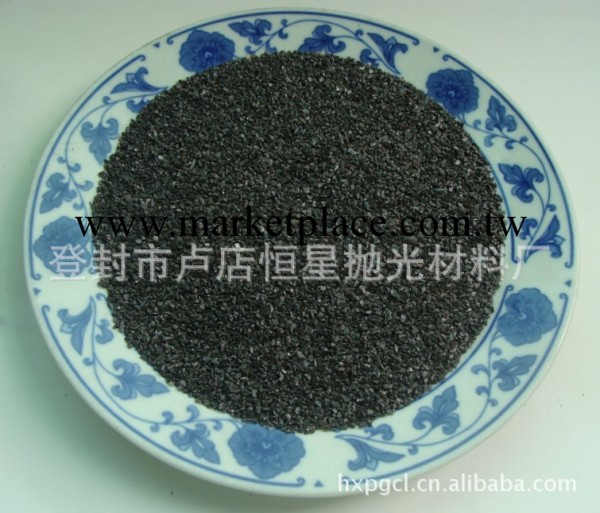

碳化矽的用途 1有色金屬冶煉工業的應用 利用碳化矽具有耐高溫,強度大,導熱性能良好,抗沖擊,作高溫間接加熱材料,如堅罐蒸餾爐,精餾爐塔盤,鋁電解槽,銅熔化爐內襯,鋅粉爐用弧型板,熱電偶保護管等. 2.鋼鐵行業方麵的應用 利用碳化矽的耐腐蝕,抗熱沖擊耐磨損,導熱好的特點,用於大型高爐內襯提高瞭使用壽命. 3.冶金選礦行業的應用 碳化矽硬度僅次於金剛石,具有較強的耐磨性能,是耐磨管道,葉輪.泵室.旋流器,礦鬥內襯的理想材料,其耐磨性能是鑄鐵.橡膠使用壽命的5—20倍,也是航空飛行跑道的理想材料之一. 4.建材陶瓷,砂輪工業方麵的應用 利用其導熱系數.熱輻射,高熱強度大的特性,制造薄板窯具,不僅能減少窯具容量,還提高瞭窯爐的裝容量和產品質量,縮短瞭生產周期,是陶瓷釉麵烘烤燒結理想的間接材料. 5.節能方麵的應用 利用良好的導熱和熱穩定性,作熱交換器,燃耗減少20%,節約燃料35%,使生產率提高20-30%,特別是礦山選廠用排放輸送管道的內放,其耐磨程度是普通耐磨材料的6—7倍.

碳化矽產品性能指標 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The use of silicon carbide

1. Application in non-ferrous metal smelting industry

With its high temperature, high strength, good thermal conductivity and impact resistance it can be used for high-temperature indirect heating materials, such as distillation furnace, distillation furnace trays, aluminum electrolysis tank, copper melting furnace linings, zinc furnace arc plate and thermocouple protection tubes.

2. The application in iron and steel industry

With its anti-corrosion, thermal shock resistance, good thermal conductivity and other characteristics, it can be used for large blast furnace lining to increase service life.

3. The applications in metallurgical beneficiation industry

The hardness of silicon carbide is only next to diamond. Silicon carbide has a strong wear resistance, is the ideal material for making wear-resistant pipe, impeller, pump room, hydrocyclone and the ore lining of ore bucket.

4. The application in building, ceramics and wheel industry

With its thermal conductivity, heat radiation, high heat intensity characteristics, it can be used for making kiln sheet, which can not only reduce the kiln capacity, but also increase the installed furnace capacity and product quality and shorten the production cycle.

5. The application in energy saving

It can be used for making heat exchanger for its good thermal conductivity and thermal stability. The fuel consumption can be reduced by 20% and it saves fuel by 35%, thus it increases the productivity by 20-30%, its wear-resistant is 6-7 times the normal wear-resistant materials especially in the usage in mining pipeline.

Product performance index:

Item | Units | Indicators | |

SICRSIC | PCRBSC | ||

Density | g/cm3 | 2.60-2.68 | 3.02 |

Porosity | % | ≤ 17 | 0 |

Flexural strength | Mpa (20 ℃) | ≥ 90 | 220 |

Mpa (1200 ℃) | ≥ 100 | 230 | |

Coefficient of thermal expansion | 10-5 K | 4.8 | 4.8 |

Thermal conductivity | W / mk | 23 | 45 |

Young modulus | Gpa (20 ℃) | 240 | 420 |

Max. Operating Tem | ℃ | 1650 | 1320 |

SIC | % | ≥ 99 | 80 |

Si + SiO2 | % | ≤ 0.6 | 19 |

| % | ≤ 0.1 | 0.15 |

Acid resistance |

| Not reacting with any strong acid (except that when concentrated phosphoric acid at 300 ℃) | There are weak reactions with the strong acid reaction, and when the concentrated phosphoric acid at 300 ℃they has a strong reaction |

Alkali |

| No reaction with the alkali | Reaction with alkali |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。