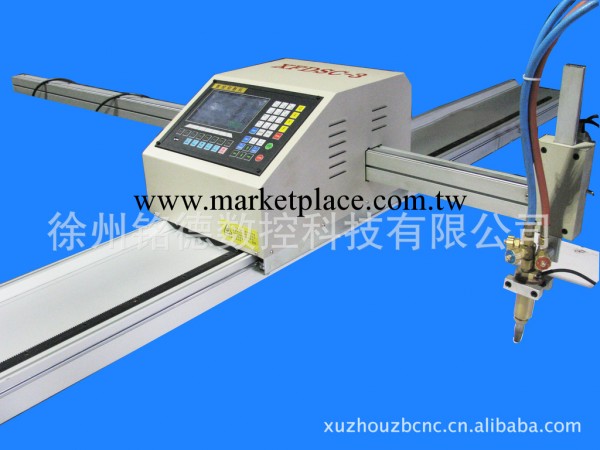

便攜式數控火焰/等離子切割機 MingDePortable CNC Flame/Plasma Cutting Machine | ||||

型號Model | MD-1020 | MD-1225 | MD-1525 | |

輸入電源 Power source | 220±10%VAC 50/60Hz 220W | |||

切割方式 Cutting mode | 氧氣/丙烷或乙炔;可配置等離子切割機 O2/C3H8or C2H2, Plasma available | |||

有效切割范圍(寬×長)mm Effective cutting range(mm) | 1000×2000 | 1200×2500 | 1500×2500 | |

導軌 長×寬×厚mm Track L×W×H(mm) | 2500×273×60 | 3000×273×60 | 3000×273×60 | |

配置的軌枕數量 Track Holder Quantity | 2 | 3 | 3 | |

軌枕長×寬×厚mm Track Holder L×W×H(mm) | 500×80×40 | |||

切割速度mm/min Cutting speed(mm/min) | 0-3500(最大4000) 0-3500 (Max 4000 available) | |||

切割厚度(火焰)mm Cutting thickness(Flame)(mm) | 5-150(氧氣+丙烷 或 乙炔) 5-150 (O2/C3H8or C2H2) | |||

切割厚度(等離子)mm Cutting thickness(Plasma)(mm) | 視客戶等離子電源而定 In terms of plasma power source | |||

運行精度 Move precision | ±0.2mm/m | |||

割槍和調高 Torch | 火焰,電動調高(±60mm) Flame,electric height adjustment(±60mm) | |||

主機重量kg Host weight(kg) | 19 | |||

整機重量 Total weight(kg) | 120 | 130 | 140 | |

燃氣壓力Mpa Gas pressure(Mpa) | 最大0.1 Max0.1 | |||

氧氣壓力Mpa Oxygen pressure(Mpa) | 最大0.7 Max0.7 | |||

適用燃氣種類 Type of gas | 丙烷、乙炔 Propane, Ethine | |||

急停按鈕Emergency stop | 有/Yes | |||

環境溫度 Working temperature | -5~45℃ | |||

相對濕度 Relative humidity | <95%無冷凝 <95% No condensing | |||

備註:*本產品在用戶無特殊要求時,出廠標配統一為2號丙烷割嘴一個 Standard configuration is 2#propane cutting nozzle if no special requirement. | ||||

*縱向導軌長度可按客戶要求訂制加長 Tailor-made track if request. | ||||

功能說明 |

* 5.7寸高分辨率液晶顯示屏,人性化操作界麵,全中文/英文菜單,優化操作步驟,屏幕下方標註有操作提示,靈活高效,簡單易學。5.7”high-resolution LCD, human-oriented interface, Chinese and English menu, Optimize operation procedure, tips under the screen, efficiency, flexibility, easy-going and easy learning. |

* 7寸800*600高分辨率1600萬色彩色高亮度液晶屏。 7" high-resolution LCD with 800*600pix,1600 color and high-bright. |

*支持EIA代碼(即G代碼)及FastCAM等各類套料軟件;中英文菜單,適合國內外各類操作人員。 Support the EIA code (G code) and all types of nesting software such as FastCAM,etc. English and Chinese menu system. |

*自帶45種常用圖形庫(包括網格圖形),可手工設置片尺寸和孔尺寸,直接切割,無需編程。 Internal 45 types of basic figures(including the grid graphics), enable to setting piece size and pore size, directly do cutting process, no need programme. |

*采用32位高性能CPU,運用實時多任務控制技術和DSP高速、高精度插補控制技術,工作時高穩定性,高速運行,低噪音。 32 bits high speed and characteristics, Multi-task Controlling System and DSP high-speed, high-precision interpolation control technology, to increase stability and high speed with low noise. |

*通用U盤傳輸G代碼文件(切割軌跡文件),並可傳輸系統升級文件,使系統功能隨時更新,方便快捷。 U-disk transfer G-code files(cutting track file), also able to transfer system upgrade files to guarantee the latest function to be installed anytime, convenient and efficient. |

* 256M超大容量存儲空間,能存儲超過5000個復雜異型切割文件;滿足各種復雜程序的運行與加工,輕松處理大程序的運行。 256M large memory storage, could save more than 5,000 files; easily operating huge and multiple procedure. |

*圖型任意角度旋轉、比例縮放、X或Y鏡像、矩陣排列、空走、可手工選行及選號等日常操作中的實用功能。 Graphic scale, rotate, mirror image, matrix permutation, idling, selec line or line number, etc, Which will frequently be used. |

*根據鋼板厚度,在轉角處可自動限速,有效防止過燒。支持邊緣切割、偏移切割,對較厚的鋼板可減少預熱時間,並可避免因排料計算錯誤而造成的板材浪費。 Automatically control the cutting speed to avoid over-burning according to plate thickness. Possible to edge cutting, offset cutting, to avoid wasting of meal sheet caused by calculation errors. |

*圖形放大/縮小,放大狀態下可實時跟蹤切割點。自定義全部輸入輸出端口的類型(常開或常閉)和編號。 Graphics zoom-in or out, and tracking the cutting point dynamically while zoom-in status. Customize the type of all input and output ports (normally open or close) and the number |

*自診斷系統所有IO狀態和按鍵狀態,方便檢查和排除故障。單獨或批量導入導出程序,參數備份及恢復,日期,星期,時鐘顯示。 Self-diagnostic system for all IO and keyboard status, convenient for inspection and trouble-shooting. Export files, parameter backup, online upgrade; date, week and time display. |

*支持氧燃氣、等離子及演示模式;各類加工參數齊全,可滿足不同工藝需求。 Oxygen gas, plasma and presentation modes; various inside machining parameters for match various demand. |

*氧燃氣和等離子IO分開控制;氧燃氣自動調高,兩級預熱,三級穿孔;等離子弧壓反饋,定位反饋,轉角自動關閉弧壓調高。Separately control oxygen gas from plasma IO; adjust the height of oxygen gas automatically, two grades of preheat, three grates of perforation; plasma arc voltage feedback, position feedback, automatically shut down arc voltage in the corner. |

*斷電、斷點數據存儲及恢復功能、退回功能、急停按鈕,自動恢復到未斷電前的狀態,有效避免誤操作。 Auto-memory and recovery in case of power-off or point break, return function, emergency stop button, recover to the pre-status automatically, avoid mis-operation. |

*高細分步進電機采用高細分驅動器,噪音低、精度高、運行平穩。 High-subdivision stepper motor driver, low noise, high running precision, and movement smoothly. |

*自動割縫補償,割槍移位,割槍穿孔停留,預熱時間智能記憶,鍵盤診斷,溫控風扇。標配電動高度調節裝置及萬能割槍夾緊器。 Cutting slot compensation auto-setting function,cutting gun movement, cutting gun perforation remain, preheated time auto-memory, keyboard diagnostication, temperature-controlled fan. Auto-adjust height of cutting gun and multiple torch clamp structure. |

*穩定性強,具有超強的等離子高頻抗乾擾能力。*切割速度最大可調到每分鐘3.5米,能滿足快速等離子切割的需求。 Strong stabilization, effective shield plasma high frequency interference. Max cutting speed 3500mm/min, apply to plasma cutting. |

*機箱采用全鋼防磁結構,完全屏蔽電磁輻射,真正抗乾擾、防靜電。 All steel and anti-magnetic outside frame of NC system and host to ensure reliable and stable operation. |

*系統升級采用U盤升級方式,方便簡單、實用,並提供終身免費升級服務。 Free upgrade by U-disk easily and conveniently, and also provide free-upgrade at whole lifetime. |

*特有鋼板校正功能,任意鋼板邊可做為校正邊; Steel board adjustment function,each steel edge could be adjustable. |

*圖形可矩陣排列、交互排列、疊式排列。 Graphic matrix permutation,alternate permutation,overlapping permutation |

*工件原始尺寸和帶割縫尺寸同時進行顯示,直觀方便。 Display original size and size with cutting slot compensation at sametime, easy to control conveniently. |

*等離子弧壓控制支持速度和距離兩種關閉弧壓調高方式,使機床更加平衡、安全。 Support speed and distance sytle to close THC,to ensure more balance,stable and safety. |

*最大程序行數The maximan lines of program. |

*預留等離子切割機電源接口,可選配各種等離子切割機機型,弧壓跟蹤系統以及初始定位裝置。 Plasma cutting machine interface reserved; optionally set up all types of plasma cutting machine and arc voltage tracking system, including initial position and automatic arc voltage tracking system. |

*選配:無線遙控器,可進行前、後、左、右等基本運作和切割開始、停止等切割動作。 Optional item: wireless controller, function: up,down,left,right,begin cutting or stop etc. |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。