數控塑料撕裂帶(打包繩)機組

CNC TYPE Lacerated Film-blowing Machine Unit (The Packing Line Making Machine)

編號(№):AC

產品介紹:

本設備是我公司新型開發的數控型塑料撕裂膜機組,采用數控同步倍頻控制系統,通過PLC通訊變頻控制器編程控制,在觸摸屏上對產品拉伸比例進行編程設定,整機采用全數控變頻控制器,PLC通訊控制,實時掌握機組運行狀況。設備具有結構簡單,操作方便,自動化程度高,連續生產效率高等優點。為我公司新型研發的塑料撕裂膜生產設備,屬同類產品領先技術。

主要用於以聚丙烯(PP)或再生塑料顆粒為原料,經配色,擠出,分切,牽引,加熱拉伸,定型,收卷等工序,支撐各種不同規格的塑料撕裂膜,捆紮繩,打包繩等日用軟包裝繩,產品具有輕薄柔軟,抗拉力強,耐酸堿性,色澤鮮艷等優點,是日用捆紮,紡織包裝,加捻制成各類股繩,裂膜線等捆紮繩類產品的優良材料。

特點:

1、 采用PLC數字化編程控制,自動化程度高,操作簡單,運行穩定。

2、 采用觸摸屏輸入,人機界麵對話界麵友好,實時監控設備運行狀態及各項數據。

3、 螺桿、料筒采用38CrMoAla材質,經氮化處理及精密加工,表層噴塗硬質合金,硬度高、耐磨、抗腐蝕。

4、 整機采用全自動變頻控制器,比常規產品節電大於30%

5、 滾筒式拉伸牽引機,PLC編程控制拉伸比例,同步倍頻操作,牽伸力度平穩,張力大。

6、整機采用高位剎車驅動,保證收卷整齊。

7、噪音低、無塵、環保節能。

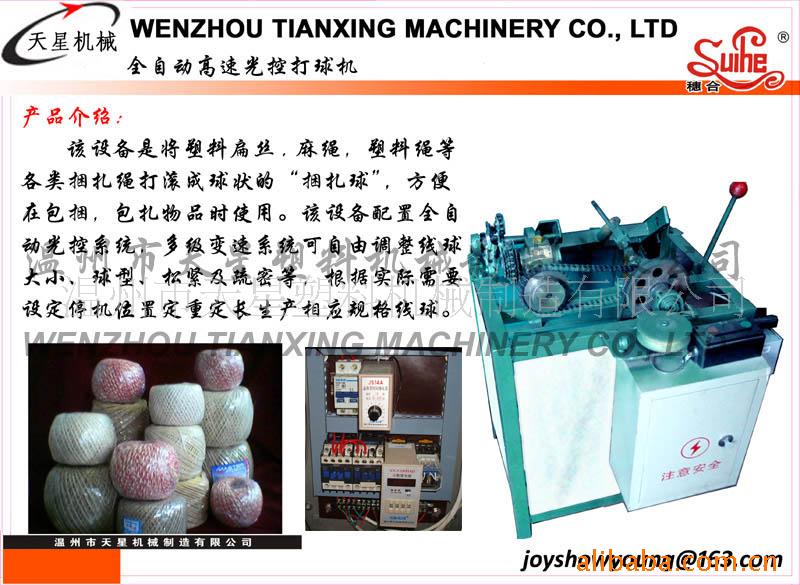

Introduce:

This machine uses polypropylene etc as raw material to make different colored flexible packaging rope of different specifications through color maching, extrusion, cutting, drawing, hot wire, winding and balling etc. Packaging rope has such features as softness, lightness, anti-pressing, acid-proof alkali, bright in color etc. It makes a good material for strapping goods, textile packaging and twisting different kinds of rope (cord).

This equipment has the following features: simple structure, safe operation, easier maintenance, high automaticity, good mechanical performance, continuous production.

Use:

This machine is used for making enlacing line and packing line. It can use to pack beer and other everyday use.

Characteristics:

1、 Using PLC digital programmed control, high degree of automation, simple operation, stable operation.

2、 Using the touch screen input, man-machine interface dialogue friendly interface, real-time monitoring the running state of the equipment and various data.

3、 Screw, barrel made of 38CrMoAla material, by nitrating treatment and precision machining, surface coating hard alloy, high hardness, wear resistance, corrosion resistance.

4、 The machine adopts automatic frequency controller node is greater than 30%, compared with the conventional product

5、 Roller type stretching machine, PLC programming control stretching ratio, synchronous frequency operation, stable drawing strength, tension.

6、 The whole set adopts perch brake driving. So the rewinding is very smooth.

7、 The noise is low, no dust, environmental and power saving.

主要技術參數Main Technical Parameters:

型號Type | AC65 | AC90 | AC105 | AC115 |

螺桿直徑Diameter of screw | Φ65mm | Φ90mm | Φ105mm | Φ115mm |

螺桿長徑比Length-diameter ratio of screw | 28:1 | 28:1 | 28:1 | 28:1 |

螺桿轉速Rotary speed of screw | 30-80 r/min | 20-60 r/min | 20-60 r/min | 20-60 r/min |

主機功率Motor power of extruder | 11kw | 15kw | 18.5kw | 22kw |

生產能力Production capacity | 20-30kg/h | 30-45kg/h | 40-60kg/h | 50-80kg/h |

主機加熱功率Heating power of extruder | 13kw | 15.5kw | 18kw | 23kw |

模頭口徑Diameter of handpiece mouth film | Φ300 | Φ300 | Φ400 | Φ450 |

吹塑最大折徑Max. flatwidth of film blowing | Φ600mm | Φ800mm | Φ1000mm | Φ1200mm |

牽引電機功率Power of driving motor | 1/2/2 | 1.5/2.2 | 2.2/3 | 3/4 |

牽引輥直徑Diameter of pull roll | Φ270mm | Φ270mm | Φ270mm | Φ270mm |

牽引線速度Line speed | 6-30 m/min | 6-30 m/min | 6-30 m/min | 6-30 m/min |

拉伸倍數Draft ratio | 1-5倍 | 1-5倍 | 1-5倍 | 1-5倍 |

拉伸控制方式Draft control mode | PLC | PLC | PLC | PLC |

成絲厚度Filament thickness | 0.015-0.07 | 0.015-0.07 | 0.015-0.07 | 0.015-0.07 |

烘箱寬度Width of heating plate | 700mm | 850mm | 1050mm | 1250mm |

烘箱加熱功率Heating power of the oven | 8kw | 12kw | 15kw | 17kw |

收卷Winding spindle | 12 | 16 | 20 | 24 |

整機安裝尺寸Installing Dimensions | 15200×1800×3150 | 18700×2200×3150 | 20700×2600×3150 | 22000×2800×3350 |

重量Weight | 2200kg | 2800kg | 3300kg | 3800kg |

註:以上產品外形或技術參數如有變化,恕不另行通知。Note:All technical parameter are subject to change without notice.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。