性能特征Performance feature

◎專用於法蘭式與對夾式蝶閥的壓力性能和閥瓣啟閉與電動裝置扭力試驗。

◎采用同步抱壓夾緊(分單式和組合套式)。

◎系統內配置高壓泵和大流量低壓水泵供壓裝置,試驗介質循環貯存使用。

◎試壓介質為水、氣、煤油,由用戶任意選擇。

◎設有試壓安全保護裝置。

◎可選配智能檢測數據管理系統。

◎It especially uses to flange and butt butterfly valve pressure performance and flap open & close and electric device torque test.

◎Adopt the synchronized contracting & pressing clamp (divide into single and combination)

◎Equip with the high and low pressure water pump pressure supply device in system, the test medium circulating storage use.

◎Pressure trial medium is water, air and kerosene, arbitrary option by users.

◎Equip with the pressure test safe protective device.

◎Order the matched intelligent detection data management system.

YDS-D型液壓蝶閥測試臺工作原理及使用方法

YDS-D type hydraulic butterfly valve test bench working principle and methods of use

YDS-D型蝶閥測試臺是專項適用於蝶閥性能試驗的檢測設備。本機集機、電、液和液動供壓裝置循環水系統於一體,工作臺夾緊爪采用油缸直接驅動夾緊蝶閥來實現測試,使各爪受力均勻,夾緊可靠、夾緊爪的徑向移動功能采用油缸、連桿組成,實現各爪徑向同步移動,保證瞭各大小不同通徑的蝶閥測試,測試密封時,如有帶法蘭的蝶閥夾緊法蘭、無法蘭的蝶閥由液壓夾爪直接伸延夾住蝶閥平麵即可測試。該機能直觀蝶閥內腔有否泄漏或冒氣泡,如試強度時加蓋上密封盲板即可,在該機上可做閥門電動裝置力矩及 90度開閉測試。該機隨帶液壓供水泵、介質可循環儲藏使用。使用清水時,必須加防銹劑,以免使閥門試後生銹及影響液動供壓裝置正常的使用功能。

使用方法:

一、用30#-40#液壓油或20#機械油註入液壓系統油箱內,油量不能低於油麵指示器下限。

二、接通電源,點動油泵起動按鈕,檢查電機旋轉方向是否正確(按順時針)。

三、將液壓系統壓力調至5.0MPa,即可以進行正常工作。

四、工作程序:

(1)點動夾爪退到最大位置;

(2)將被試蝶閥放在工作臺密封盤中心;

(3)點動夾爪小進至被測蝶閥所需位置;

(4)點動夾緊爪,夾緊被測蝶閥(法蘭或平麵);

(5)按增壓扭至所需壓力(夾緊油缸所需壓力對照表)(貼在機上)。增壓按鈕可多次點動,每次間隔若三秒鐘左右, (指第一次按下未達到所需壓力時)。最高壓力32MPa;

(6)進行水壓或氣壓對被試蝶閥進行測試;

(7)測試完 畢後,打開放水或氣開關,泄掉壓力即可;

(8)先後按各放松鈕,將被測閥門取下。

YCD-D type butterfly valve test bench is special suitable for butterfly valve performance test equipment. This machine set machine, electricity, liquid and hydraulic pressure supply device of circulating water system in one, working table clamping claw which directly drives the clamping cylinder valve to implement the test, so the claw of uniform stress, reliable clamping, clamping jaws radially moving function using the cylinder, connecting rod, the claw radial synchronous mobile, guarantee the size of each of the different butterfly valve test, test seal, such as a flanged butterfly valve, butterfly valve without clamping flange flange by a hydraulic clamping jaw clamp butterfly valve can be directly extended plane test. The function of intuitive butterfly valve cavity leakage or bubbles, such as strength with sealed blind plate, on the machine to do the electric device of the valve torque and 90 degree switch test. The machine with hydraulic pressure water supply pump, medium circulating storage using. The use of water, must be combined with anti-rust agent, so as to avoid the valve test after rust and effect of hydraulic pressure supply device normal use function.

Method of use:

one, use 30#-40# or 20# machinery hydraulic oil oil into the hydraulic system oil tank, oil can not be less than the lower limit of oil level indicator.

Two, the power supply is switched on, move the pump start button, check the motor rotation direction is correct ( clockwise ).

three, the hydraulic system pressure to 5.0MPa, that can work normally.

four, working procedure:

(1) move the jaw to the largest position;

(2) subjects butterfly valve on the workbench sealing disc center;

(3) to move the gripper into the small butterfly valve to be tested in the desired position;

(4) to move the clamping claw, the clamping measured butterfly valve ( flange or surface );

(5) according to the required pressure booster twist ( clamping cylinder pressure required to control table

(6) affixed to the machine ). Booster button repeatedly to move, if every three seconds or so, (the first time press did not reach the required pressure ). The maximum pressure of 32MPa; ( 6) by hydraulic pressure or air pressure on the valve test;

(7) testing is completed, open water or gas switch, release the pressure can;

(8) the button will successively according to relax, the tested valve removed.

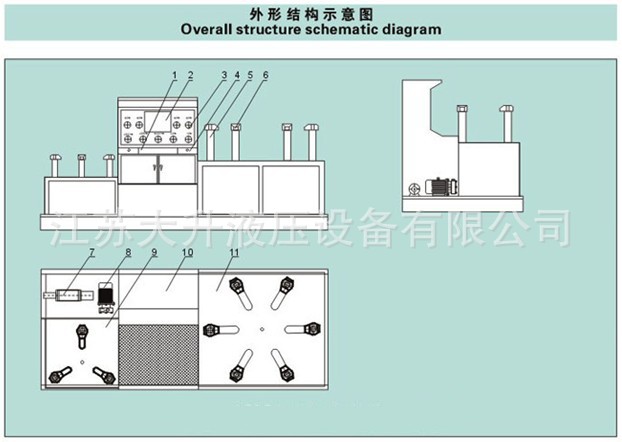

1 按鈕板 | 2 時鐘 |

3 壓力表 | 4 壓力表開關 |

5 壓緊活塞桿 | 6 壓爪 |

7 高壓水泵 | 8 低壓水泵 |

9 工作盤(小) | 10 液壓油箱 |

11 工作盤(大) |

|

YDS-D外型結構示意圖(套式)YDS-D Overall structure schematic diagram (set type | |

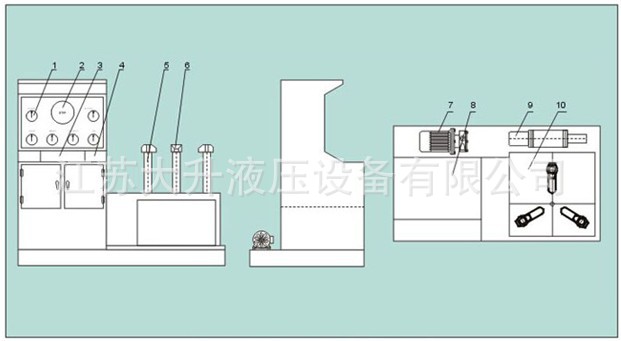

1 壓力表 | 3 按鈕板 | 5 活塞桿 | 7 低壓水泵 | 9 高壓水泵 | |

2 時鐘 | 4 壓力表開關 | 6 壓爪 | 8 液壓油箱 | 10 工作盤 | |

YDS-D外型結構示意圖(單式)YDS-D overall structure schematic diagram (single) | |||||

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。