| 種類:錫膏 | 材質:錫銀銅 | 產地:深圳 |

| 規格:3號粉,4號粉 | 用途:電子元器件焊接及貼片印刷 | 型號:Sn99Ag0.3Cn0.7 |

| 粘度:200(Pa·S) | 顆粒度:25-45(um) | |

ng>由於金屬價格行情波動較快,本店未能及時更正價格,所以各位買傢購買產品之前請先旺旺咨詢或者直接電話咨詢,以免購買產品後產生不必要的紛爭,不便之處,敬請諒解,謝謝合作,祝購物愉快!! ng>

ng>

ng>

ng>1.保存方法ng>

ng>錫膏的保管要控制在1-10℃的環境下;錫膏的使用期限為6個月(未開封);不可放置於陽光照射處。ng>

ng>2.使用方法(開封前)ng>

ng>開封前須將錫膏溫度回升到使用環境溫度上(25±2℃),回溫時間約3-4小時,並禁止使用其他加熱器使其溫度瞬間上升的做法;回溫後須充分攪拌,使用攪拌機的攪拌時間為1-3分鐘,視攪拌機機種而定。ng>

ng>3.使用方法(開封後)ng>

ng>1)將錫膏約2/3的量添加於鋼網上,盡量保持以不超過1罐的量於鋼網上。ng>

ng>2)視生產速度,以少量多次的添加方式補足鋼網上的錫膏量,以維持錫膏的品質。ng>

ng>3)當天為使用完的錫膏,不可與尚未使用的錫膏共同放置,應另外存放在別的容器之中。錫膏開封後在室溫下建議24小時內用完。ng>

ng>4)隔天使用時應先行使用新開封的錫膏,並將前一天未使用完的錫膏與新錫膏以1:2的比例攪拌混合,並以少量多次的方式添加使用。ng>

ng>5)錫膏印刷在基板後,建議於4-6小時內放置零件進入回焊爐完成著裝。ng>

ng>6)換線超過1小時以上,請於換線前將錫膏從鋼板上刮起收入錫膏罐內封蓋。ng>

ng>7)錫膏連續印刷24小時後,由於空氣粉塵等污染,為確保產品品質,請按照“步驟4)”的方法。ng>

ng>8)為確保印刷品質建議每4小時將鋼板雙麵的開口以人工方式進行擦拭。ng>

ng>9)室內溫度請控制與22-28℃,濕度RH30-60%為最好的作業環境。ng>

ng>10)欲擦拭印刷錯誤的基板,建議使用工業酒精或工業清洗劑ng>

ng>

ng>

ng>操作說明 APPL ICATIon NOTES ng> |

ng>用途ng> |

ng>9037系列適用於Sn99/Ag0.3/Cu0.7無鉛焊料合金.推薦採用3號金粉,但根據不同的用塗如標準ng> |

ng>印刷和超細間距選用不同的IPC合金末類型。ng> |

ng>印刷參數ng> |

ng>印刷刮刀ng> | ng>80-90肖氏硬度的聚亞安酯或不銹鋼材料ng> |

ng>刮刀速度ng> | ng>25-150mm/secng> |

ng>磨板材料 ng> | ng>不銹鋼|、鉬、或黃銅ng> |

ng>溫度濕度ng> | ng>溫度70-77F(21-25℃)、濕度35-65% R.H.ng> |

ng> ng> |

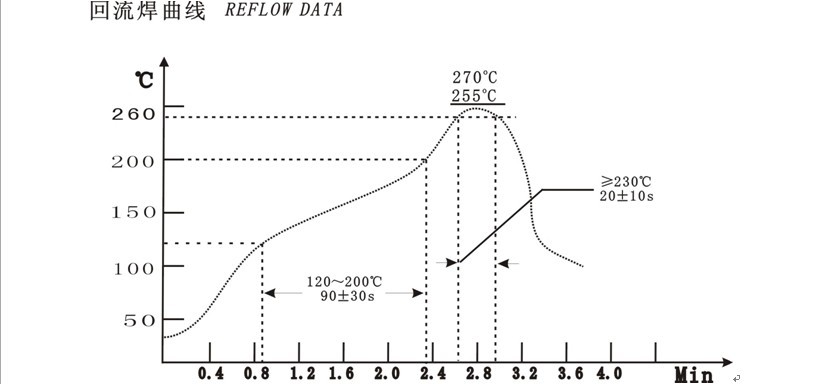

ng>回流焊曲線REFLOW DATAng> |

ng> ng> ng>

ng> ng> |

ng>升溫速率ng> | ng>到達120℃所需時間ng> | ng>預熱120-200℃ng> | ng>峰值溫度ng> | ng>>230℃ng> | ng>冷卻速度ng> | ng> ng> |

ng>1~3℃/S MAXng> | ng>〈90秒ng> | ng>90±30秒ng> | ng>>260℃ng> | ng>20±10秒ng> | ng><4℃/Sng> | ng> ng> |

ng>焊後清洗ng> |

ng>9037系列屬於免洗錫膏。一般應用時無需清洗焊後殘留物。ng> ng>如需進行清洗,9037系列焊後殘留物也很容易借助保奇相對應的清洗劑清洗。ng> |

ng>包裝形式 ng> | ng>瓶裝 --每瓶250克和500克可供選擇ng> |

ng>貯存、操作及保存期限ng> |

ng>9037在5-10℃條件下可保存6個月。註意不要對錫膏進行冷凍處理。ng> ng>錫膏打開包裝使用前需進行充分回溫到室溫(推薦4個小時)ng> ng>冷藏保存時可能會引起錫膏內組分的分離,使用前充分攪拌錫膏1-5分鐘以充分混合均勻。ng> ng>不要將用剩的錫膏與新的錫膏混合在同一包裝內。錫膏不需要使用時應重新進行密封,當瓶蓋不能很好地進行密封保存時請更換瓶蓋內襯以保證盡可能的密封。ng> |

ng>9037免洗錫膏合金成份表(Sn99/Ag0.3/Cu0.7)ng> |

ng>成分ng> | ng>Snng> | ng>Pbng> | ng>Cung> | ng>Cdng> | ng>Znng> | ng>AIng> | ng>Sbng> | ng>Feng> | ng>Asng> | ng>Agng> | ng>Ning> |

ng>含量ng> | ng>Remng> | ng>≤0.08ng> | ng>0.7ng> | ng>≤0.002ng> | ng>≤0.002ng> | ng>≤0.01ng> | ng>≤0.12ng> | ng>≤0.02ng> | ng>≤0.006ng> | ng>0.3-.045ng> | ng>≤0.005ng> |

ng> ng> |

ng>測試報告ng> |

ng>型號:9037ng> |

ng>助焊劑類型:ROMOng> |

ng>原始資料測試日期:12/04/2009ng> |

ng> ng> |

ng>測試項麼目ng> | ng>依據細則ng> | ng>IPC-TM-650測試方法ng> | ng>測試要求ng> | ng>測試結果ng> |

ng>金屬含量ng> | ng>3.4ng> | ng>2.2.20ng> | ng>89.5-90.5%ng> | ng>89.7%ng> |

ng>黏度ng> | ng>3.5ng> | ng>BrookfieIdng> | ng> ng> | ng>700-1400kcpsng> | ng>700-1100ng> |

ng>MaIcomng> | ng> ng> | ng>150-250kcpsng> | ng>170-230ng> |

ng> ng> | ng>3.6ng> | ng> ng> | ng>無橋聯ng> | ng>合格ng> |

ng>錫球ng> | ng>3.7ng> | ng>2.4.43ng> | ng>無成簇或大錫球ng> | ng>合格ng> |

ng>擴展率ng> | ng> ng> | ng>4.7.7.2.2ng> | ng> ng> | ng>92%ng> |

ng>銅鏡測試ng> | ng>3.2.4.1ng> | ng>2.3.32ng> | ng><50%穿透ng> | ng>合格ng> |

ng>鹵素測試ng> | ng>3.2.4.2ng> | ng> ng> | ng> ng> | ng> ng> |

ng>鉻酸銀試紙測試ng> | ng>3.2.4.2.1ng> | ng>2.3.33ng> | ng>無顏色改變ng> | ng>合格ng> |

ng>氟點測試ng> | ng>3.2.4.2.2ng> | ng>2.3.35.1ng> | ng>無顏色改變ng> | ng>合格ng> |

ng>銅麵腐蝕ng> | ng>3.2.4.4ng> | ng>2.6.15ng> | ng>輕微腐蝕可接受ng> | ng>合格ng> |

ng>表麵絕緣阻抗ng> | ng>3.2.4.4ng> | ng>2.6.3.3ng> | ng>0小時ng> | ng>>1.00×108ng> | ng>1.09×1012ng> |

ng>3.2.4.5ng> | ng>96小時ng> | ng>>1.00×108ng> | ng>1.38×1011ng> |

ng>特徵 FEATURUSng> |

ng>無鉛焊料ng> | ng>12小時連續印刷能力ng> |

ng>6小時塌時間表ng> | ng>無需要氣保護ng> |

ng>黏度持續保持不變ng> | ng>16miI(0.4mm)簡距的可印刷性ng> |

ng>焊膏成分 STANDARD PASTE COMPOSTIonng> |

ng>應用特徵ng> | ng>IPC合金類型ng> | ng>合金粉尺寸ng> | ng>合金粉含量ng> |

ng>標準印刷ng> | ng>3ng> | ng>25-45umng> | ng>89%ng> |

ng>細間距印刷ng> | ng>4ng> | ng>20-38umng> | ng>88.5%ng> |

ng>滴註ng> | ng>3ng> | ng>25-45umng> | ng>85%ng> |

ng>物理性能 PHYSICAL PROPERTIESng> |

ng>適於89%,-325+500目合金粉焊錫膏ng> |

ng>BrookfieId:700-1400kcPs @ 5 RPM(BrookfieId Viscmter at25℃)ng> |

ng>MaIcom:1700-2300 Poise @ 10 RPM(MaIcom Viscometer at25℃)ng> |

ng>錫球測試ng> | ng>合格ng> | ng>測試標準ng> | ng>J-STD-005,IPC-TM-650,Method 2. 4. 43ng> |

ng>濕潤性測試ng> | ng>合格ng> | ng>測試標準ng> | ng>J-STD-005,IPC-TM-650,Method 2. 4.45ng> |

ng>可靠性能 REL IABILTY PROPERTIESng> |

ng>銅鏡測試ng> | ng>合格(低)ng> | ng>測試標準ng> | ng>J-STD-004,IPC-TM-650,Method 2. 3. 32.ng> |

ng>銅麵腐蝕測試ng> | ng>合格(低)ng> | ng>測試標準ng> | ng>J-STD-004,IPC-TM-650,Method 2. 6. 15ng> |

ng>鹵素含量測試ng> |

ng>鉻酸銀試紙測試ng> | ng>合格ng> | ng>測試標準ng> | ng>J-STD-004,IPC-TM-650,Method 2. 3. 33ng> |

ng>氟點測試ng> | ng>合格ng> | ng>測試標準ng> | ng>J-STD-004,IPC-TM-650, Method 2. 3. 35. 1ng> |

ng>表麵絕緣阻抗ng> | ng>合格ng> | ng>測試標準ng> | ng>J-STD-004,IPC-TM-650,Method 2. 6. 3. 3ng> |

ng>由於錫屬於金屬類的貴重物品,因國內外很多不定因素影響,每天行情波動較大,本店的價格也會隨著行情的波動進行調整,請您在購買時多多與客服溝通,多多比較!謝謝合作!本店不支持7天無理由退換貨,不得以價格變動為理由要求賠償及退貨。以當天旺旺確認後拍下的價格為準。不接受多退少補!ng>

ng>快遞說明:默認快遞為中通,圓通,廣東省內代收貨款默認信豐快遞,物流(平郵)到達需3-7天,到瞭當地需自取。註:由於我們的貨物比較貴重,每件發往外省的貨物,我們都購買瞭保險,若不檢查就簽收,過後所有損失物流公司將不負責。請親們在簽收之前務必要打開,清點好貨物無誤後再簽收。以免造成不必要的損失!ng>

ng> ng>

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。