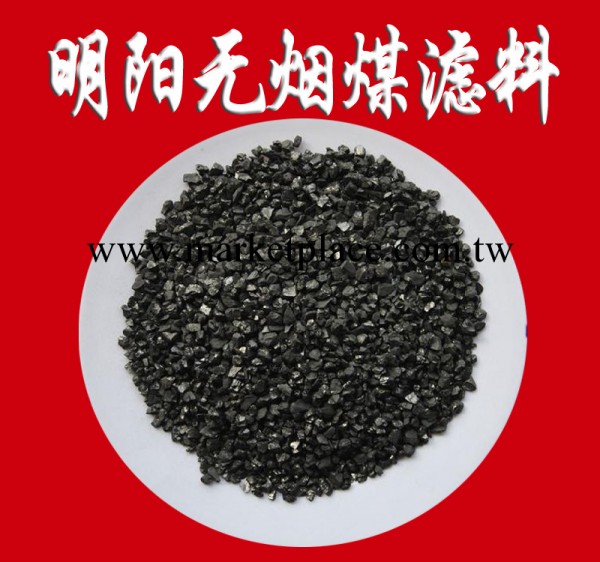

| 濾料類型:無煙煤 | 適用對象:水 | 用途:水過濾 |

| 性能:耐酸,耐堿,耐高溫,防火,防水,防靜電 | 類型:高效 | 品牌:明陽 |

| 吸附率:98(%) | 抗壓力:600(kgf) | 密度:1.5(g/cm3) |

| 孔隙率:50(%) | 磨損率:0.47 | 硬度:3.15 |

| 化學成分:C | 鹽酸可溶率:1(%) | C:80% |

| 灰份:3-5% | S:0.05% |

無煙煤濾料是目前普遍采用的最佳過濾材料,同石英砂濾料配合使用是我國目前推廣的雙層快速濾池和三層濾池、濾罐過濾的常見形式。是提高濾速增加單位麵積出水量和成倍提高截污能力,降低工程造價和減少占地麵積最有效的途徑。廣泛應用於化工、冶金、熱電、制藥、造紙、印染、食品等的生產前後的水質處理過程中。

無煙煤濾料是一種水處理行業過濾用濾料。

無煙煤濾料是采用優質無煙煤為原料,經精選碎,粉,篩等工藝

無煙煤濾料在過濾過程中所起作用的好壞,直接影響著濾過的水質,故對此

1、機械強度高,破碎率和磨損率之和不應大於3%(按重量計)。

2、化學性能穩定,不含有毒有害物質。在一般酸性、堿性、中性水中均不溶解。我廠產品經中國水處理濾料監督檢測中心測定:鹽酸可溶率為0.98%(部頒標準為3.5)在各類水源中均可達到良好的凈化效果。

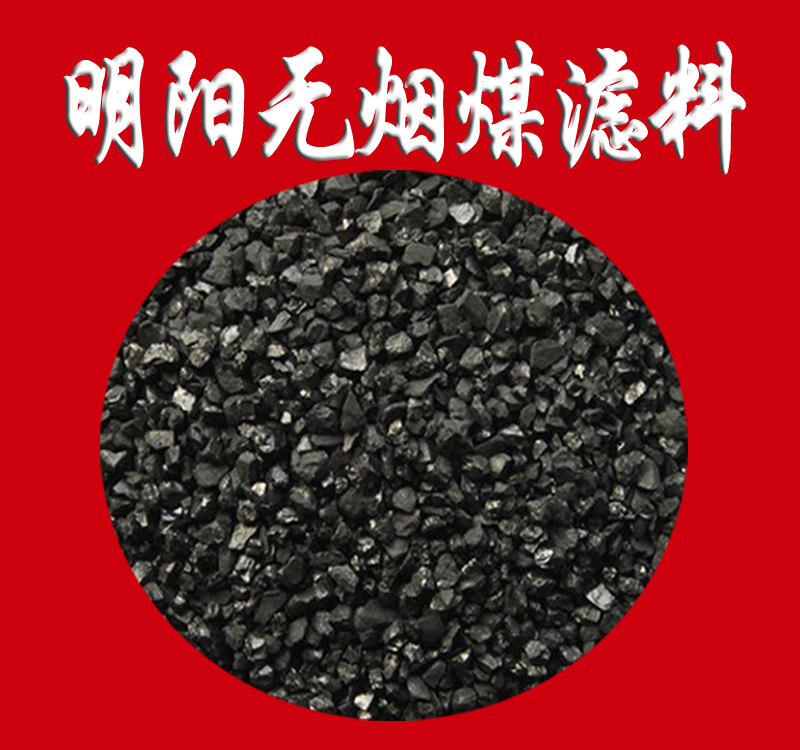

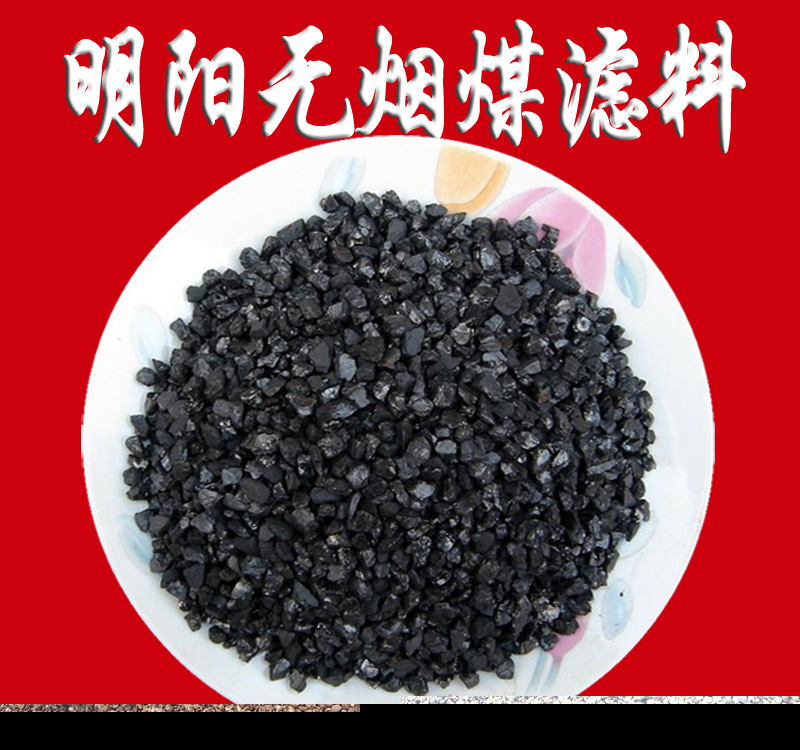

3、粒徑級配合理,比表麵積好。產品外觀呈球狀而有棱角,光澤度好,經機械振動三次篩分,級配符合有關技術指標。

4、粒徑范圍小於指定下限粒徑按重量計不大於3%,大於指定上限粒徑按重量計不大於2%。

1、濾料在填充前必須將濾池(濾器)內部清掃乾凈。

2、要均勻地鋪設每層濾料,當達到標定厚度時,必須耙平濾料。

3、濾料長期運行,會有磨損。如操作不當會有“跑料”發生。為此需定期檢查濾料狀況,如有虧料情況,需及時補充。如濾料運行時間過長,出水水質長期不清,或濾層發生亂層,則需更換或重新級配濾料。

加工而成是普遍采用雙層,三層快速過濾材料。實用於一般酸性,中性堿性的凈化處理,具有良好的比表麵積,各項指標均達到建設部(CJ/T44-1999)標準。無煙煤濾料是特別從深井礦物中精選的,具有最高的含碳量百分比。

無煙煤濾料采用人工分類,可減少無關礦物質並降低灰分含量。還經過過濾和沖洗,確保其適合水過濾之用。 由於具有較好的固體顆粒保持能力,因此無煙煤能夠可靠地提高懸浮顆粒清除能力。 此外,它的均勻系數較低,有助於加快流速。

分析項目 | 鑒定數據 | 分析項目 | 鑒定數據 | 分析項目 | 鑒定數據 |

比重 | 1.57 | 大於1.8g/cm3物質 | ≤3% | S含量 | 0.05% |

容重 | 0.947t/m3 | 鹽酸可溶率 | 0.98% | Pb含量 | 0.045% |

破碎率 | ≤0.68% | 孔隙率 | 51.99% | Cu含量 | 0.025% |

磨損率 | ≤0.32% | 均勻系數 | K60≤2.0 | Zn含量 | 0.04% |

灰粉 | ≤1.0% | 不均勻系數 | K80≤1.5 | 燃燒值 | 6800Kee/kg |

密度 | 1.57g/cm3 | 含泥量 | ≤0.52 | 其它重金屬含量 | 不超過國傢飲用水標準 |

固有水分 | ≤1% | C含量 | ≤90% |

1、無煙煤濾料的破碎率和磨損率之和不應大於3%(百分率按質量計,下同)。

2、無煙煤濾料的平均密度一般不小於1.4g/cm3,不大於1.6g/cm3。

3、無煙煤濾料應不含可見泥土、頁巖和外來碎屑。含泥量不應大於3%,密度大於

1.8g/cm3的物質含量不應大於8%。

4、無煙煤濾料的鹽酸可溶率不應大於3.5%。

1、用於生活飲用水的無煙煤的粒徑范圍為:0.8-1.2mm、1.2-2mm;工業用水無煙煤的粒徑范圍為:1-2mm、2-4mm、4-6mm。

2、在各種粒徑范圍的無煙煤中,小於指定下限粒徑的不應大於3%,大於指定上限粒徑的不應大於2%。

Anthracite filter material product description

Anthracite filter material is widely used at present the best filtration material, with quartz sand filter material used in conjunction with China is the promotion of double rapid filter and three layer filter, filter can filter the common form. Is to improve the filter speed increase unit area water yield and doubled section carrying capacity, reduce the project cost and reduce covers an area of the most effective way. Widely used in chemical industry, metallurgy, thermoelectric, pharmaceutical, paper making, printing and dyeing, food and so on production before and after the water treatment process.

Anthracite filter material product details

Anthracite filter material is a kind of water treatment industry for filter filter material.

Anthracite filter material is produced with high quality anthracite coal as raw material, the selected broken, powder, screen technology

Anthracite filter material in the filtering process action is good or bad, a direct impact on the filtered water quality, so the choice of this filter material must meet the following requirements:

1, high mechanical strength, the broken rate and the wear rate of the should be greater than 3% (by weight meter).

2, stable chemical performance, does not contain the poisonous and harmful material. In the general acid, alkaline and neutral water are insoluble. Our products has been approved by the China water treatment filter material supervision and inspection center determination: hydrochloric acid soluble rate was 0.98% (ministerial standard for 3.5) in all kinds of water source may achieve good cleaning effect.

3, particle size distribution is reasonable, specific surface area is good. Product appearance spherical and angular, good gloss, the mechanical vibration three screening, grading comply with the relevant technical indicators.

4, particle size range is less than the specified limit size weight meter is not more than 3%, more than the maximum limit specified size weight meter is not more than 2%.

Anthracite filter material filling the matters needing attention and operational requirements

1, filter material must be filled in before the filter (filter) internal clean.

2, to evenly laid each layer filter material, when to calibration thickness, must rake flat filter material.

3, filter material for the long term operation, there will be wear. Such as improper operation will have "run material" occurred. Therefore need to regular inspection filter material status, if there is a deficit, material should be added in time. Such as filter material running time is too long, outlet water quality long-term not clear, or filter happen disorderly layer, the need to change or to grading filter material.

Processing and to be widely adopted double, three layer rapid filtration material. Practical in the general acid, neutral alkali purification treatment, has the good specific surface area, and all the indexes to the ministry of construction (CJ/T44-1999 standard. Anthracite filter material is special in minerals from a deep well selected, with the highest percentage of carbon content.

Anthracite filter material using artificial classification, can reduce independent minerals and reduce ash content. Also after filtering and washing, ensure its suitable for the use of water filtration. Because of its good solid keep ability, therefore anthracite can be reliably improve suspended particle removal ability. In addition, its uniformity coefficient is low, help to speed up the flow velocity.

Anthracite filter food chemical index

Analyze project appraisal data analysis project appraisal data analysis project appraisal data

Specific gravity 1.57 more than 1.8 g/cm3 material or less 3% S 0.05% content

Bulk density of 0.947 t/m3 hydrochloric acid soluble rate 0.98% Pb content 0.045%

Broken rate 0.68% or less porosity 51.99% Cu content 0.025%

Wear rate 0.32% or less uniformity coefficient K60 acuities were 2.0 0.04% Zn content

Ash powder 1.0% or less uneven coefficient K80 acuities were 1.5 combustion value 6800 kee/kg

Density 1.57 g/cm3 silt content acuities were 0.52 other heavy metal content is more than the national standards for drinking water

Inherent moisture content 90% or less 1% C or less

A, the anthracite filter material】commonly known as "stone coal", it is the deepest degree of coalification coal. Is a kind of water treatment industry filter materials. Ningxia MingYang activated carbon co., LTD. Is the production of anthracite filter material (standards: People's Republic of China urban construction industry standards (CJ/T43-2005) is to choose the high quality anthracite coal as raw materials. The crushing, screening, washing and processed. Features are: fixed carbon content is high, the density, strength, appearance luster, stable chemical performance, has good solid keep ability, can reliable improve suspended particle removal. Does not contain poisonous and harmful material. In acid, neutral water are insoluble. Compression wear resistance is strong, have plenty of specific surface area and reasonable particle size distribution. Because of its good solid keep ability, so it can improve the reliability of the suspended particle removal ability. It is suitable for drinking water and industrial water filtration.

Second, the anthracite filter material technical requirements

1, anthracite filter material crushing rate and the wear rate of the should be greater than 3% (percentage in accordance with the quality plan, the same below).

2, anthracite filter material, the average density generally not less than 1.4 g/cm3, not more than 1.6 g/cm3.

3, anthracite filter material should not contain visible mud, shale and foreign debris. Silt content should not be greater than 3%, density is more than

1.8 g/cm3 material content should not be greater than 8%.

4, anthracite filter material hydrochloric acid soluble rate should not be greater than 3.5%.

Third, the anthracite filter material】size

1, used for drinking water of anthracite range of particle size is: 0.8 1.2 mm, 1.2 2 mm; Industrial water anthracite particle size range for: 1-2 mm, 2-4 mm, 4-6 mm.

2, in various sizes of anthracite, less than the specified limit size should not be greater than 3%, more than the specified limit size should not be greater than 2%.

Packing: 25 kg woven bag packing, the lining plastic, packaging printing can provide material.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。