| 濾料類型:果殼 | 適用對象:水 | 用途:水過濾 |

| 性能:耐酸,耐堿,其他 | 類型:高效 | 品牌:恒星 |

| 吸附率:85(%) | 抗壓力:100(kgf) | 密度:1.5(g/cm3) |

| 孔隙率:0.38(%) | 磨損率:3.46 | 硬度:7.8 |

| 化學成分:核桃殼 | 鹽酸可溶率:0.38(%) | |

ng>核 桃 殼 磨 料ng> |

ng>

核桃殼濾料采用優質山核桃殼為原料,經過破碎、拋光、蒸洗、藥物防腐處理,兩次篩選加工而成。此濾料堅韌、耐磨、抗壓(抗壓力為23.4kgf),化學性能穩定,吸附截污性強(吸附率為27-50%),抗油浸,易反洗再生,反沖洗強度低(6.7L/Sm2),濾速快(24-26m/h),不板結,不腐爛,永不更換,每年隻需補充5-10%即可。油去除率達95%,含油降至5mg/g以下。適用於油田、節油環保設備等方麵。ng> |

ng> ng> ng>檢測項目ng> | ng> ng> ng>測試數據ng> | ng> ng> ng>檢測項目ng> | ng> ng> ng>測試ng> | ng>油去除率ng> | ng>90-95%ng> | ng>反洗強度ng> | ng>25m3/m2.hng> | ng>懸浮物去除率ng> | ng>95-98%ng> | ng>水沖洗壓力ng> | ng>0.32MPang> | ng>濾 速ng> | ng>20-25m/hng> | ng>維護方式ng> | ng>每年補充5-10%ng> | ng>比 重ng> | ng>1.5g/cm3ng> | ng>堆 密 度ng> | ng>0.8g/cm3ng> |

|

ng>廠傢直供核桃殼!專業的核桃殼生產廠商!ng>

ng>核桃殼(核桃殼濾料 生產核桃殼 核桃殼顆粒 核桃殼工藝品 噴砂核桃殼)ng>

ng> ng>

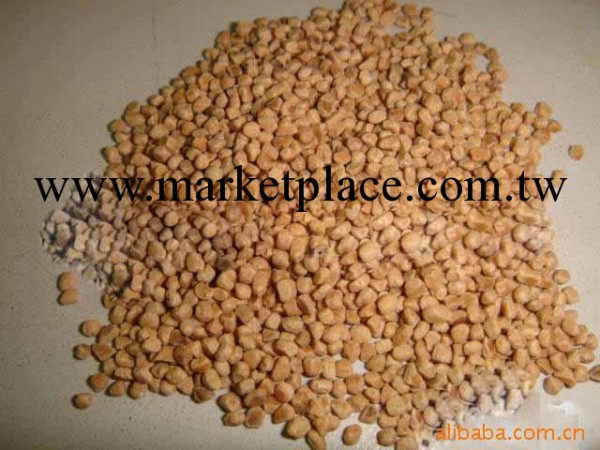

ng>一、[成孔材料]核桃殼粒 ng>

ng>

本廠采用國外先進的工藝、技術,專業生產陶瓷結合劑氣孔砂輪成孔材料--核桃殼粒。該產品與以往的成孔材料--精萘相比,具有氣孔均勻、

無氣味、無污染,使用方便,價格便宜,對使用員工的身體無損還,安全。而且,對砂輪氣孔大小可以任意選擇。因此,在國外60年代磨

料磨具行業中已被廣泛采用。 ng>

ng> 理化性能指標 ng>

ng>堆積密度:16#--36# 0.85±0.05g/cmng>

ng>46#--80# 0.80±0.05g/cmng>

ng>粒 度:16#--36# 16#篩上物為0,36#篩下物≤4%ng>

ng>46#--80# 46#篩上物為0,80#篩下物≤2%ng>

ng>色 澤:黃棕色顆粒ng>

ng>產品規格:8#、10#、12#、14#、16#、20#、24#、30#、36#、46#、60#、80#、100#、120#ng>

ng>另外規格可按使用企業需求制作ng>

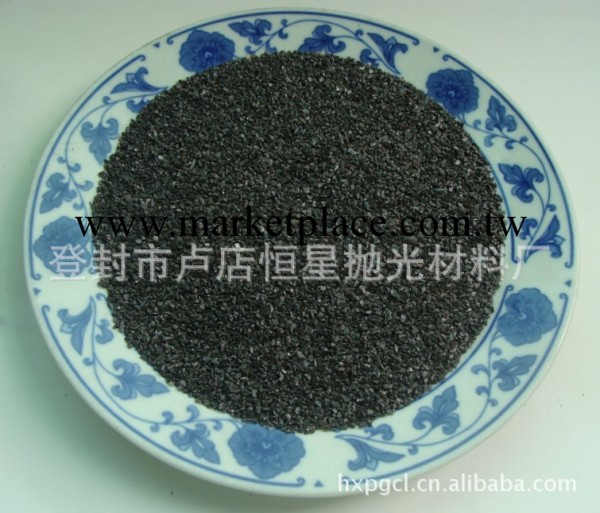

ng>二、[拋光材料]核桃殼ng>

ng>經特殊工藝加工而成的該類拋光材料,具有優良的耐磨性能,均勻的粒度,特高的殼含量。ng>

ng>理化性能指標ng>

ng>比 重:1.28 硬 度:2.5—3.0MOH 酸 度:3—6PHng>

ng>殼含量:90.90% 仁含量:0.4% 水份含量:8.7%ng>

ng>產品規格ng>

ng>5#5.00—4.00mm, 6#4.00—3.15mm, 8#2.80—2.36mm, 10# 2.00—1.80mmng>

ng>12# 1.70—2.50mm, 14# 1.40—1.25mm, 16# 1.18—1.06mm, 20# 0.95—0.85mmng>

ng>24#0.800—0.630mm, 30#0.600—0.560mm, 36#0.530—0.450mmng>

ng>46#0.425—0.355mm, 60#0.315—0.250mm, 80#0.212—0.180mmng>

ng>100# 0.170—0.132mm, 120# 0.125—0.100mmng>

ng>三、[濾料]核桃殼ng>

ng>外觀:光澤優美、呈褐色,采用優質山核桃殼為原料,經破碎、風旋、拋光、蒸洗、篩選等加工而成ng>

ng>特點:此濾料堅韌性大,耐磨抗壓、吸附能力強、抗油浸、不結塊、不腐爛ng>

ng>用途:它是多用於油田、冶煉、環保化工等行業含油污水處理的理想過濾材料理化性能指標ng>

ng>比重:1250kg/cm3 容重: 800kg/cm3 磨損率:≤1.5%ng>

ng>浮皮率:3% 孔隙率:47 除油率:65-95%ng>

ng> ng>

ng> ng>

ng>常用規格:0.5-1.0mm 0.5-0.8mm 0.6-1.2mm 0.8-1.6mm 1.0-2.0mmng>

ng> ng>

ng>一. [pore-forming materials] walnut shell particlesng>

ng>Our factory using foreign advanced technology specialized in vitrified bond grinding wheel hole porosity materials - walnut shell grains. Compared with the old pore-forming material-- refined naphthalene, our product has uniform pores, and it is odorless, non-polluting, easy to use, inexpensive and safe. Moreover, the pore size of the grinding wheel can be arbitrarily selected. Thus, in 60 years abroad, it has been widely adopted in abrasives industry.

Physical and chemical performance index

Bulk Density: 16 # - 36 # 0.85 ± 0.05g/cm

46 # - 80 # 0.80 ± 0.05g/cm

Size: 16 # - 36 # ,the screen overflow of 16# is 0, the screen underflow of 36# is no more than4%ng>

ng>46 # - 80 #, the screen overflow of 46# is 0, the screen underflow of 80# is no more than2%ng>

ng>Color: Yellow-brown granules

Product Specification: 8 #, 10 #, 12 #, 14 #, 16 #, 20 #, 24 #, 30 #, 36 #, 46 #, 60 #, 80 #, 100 #, 120 #ng>

ng>Specifications can be produced as needed.ng>

ng>二. [Polishing Material] walnut shellng>

ng>Such polishing materials processed by the special process have excellent wear resistance, uniform particle size, and ultra-high shell content.ng>

ng>Physical and chemical performance index

Specific Gravity: 1.28 Hardness: 2.5-3 .0 MOH Acidity: 3-6PH

Shell content: 90.90% kernel content: 0.4% Moisture content: 8.7%ng>

ng>Specifications

5 # 5.00-4.00mm, 6 # 4.00-3.15mm, 8 # 2.80-2.36mm, 10 # 2.00-1.80mm

12 # 1.70-2.50mm, 14 # 1.40-1.25mm, 16 # 1.18-1.06mm, 20 # 0.95-0.85mm

24 # 0.800-0.630mm, 30 # 0.600-0.560mm, 36 # 0.530-0.450mm

46 # 0.425-0.355mm, 60 # 0.315-0.250mm, 80 # 0.212-0.180mm

100 # 0.170-0.132mm, 120 # 0.125-0.100mmng>

ng>三. [Filter] walnut shellng>

ng>Appearance:shiny ,beautiful, brown. High-quality fruit (coconut, apricot) shell as raw materials, it is refined handled and screening made by water vapor activation crumbs.ng>

ng>Features: developed gap, good adsorption properties, high strength, easy regeneration, economic and durable and so on.

Uses: It is used for oil field, refining, environmental protection, chemical industry wastewater treatment and so on.ng>

ng>Physical and chemical performance index

Weight: 1250kg/cm3 bulk density: 800kg/cm3 wear rate: ≤ 1.5%

Puffiness rate: 3% porosity: 47 degreasing rate: 65-95%

Common Specifications: 0.5-1 .0 mm 0.5-0.8mm 0.6-1.2mm 0.8-1.6mm 1.0-2.0mm 2.0-4.0mmng>

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。