????

??????????????????????????????????????????????????

????????

Pro/E,Auto CAD,Solid work,UG,CAD

????????

????????→????????→????????→CNC????→ ????????→????????→????

????????????

????????????????????????????????????????????????????

????

???????????????????????????????????????????????? ??????????????

????

ISO9000,ISO9001

????????????????about DE card quality concept ?????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????? We put the quality of the product in the first, put the quality as the survival foundation, we are working around the quality. Our way is: the quality of standardized operation, quality assurance, continuous improvement, customer satisfaction.

????????Quality control: ????????????????????????????????????????????????????????????????????????????2.0+L??300um,??????????X=500mm,Y=500mm,Z=500mm.????????????????????????????????--?????????????????? To ensure quality control, we purchase the german-made three coordinate measuring machine (three dimensional), its measurement precision is 2.0 + L, 300 um, the measuring range is X = 500 mm, Y = 500 mm, Z = 500 mm. This measuring machine is very suitable for measuring small parts, precision made visible to the naked eye.

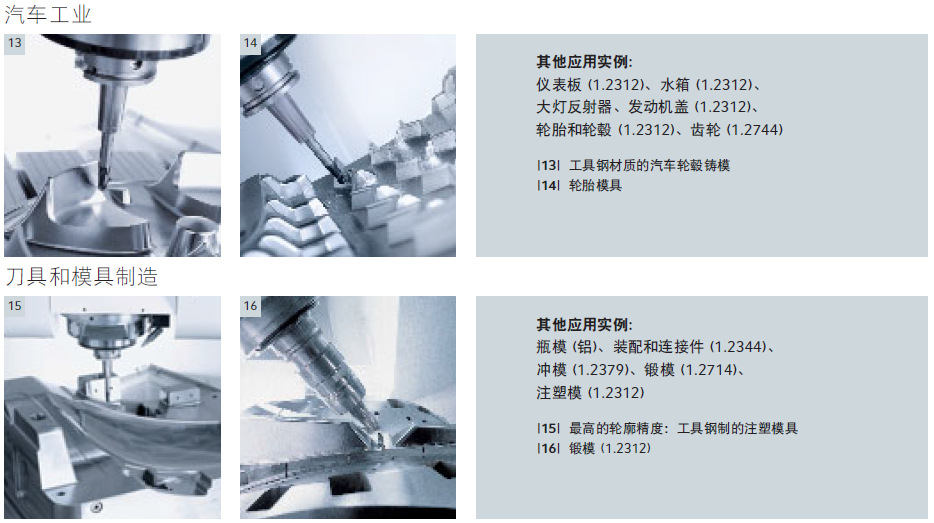

??????????Our team?? ?????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????? ????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????ODM?? ????????????????????????????????????????????????????????????HRC62??????????????????????????????lnconel????????????????????????????X,X,Z??????????????????????????±0.005mm,????????????????????????±0.02mm. ??????????????????????????????????????????????????????????????????±0.01mm????????????????????????????????±0.002??????????±0.005????????????????????????????????????????????????????

Our engineers skilled in modern processing technology, for a variety of three axis, four axis and 5 axis machining programming methods have a lot of experience and can meet the customer's design and manufacture of complex workpiece, finally can meet the requirements of the customers' increasingly rich, for clients to achieve their goals provide the precision of the system components.

Our site personnel with three years of professional education, and have a good training, make them more at the time of customer service! Our engineers use modern design software and familiar with the requirements of the automation system, providing customers with automation components and systems of the original design, help customers to achieve the overall automation equipment design goal. Also can undertake engineering design in accordance with the requirements of the customers, for customers to solve the various problems in project development, and also is the ODM.

Our team has rich experience to processing a variety of materials, from aluminum alloy, copper to hardness up to HRC62 mould materials and titanium alloy, high temperature alloy lnconel, etc. Made in Germany in the five axis machining center, X, X, Z driven by linear motor, can achieve + / - 0.005 mm, of five-axis machining condition can be + / - 0.02 mm.

Made in Germany four axis machining center and turning center. For four axis machining parts, we can achieve the tolerance + / - 0.01 mm, for turning parts, we can achieve the roundness of 0.002 mm and 0.005 mm demanding tolerance, high precision of measuring machine is the ultimate guarantee of product processing results.

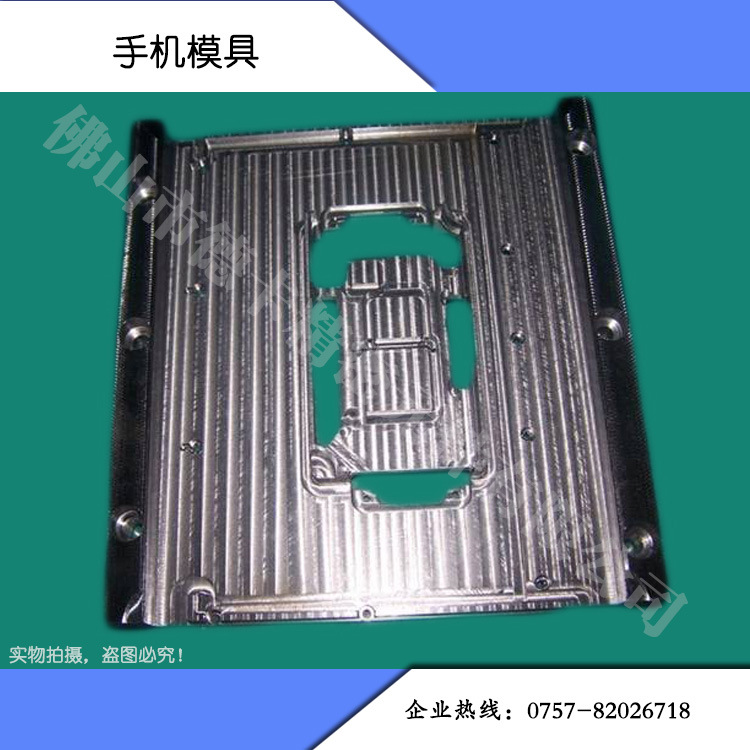

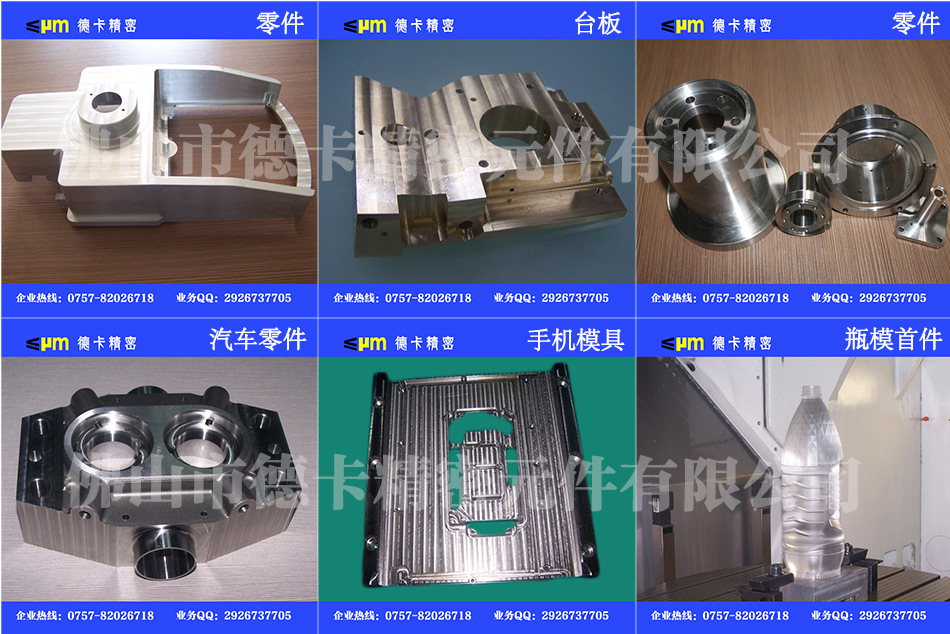

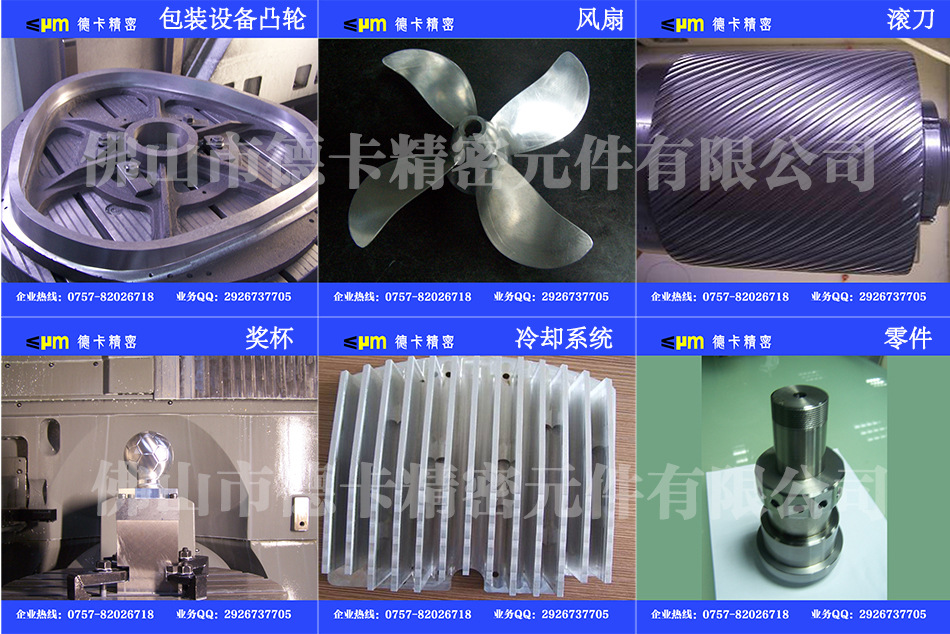

????????Service scope

???????????????????????????????????????????????????????????????????????????????????????????????????????????? Automatic feeding system (including the vibration plate and guide rail) research and development, design and manufacturing; We according to the customer for vibration plate and the workpiece feeding guide the design and manufacturing.

??????????????????:

|

????????????????????????????????????

- ????????????????????????????????????235??????????????????

- ??????????0757-82026718 82026716

- ????QQ??2926737705

- Email:[email protected]

- ????????????deka168

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。