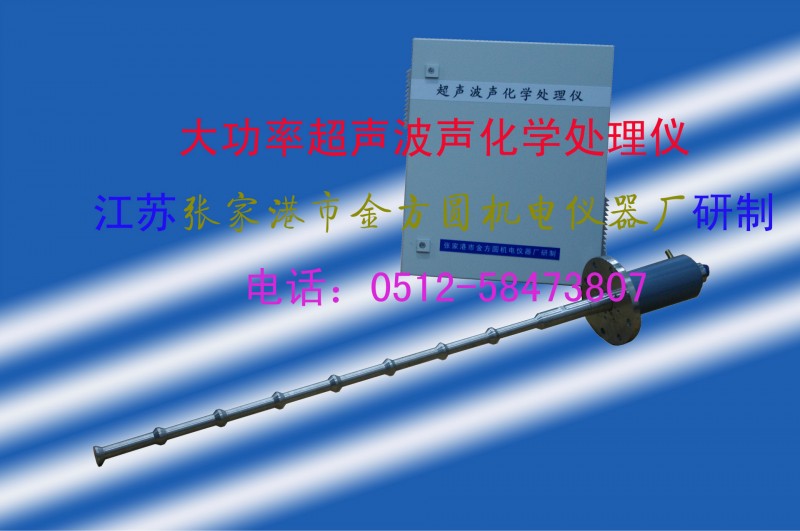

USMY-150N25S Ultrasonic swing procesing machine 一 概述 該機是為聚晶模拋光而專門設計。拋光范圍在0.35MM以上時速度快,可節省多次磨針的時間,從而提高效率。具有加工效率高,質量好和噪音低的優點。能快速地對模具進行整形或拋光,並能快速地使加工麵達到鏡麵。尤其對大規格模具的加工有顯著的作用。 A. An overview 二 技術參數 加工范圍(mm): 0.35-5.00 電源: 220V 50HZ 最大輸出功率(W): 150 換能器: 日式電感式 工作頻率(KHZ): 25 模座轉速(rpm/min):180 模座搖擺(time/min):150 搖擺角度: 不小於12度(可調) B. Technical parameters 三 工作原理及設備構成 本機是利用超音波高速震蕩,通過鋼針及磨料,在被加工麵上產生撞擊,磨削被加工麵,使之達到需要的形狀及尺寸。本設備主要由超音波發生器、換能器、機座三部分組成。 (1)超音波發生器: 超音波發生器被安裝在一個450*210*410*的鐵皮箱子內,為一個超音波電源。線路采用頻率自動跟蹤,對不同的鋼針能自動修正頻率,使之相匹配,從而達到超聲輸出及震蕩效果。 (2)換能器: 換能器為高效磁致伸縮水冷式。具有高效的換能效果,能將超音波轉換成平穩地超聲震蕩,冷卻采用加水循環冷卻,並具有噪音小之特點。 (3)機座:工作臺可旋轉且可前後搖擺機座。工作臺裡麵安裝彈簧一根,可以上下移動,並可任意調整壓力,利用皮帶輪和偏心輪帶動,使前後擺動,擺動幅度約12度,而工作臺被安裝在L型拖板上可以任意地對中心,確保在拋光的過程中,使模具不變形及圓度。後立柱上有一副可以升降移動的拖板,換能器就安裝在這一拖板上。 C.working principle and equipment constitutes 4、安裝及使用: (1) 安裝:把機座放置在平穩的桌麵上,將換能器升降移動調整至合適的位置然後鎖緊,將超音波發生器及砂輪機放置在旁邊,然後用隨機所配的輸出線將超音波發生器與換能器連接起來,而將機座上的電源插頭插入超音波發生器的電源輸出插座上。檢查無誤後,在開關都處於關的狀態下將超音波發生器電源插頭插入帶有牢固接地線的電源插座上。 (2)使用: 根據所需加工模具的大小,選擇合適的變幅桿和鋼針,將鋼針用銀焊條牢固地焊接在變幅桿上。然後在砂輪上磨削出合適的角度,裝在換能器上擰緊。模具放在模座上,調節十字脫板及換能器上下拖板,使鋼針插入模孔內,然後放上磨料,打開超音波電源開關和模座旋轉開關。調節超音波輸出功率旋鈕至適當大小,然後可見磨料在超音波作用下攪動,即模具加工或拋光正在進行中。 D.Installation and Usage (1)Installation. Place the machine base on balanced table, ascend and move the transducer to appropriate position and lock up, set aside the ultrasonic generator and grinding wheel machine, then connect the ultrasonic generator and transducer with output wire assigned by the machine.Insert the power supply plug on machine base into socket of power output on ultrasonic generator.After check-up, insert the power supply pin of ultrasonic generator into power supply socket with stable grounding wire under the condition of close of on-off. (2)Usage. Choose appropriate steel needle based on the size of die processed. Sealed fast steer needle with silver welding rod to breadth changing pole .Then grind into suitable angles on grinding wheel and install and screw down on the transducer. Place the die on model base, adjust the cross board and dragging board of transducer to make the steer needle insert into the model pole, then put on abrasive, open up the switch of ultrasonic power and model base circumrotation. Tune up the knob of export power of ultrasonic wave, the abrasive can be seen to stir under the function of ultrasonic wave. That means die processing or polishing is in operation.

USMY-150N25S超音波搖擺加工專用機

It is specially designed for polycrystalline die polishing. It is quick when the polishing scope is over 0.35MM, saving grinding time to improve efficiency. It has advantages of high processing efficiency, good quality and low noise. It can be able to shape or polish quickly on die, and quickly make the processing side to reach mirror. In particular, it plays a significant role for large-sized mold processing.

Processing range (mm): 0.35-5.00

Power: 220V 50HZ

Maximum output power (W): 150

Transducer: Japanese nickel-chip inductive

Frequency (KHZ): 25

Die-seat speed (rpm / min): 180

Die-seat swing (time / min): 150

Swing angle: not less than 12 degrees (adjustable)

This machine uses ultrasonic high-speed vibration, and via the steel needle and abrasive to strike on the processed surface, grind processed surface to meet the needed shape and size. This equipment consists of ultrasonic generator, transducer and machine base.

(1) ultrasonic generator: ultrasonic generator is installed in a 450mm * 210mm * 410 mm iron box. Line uses automatic frequency tracking, correct automatically frequency of different steel needle to match each other, so as to achieve ultrasound output and shock effect.

(2) transducer: It is pure nickel film of water-cooling type with efficient transducer effect.The ultrasound can be converted into smooth ultrasound shock, using water cycle cooling, and has the characteristic of low noise.

(3) Machine base: Table can be rotated and can swing the machine base forward and backward. With a spring installed inside table, you can move it up and down, and it can adjust the pressure, swing it before and after by eccentric wheel and pulley. The swing margin is about 12 degrees. The platform was installed in the L-plate and can correct center to ensure die non-deformation and roundness in polishing process. The transducer is installed on a pair of board after the column which can be moved up and down.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。