|  |

|  |

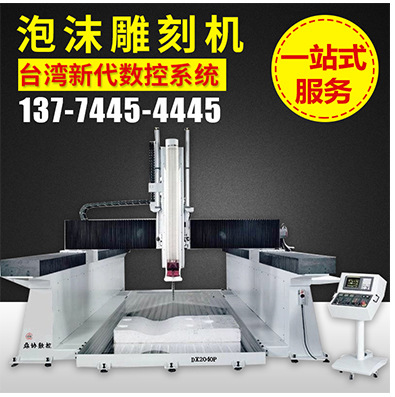

☆特點:

1.經高溫去應力處理的整體鑄造床身,有效保證床體剛性;

2.采用日本NSK軸承和臺灣PMI線性導軌、PMI滾珠絲桿保證加工精度.

3.四個機頭可同時加工,比單機頭提高4倍的效率.

4.臺灣新代控製系統,四軸聯動功能.

5.兼容各類繪圖軟件:Type3, Artcam, Mastercam, UG,文泰等等;

6.控製系統具有路徑模擬、實時加工路徑顯示功能,斷電、斷點繼續功能.

☆應用行業:

歐式羅馬柱、樓梯扶手、筆筒、毛竹工藝品、立體工藝品等各種圓柱式產品的加工。

☆Features:

1. United casting body with stress removal treatment can ensure the solidity.

2. Apply NSK bearings from Japan, PMI linear guiderail and PMI ball screw to ensure higher working accuracy.

3. Four heads work simultaneously to improve productivity.

4. Synetic system with the control of four axes.

5. Compatible with many different software like Type3, Artcam, Mastercam, UG, WenTai, etc.

6.Control system has functions of path simulation and real-time process display, continuous work after power outage or breakpoint.

☆Application fields:

Apply for kinds of cylindrical products and crafts, such as European type column, stair handrail and pen case.

NO. | 性能指標(item) | 型號 | DX1203-C4 |

1 | 工作行程 (travel size) | X軸(X axis) | 300mm |

Y軸(Y axis) | 1200mm | ||

Z軸(Z軸) | 100mm | ||

2 | A軸最大夾持直徑 (Max. diameter for A) | 300mm | |

3 | 結構 (structure) | A結構(A structure) | 高精度分度頭(dividing head with high precision) |

X、Y、Z結構 (X, Y, Z structure) | 臺灣PMI直線導軌,PMI高精度絲桿 (PMI guiderail and ball screw) | ||

4 | 運行模式(working mode) | 伺服電機及驅動(servo motor and driver) | |

5 | 主軸(spindle) | 主軸功率(spindle power) | 4-1.5KW |

主軸轉速(rotary speed) | 0-24000r/min | ||

主軸夾頭(clamper) | ER11 | ||

6 | 工作電壓(working voltage) |

| AC380V/50Hz |

7 | 運行指令(file format) |

| G代碼 |

8 | 刀具直徑(cutting tool) |

| 3.175/4/6mm |

9 | 操作系統(control system) |

| 臺灣新代系統(四軸聯動) |

10 | 外形尺寸(outer size) |

| 2160*1800*2000mm |

11 | 重量(weight) |

| 2400kg |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。