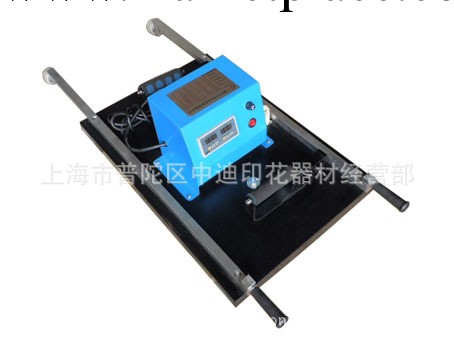

| 類型 | 熱轉印機 | 品牌 | 江川 |

| 型號 | JC-7A | 適用範圍 | 服裝印花,工藝品印花,燙鑽 |

| 產品別名 | 熱轉印機,燙畫機 | 外形尺寸 | 42*42(CM) |

| 重量 | 85 | 主電機功率 | 2.2KW |

技術特點

採用集成電路板,觸摸按鈕,電磁開關技術,通斷計時器,美觀,準確性高;

設備整體結構穩固,不易變形,運行平穩,噪聲小;

全自動控制,壓力平穩均勻,壓力可達8KG/CM2;

工作台可在手動與自動運行之間切換;

採用推拉式工作檯面,操作省力承印速度快;

該機特採用安全保護裝置,防壓傷,非常安全及理性化;

加熱板採用特殊管環繞設計,加熱均勻;

工作檯面特殊處理,可承印昇華、熱轉印、燙金等製品。

JC-7A pneumatic double stations heat transfer machine

operation instruction

Guangzhou Jiangchuan Printing Equipment Co., Ltd.

Add:No.8,Lane1,Puyu Street,Xiushui Village,Renhe Town,Baiyun District,Guangzhou City,China

contents

brief introduction………………………………………………………3

Features………………………………………………………………3

Technical Data…………………………………………………………3

install andoperating instructions…………………………………………3

Breakdown Maintenance andMaintenance…………………………………4

Packing and carrying explanation…………………………………………5

safety Attentions………………………………………………………5

products guarantee……………………………………………………6

products indicator diagram ofspare parts…………………………………7

products Electrical diagrams……………………………………………8

簡介Introduction

本機(JC-7A氣動雙工位燙畫機)可將昇華類,溶劑類油墨的彩色圖案與文字經熱轉印燙在棉,麻,化絨等絨物上,還可進行植毛燙畫和發泡印花工藝等處理,經濟又實用,使用本機前,請認真閱讀本說明後,再進行操作。

The machine (JC-7A Pneumatic Double heat transfer machine) can be sublimation type, solvent type ink color images and text by the heat transfer iron on cotton, linen, velvet, velvet material based on the heat transfer can be flockedand foam printing process such as handling, economy and practical use of this machine, please read this note, then operate

Feature特點

●電子數顯恆溫控制溫度,準確性高(± 2℃);

●(electronic digital thermostat control temperature, high accuracy (± 2℃);

●發熱採用進口鋁合金澆鑄導熱原理,省電,溫度均勻,溫差係數小;

●fever imported aluminum cast heat theory, power, temperature uniformity, temperature coefficient;

●電子時間控制,工序完成訊號指示;

●electronic time control, signal process complete instructions;

●壓力隨意調節。

●pressure adjustable.

Specifications

電壓Voltage(V):220/110

功率Power(KW):2.2 2.5 3.0

溫度範圍Temperature range(℃):0-399

時控範圍When the control range(S):0-999

工作台尺寸Table size(㎝): 40×40 40×60

包裝尺寸Package Size(㎝): 120×85×95 142×85×95

淨重Net weight(㎏):100 120

毛重GW(㎏):30 35

安裝及操作說明:Installation and operating instructions:

1.本機要放置在平穩的地面上,機器四周應有1米以上空間,以方便安裝及維修。The confidential on a stable ground, the machine should be around 1 m or more, to facilitate the installation and maintenance.

2.確定本機安裝位置後,配備單相220V電壓或110V電壓交流電源,電壓波動範圍—10﹪至5﹪在接線前,必須配備220V/110閘刀開關或空氣開關,以便控制機器電源通斷,並必須接可靠地線。Determine the location of the installation, with single-phase 220V or 110V voltage AC power supply voltage, the voltage fluctuation range -10% to 5% in the terminal before, must be equipped with 220V/110 knife switch or air switch to control the machine power off, and reliable ground must be connected.

3.安裝完畢後,再認真檢查一次,以免接誤。After installation, and then carefully checked to prevent access errors.

4.連接所配壓縮機氣接頭,打開氣壓,將壓力表調製(4pB-6pB)使發熱板升起;Connection with joint air compressor, open the pressure, the pressure gauge modulation (4pB-6pB) board rise to fever;

5.插上電源,打開電源總開關,電源指示燈隨即著亮;操作過程中由於發熱板溫度較高請嚴禁觸摸,以免燙傷;Plug in the power, turn on power switch, power indicator light then the light; operation at high temperature because of fever, please non-touch panel, so as not to burn;

6.將恆溫器調較至所需溫度(通常為120℃-200℃);The thermostat adjusted to the desired temperature (usually 120℃-200℃);

7.將定時器調較至所需時間(通常為10至30秒左右);Adjust the timer to time (usually 10 to 30 seconds);

8.將衣物平放在下燙板上,再疊上燙畫紙(注意:燙畫紙的正反面,所燙圖案四邊必須小於工作台外圍尺寸0.5厘米以上)推動工作檯面到燙壓位置即可;Will be the next hot clothing and flat panel, and then stacked on the transfer paper (Note: heat transfer paper is negative, the hot table pattern edges must be less than 0.5 cm above the external dimensions) to promote the work surface to a hot pressure location can be;

9.當指示燙印的定時時間到時,發熱板自動升起,將另一工作台推到位,發熱板自動下壓。The timing when the instruction time to time stamping, hot plate automatically rises, pushing the other table in place, heating plate under the pressure automatically.

10.經常保持工作台表面清潔,每月應對各軸承及導柱等經常傳動部件進行注油潤滑。為使燙印效果更好,溫度均勻,不要放在大風吹到處,並保持平衡。Keep the table surface is clean, a monthly column should guide the bearings and transmission parts such as grease lubricated regularly. In order to better stamping, temperature uniformity, do not put the wind blows everywhere, and balance.

11.如果是冷撕的燙畫紙,請用黑板擦將燙畫紙均衡擦一遍,等5-20秒,才將燙畫紙撕掉;如果是熱撕的燙畫紙,燙印完畢請馬上將燙畫紙撕去。

成功的燙印需要有正確的時間,溫度及壓力的配合,衣物的厚度和材料及燙畫紙的種類都影響到燙印的效果。

(注意:各種燙畫紙都需試燙小樣認可後,方可批量生產。)

If it is cool, peel the transfer paper, please use the eraser to wipe the balance transfer paper, such as 5-20 seconds before the transfer paper torn; If it is hot tear of the transfer paper, hot stamping is completed, please immediately transfer paper torn off.

Successful stamping requires the right time, the temperature and pressure with, clothing and materials and the thickness of the type of transfer paper are affected stamping effect.

(Note: all kinds of transfer paper are subject to approval sample test hot, before mass production.)

故障維修及維護Fault repair and maintenance

1.壓力:如壓力不夠均勻,可調較發熱板中心的四條絲桿,向下是增加壓力,向上是減少壓力,壓力最大可調至8PB。

1. Pressure: If pressure is not enough even, adjustable center of plate heat four screw down to increase pressure to reduce the upward pressure, the greatest pressure adjustable to 8PB.

2.時間:當燙印時間到達而發熱板未升起,則須檢查電磁閥觸點是否燒壞或時間表是否燒壞。

2. Time: When the transfer time to reach the hot plate does not rise, shall check whether the contact valve is burned burned or timetable.

3.溫度:當所調溫度到達時,溫控器液晶會顯示已到所需溫度,如不升溫,則檢查1接觸器是否壞了;2溫度表是否失靈;3發熱管是否燒壞;4高溫線是否脫落。

3. Temperature: When the temperature reaches transfer, the temperature control liquid crystal displays has been to the desired temperature, such as not warming up, check1contactor is bad;2thermometer is malfunctioning;3heat pipe is burned;4high-temperature line is off.

4.發熱板不下壓:1檢查工作台是否到位;2氣壓是否在4pB以上;3感應開關是否與磁鐵感應;4時間表是否計時,會計時,則說明感應開關,沒問題則檢查觸點電磁閥;5電磁閥是否有電,有電而不動作,則是電磁閥壞。

4. Heating plate no less than pressure:1Check if table in place;2pressure over whether 4pB;3whether the magnet sensing switch sensing;4schedule is time, accounting, then shows sensor switch, no problem, check the contact solenoid valve;5solenoid valve if there is power, and electricity without action is a bad solenoid valve.

註:過濾器壓力應調到(4pB-6pB)如發熱板未升起,請栓查氣壓線路,電磁閥是否暢通,過濾器是否打開,過濾器建議每1000L壓縮空氣中加入1-12滴SNS-01(ISOVG32)油霧器專用油(透平1號油);每隔一定時間請檢查導柱及軸承的潤滑黃油是否變干,如變干則需添加適量3#通用鋰基脂即可。

Note: The filter pressure should be transferred to (4pB-6pB), such as heating panels are not raised, please search bolt pressure line, the electromagnetic valve is smooth, the filter is open, compressed air filters recommended that each 1000L adding 1-12 drops of SNS -01 (ISOVG32) Lubricator special oil (turbine oil No. 1); intervals check the lubrication of guide columns and the bearing grease is dry, add the appropriate amount, such as dry Zexu 3 # Lithium Grease can

包裝及搬運說明

用木箱包裝時:外包裝採用全封圍板木箱包裝,用可承重100公斤以上叉車搬動;不用木箱包裝時,可兩到三人兩手抓緊機器前後手把位置平穩抬動機器,輕輕放下即可。

Packaging and handling instructions

With the wooden box packaging: packing a fully sealed wooden packing panels, with the forklift can carry the load of 100 kg or more; not packed in wooden cases, they can lose two or three hands before and after the hand position of the smooth machinery lifting machinery, you can gently put down.

安全注意事項Packaging and handling instructions

整機必須放置於水平地面,進行操作前必須有合適牢靠的保護地線,機器操作過程中禁止觸摸該機發熱板發熱處,機器如出現故障以及需咨詢事宜,請與當地代理商或廠家聯繫。

With the wooden box packaging: packing a fully sealed wooden packing panels, with the forklift can carry the load of 100 kg or more; not packed in wooden cases, they can lose two or three hands before and after the hand position of the smooth machinery lifting machinery, you can gently put down.

Safety Precautions

Machine must be placed on level ground, the former must have the right to operate the protection of solid ground, touch the machine during the operation of aircraft against heat plate heat Department, machinery such as failure and the need consultation, please contact local dealer or manufacturer .

印花設備及熱轉印設備保修單

Printing equipment and heat transfer equipment warranty

產品型號Model::出廠編號serial number::

保修條例Warranty

1.在保修期內憑此單和送貨單(或收款收據)修理;

1.Harbor has enabled one in the warranty period and delivery note (or receiving a receipt) repair;

2.保修期限:從出售起電器配件保修一年。Warranty period: from the sale of electrical accessories from year warranty.

3.保修注意事項Warranty Notes:

◆凡未經拆動,確屬產品製造不良的故障或損壞,均由我廠負責修理或更換損壞的零配件;對使用不當等人為製造的故障或損壞,不屬保修範圍;

◆whatever is not dismantled, are indeed poor manufacturing fault or damage by the factory for repair or replacement of defective parts; on the use of man-made improper failure or damage, not a warranty;

◆燈管,保險絲,彈簧,硅膠,海棉,高溫布,皮帶等非電器配件不在保修範圍;

◆lamps, fuses, springs, rubber, sponge, high temperature fabrics, belts and other non-electrical accessories not covered under warranty;

◆用戶與我廠聯繫解決質量問題時,請寫明機器型號,出廠編號,故障現

user contact with our factory to solve quality problems, please specify the machine model, serial number, fault phenomenon.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。