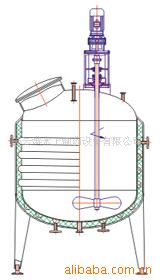

配料罐:本配料罐又名攪拌罐、配料桶,有節能、耐蝕、生產能力

強、清洗方便,結構簡單等特點,主要用於奶品和食糖、飲料及其他元素和各種物料在配合後進行攪拌均勻作用。是製造乳品、飲料、製藥廠傢不可缺少的設備。

結構:本設備分罐體、罐蓋、攪拌槳、進料口、出料閥均有由進

口不銹鋼耐酸銅1cr18Ni9Ti製成,按GB741-80技術條件進行,罐體內外拋光,罐內有攪拌槳,工作時起攪拌作用;上蓋有溫度計,顯示罐內溫度;頂部有擺線針輸行星減速器,帶動攪拌槳;並可裝拆與清洗,並是一扇可開式罐蓋供清洗用,另加兩個進料口,可與管道連接,便於連接進各種配料,下麵帶有出料口,並裝上旋塞閥大等攪拌均勻後、旋轉旋塞閥手柄90°即可放料,放料完畢關閉,達到攪拌均勻目的。

This equipment uses for mixing and storing liquid materials on traditional medicine, food and chemical industry. It can absorb the steam or cooling water into the sandwich sleeve so as to let the materials be at the best temperature. The mixer is imported from Germany. It can exempt the material sediment. The driving part adopts the mechanical seal to ensure no pollut-ion. It's an initial selectable equipment for thick or thin prescription of inje-ction agent and large transfusion medicine liquid, with advantages of high efficiency and convenient operation. The tanker inside equ ips with automatic rotary spray head to ensure thorough cleaning. It adopts SUS304 or 316L stainless steel and carries out the mirror face polish treatment in accordance with GMP standard.

技術參數Technology Parameter:

規格(L)

| 參考尺寸(mm)

| ||||||

D

| D1

| H1

| H2

| H3

| δ

| DN

| |

100

| 400

| 600

| 400

| 1050

| 250

| 3

| 32

|

150

| 400

| 600

| 400

| 1450

| 250

| 3

| 32

|

200

| 500

| 700

| 400

| 1450

| 250

| 3

| 32

|

300

| 600

| 800

| 400

| 1450

| 250

| 3

| 32

|

500

| 800

| 1000

| 500

| 1350

| 330

| 4

| 40

|

600

| 800

| 1000

| 00

| 1550

| 330

| 4

| 40

|

1000

| 1000

| 1200

| 700

| 1750

| 330

| 5

| 40

|

1200

| 1000

| 1200

| 700

| 1950

| 330

| 5

| 40

|

1500

| 1100

| 1300

| 700

| 1950

| 330

| 5

| 40

|

2000

| 1400

| 1600

| 700

| 1650

| 330

| 5

| 40

|

2500

| 1400

| 1600

| 800

| 2000

| 330

| 5

| 40

|

3000

| 1500

| 1700

| 800

| 1900

| 330

| 6

| 40

|

4000

| 1700

| 1900

| 900

| 2100

| 330

| 6

| 40

|

5000

| 1700

| 1900

| 900

| 2850

| 400

| 6

| 50

|

6000

| 1800

| 2000

| 1000

| 2850

| 400

| 6

| 50

|

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。