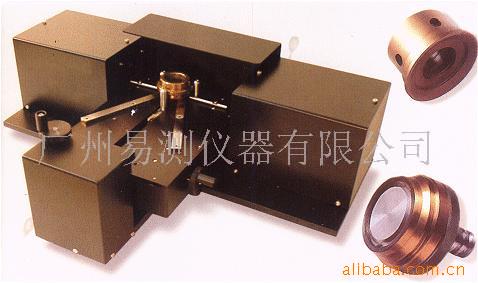

滾輪壓頭外形機,製罐行業專用

| Distance from roll bottom to groove 5Omm (custom distances upon request) | 5mm calibration resolution |

| Roll/Chuck diameter 45-175mm (custom diameters upon request) | Calibration gauge (NAMAS optional) |

| 8.5mm resolution scan | Interfaces with AutoCAD? |

| High angle measurements (89 degrees) | Prints profiles at 50:1 scale (variable) |

| Auto radius/angle measurements | Compare profiles with bitmap files |

| Windows 9X/NT application | Profile and report database |

| Multilingual | Automatic angle/radius measure |

| Manual distance/angle/radius measurement |

| Acceptance testing When receiving rolls or chucks from an existing, or new supplier - it is recommended to verify that the rolls are precisely the same as known good rolls. Any new parts going into the seamer (particularly those as important as rolls or chucks) should be inspected before they are installed! As the image shows, there are often major differences between rolls produced by two different manufacturers, using the same original diagram as a specification! The red arrows were added to show the areas with the most differences between the rolls. |  |

| Quality Control It is often important to know how corrosion and high usage effect the profile. In some instances a small change in roll design may improve durability. The effect of wear and tear can be shown in this image, wher the green profile is brand new and the blue profile shows the same roll after producing approximately 40 million cans. The red arrows were added to show areas wher corrosion has effected the roll profile the most. |  |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。