| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

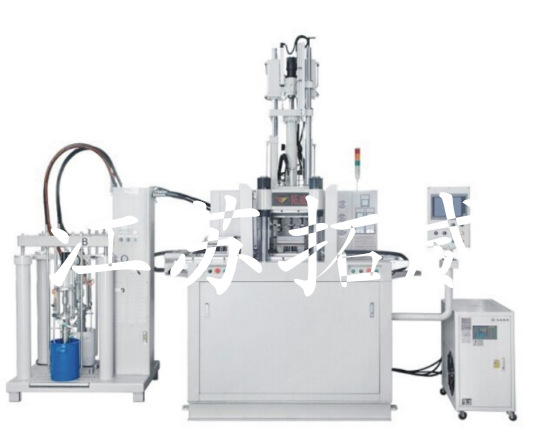

| 機臺特點 固定式四缸平衡立式註射結構,超穩定的註射受力 。 優化的射料桿大大減少瞭漏膠量,維修、換膠方便快捷 。 "創新射料管恒溫系統加超短的射嘴,使餘料極少和最小的壓力損。 500T以下規格采用國際流行的FIFO先進先出註射方式 。 全封閉安全擋板與光柵,更高的設備操作安全等級 。 熱板加熱分區控製,溫度更均勻 。 更大的臺麵設計。 更多的自動化功能可供選配。 Machine characteristics Stationary four cylinders balancing vertical injection structure, hyperstatic injection force. Optimized shot feeding rod greatly reduces the rubber leakage and is convenient and fast for maintenance and rubberreplacement. “Innovative shot feeding tube constant temperature system plus ultrashort nozzle make very few remaining materials and minimum pressure loss ”. Specification under 500T adopts the international popular and advanced FIFO first-in first-out injection way . Totally-enclosed safety shield and grating, higher equipment operation safety grade. Hot plate heating zone control makes temperature more even. Bigger table board design. More automatic functions may be selected. |

| 適用產品:各種橡膠產品。 | ||||

| Applicable products:Various rubber products | ||||

| 標配裝置 | Standard unit | |||

| 高效率比壓比流液壓系統 | Efficient specific pressure and flow hydraulic system | |||

| 上機械吊模 | Upper machinery lifting mold | |||

| 下出入模裝置 | Lower in and out mold unit | |||

| 二層脫模裝置 | Two-level demoulding device | |||

| 全封閉安全擋板與光柵 | Totally-enclosed safety shield and grating | |||

| 塑化、註射獨立溫控系統 | Plasticizing and injection independent temperature control system | |||

| 熱板加熱分區控製 | Hot plate heating zone control | |||

| 西門子控製器 | Siemens controller | |||

| 選配裝置 | Optional device | |||

| 變量泵系統 | Variable pump system | |||

| 冷流道裝置 | Cold runner device | |||

| 3RT/4RT多層脫模裝置 | 3RT/4RT multilayer demoulding device | |||

| 中模出入裝置 | Middle mold in-and-out device | |||

| 拉爪裝置 | Claw device | |||

| 模具抽真空系統 | Mold vacuum system | |||

| 快速換模裝置 | Quick mold change device | |||

| 遠程控製 | Remote control | |||

| 打印功能 | Print function | |||

| 可預製模具加熱功能 | May preset mold heating function | |||

| 可增加註射量 | May increase injection volume | |||

| 技術參數Specificaton | ||||

| 鎖合模單元/機型Type | TWL-200T | TWL-300T | TWL-400T | TWL-500T |

| 出力Clapping force(TON) | 200 | 300 | 400 | 500 |

| 行程Stroke(MM) | 500 | 500 | 600 | 600 |

| 工作臺麵Working Plate Size(MM) | 600×600 | 700×700 | 700×800 | 800×850 |

| 主油缸直徑Dimeter of cyhnder(MM) | 355 | 450 | 500 | 560 |

| 最大熱板間距Max plate spacie(MM) | 550 | 550 | 700 | 700 |

| 最小模厚Min Mould Height(MM) | 60 | 60 | 100 | 100 |

| 吊模行程Crane travel(MM) | 200 | 200 | 250 | 250 |

| 托模行程Joe trabel(MM) | 200 | 200 | 250 | 250 |

| 射出單元injection unit | ||||

| 註射容積Volume injection(CC) | 2000 | 3000 | 4000 | 5000 |

| 註射壓力Injection pressure(Mpa) | 220 | 220 | 205 | 205 |

| 螺桿直徑Screw diametre(MM) | 45 | 45 | 55 | 55 |

| 射嘴孔徑Nozzle aperture(MM) | 6 | 6 | 7 | 8 |

| 其它OTHERS | ||||

| 系統壓力System pressure(Mpa) | 21 | 21 | 21 | 21 |

| 馬力Horse powet(HP) | 15 | 20 | 25 | 30 |

| 電熱功率Heater power(KW) | 19 | 22 | 27 | 31 |

| 總功率Total power(KW) | 36 | 40 | 52 | 58 |

| 重量Gross weight(KG) | 7200 | 9300 | 11700 | 14700 |

| 機臺尺寸Machine size(MM) | 2700×1200×3600 | 3100×1300×4000 | 3300×1400×4500 | 4000×1600×4500 |

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。