| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

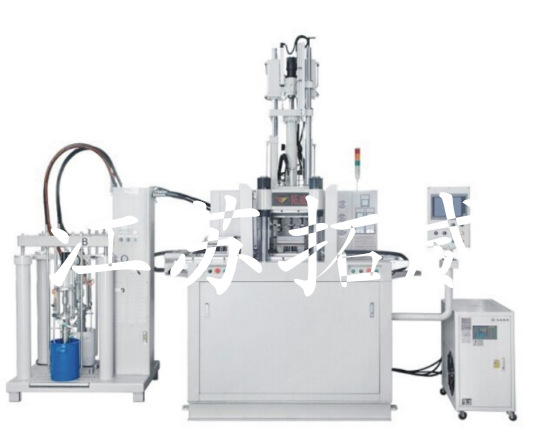

| 臥式矽橡膠註射成型機系列(先進先出) | ||||

| Horizontal silicon rubber injection molding machine series (first-in, first-out) | ||||

| 機臺特點 采用歐美先進設計理念的先進先出註射結構,註射力穩定,可靠。 優化的射料桿大大減少瞭漏膠量,維修、換膠方便快捷。 超大容量送料結構,發明專利自動可旋轉式送料筒,省時省料,適合不同顏色及不同性能的膠料快速更換生產。 500T以下規格采用國際流行的FIFO先進先出註射方式。 全封閉安全擋板與光柵,更高的設備操作安全等級。 熱板加熱分區控製,溫度更均勻。 更大的臺麵設計。 更多的自動化功能可供選配。 Machine characteristics Adopt first-in-first out injection structure of European and American advanced design concept, and the injection force is stable and reliable. Optimized shot feeding rod greatly reduces the rubber leakage and is convenient and fast for maintenance and rubber replacement. Large capacity of feeding structure and the automatic rotary feeding tube with a patent for an invention . saves time and materials and is suitable for fast replacement and production of different color and property of rubber materials. Totally-enclosed safety shield and grating, higher equipment operation safety grade . Hot plate heating zone control makes temperature more even. Bigger table board design. More automatic functions may be selected. 適用產品 電力絕緣產品、醫療用品、廚房用品等 Applicable products Electric insulation product, medical products and kitchen wares, etc. | ||||

| 標配裝置 | Standard unit | |||

| 高效率比壓比流液壓系統 | Efficient specific pressure and flow hydraulic system | |||

| 上機械吊模 | Upper machinery lifting mold | |||

| 下出入模裝置 | Lower in and out mold unit | |||

| 二層脫模裝置 | Two-level demoulding device | |||

| 全封閉安全擋板與光柵 | Totally-enclosed safety shield and grating | |||

| 塑化、註射獨立溫控系統 | Plasticizing and injection independent temperature control system | |||

| 熱板加熱分區控製 | Hot plate heating zone control | |||

| 西門子控製器 | Siemens controller | |||

| 選配裝置 | ptional device | |||

| 變量泵系統 | Variable pump system | |||

| 冷流道裝置 | Cold runner device | |||

| 3RT/4RT多層脫模裝置 | 3RT/4RT multilayer demoulding device | |||

| 中模出入裝置 | Middle mold in-and-out device | |||

| 拉爪裝置 | Claw device | |||

| 模具抽真空系統 | Mold vacuum system | |||

| 快速換模裝置 | Quick mold change device | |||

| 遠程控製 | Remote control | |||

| 打印功能 | Print function | |||

| 可預製模具加熱功能 | May preset mold heating function | |||

| 可增加註射量 | May increase injection volume | |||

| 技術參數Specificaton | ||||

| 鎖合模單元/機型Type | TWW-200T | TWW-300T | TWW-400T | TWW-500T |

| 出力Clapping force(TON) | 200 | 300 | 400 | 500 |

| 行程Stroke(MM) | 500 | 500 | 600 | 600 |

| 工作臺麵Working Plate Size(MM) | 600×600 | 700×700 | 700×800 | 800×850 |

| 主油缸直徑Dimeter of cyhnder(MM) | 355 | 450 | 500 | 560 |

| 最大熱板間距Max plate spacie(MM) | 550 | 550 | 700 | 700 |

| 最小模厚Min Mould Height(MM) | 60 | 60 | 100 | 100 |

| 吊模行程Crane travel(MM) | 200 | 200 | 250 | 250 |

| 托模行程Joe trabel(MM) | 200 | 200 | 250 | 250 |

| 射出單元injection unit | ||||

| 註射容積Volume injection(CC) | 2000 | 3000 | 4000 | 5000 |

| 註射壓力Injection pressure(Mpa) | 188 | 182 | 178 | 178 |

| 螺桿直徑Screw diametre(MM) | 45 | 45 | 55 | 55 |

| 射嘴孔徑Nozzle aperture(MM) | 6 | 6 | 7 | 8 |

| 其它OTHERS | ||||

| 系統壓力System pressure(Mpa) | 21 | 21 | 21 | 21 |

| 馬力Horse powet(HP) | 15 | 20 | 25 | 30 |

| 電熱功率Heater power(KW) | 19 | 22 | 27 | 31 |

| 總功率Total power(KW) | 36 | 40 | 52 | 58 |

| 重量Gross weight(KG) | 7500 | 9600 | 12000 | 15000 |

| 機臺尺寸Machine size(MM) | 3400*1600*3000 | 3900*1800*3400 | 4300*2100*3900 | 4600*2300*4200 |

江蘇拓威機械有限公司(原金壇市建陽機械有限公司)是一傢生產橡膠成型機專業製造商。擁有一支經驗豐富技術團隊,不斷研發、製造、銷售並提供一服務。為全球打造高品質橡膠設備。是橡膠加工廠商首選品牌。

公司成立於1996年,位於老牌重工業城市常州金壇,占地麵積30000平方米,公司主要生產:矽橡膠註射機、液態矽膠註射機、液體矽膠泵料機、真空平板硫化機、大型柱式、框式平板硫化機等各種非標設備。

我們以誠信為本﹑質優價廉取勝,時刻傾聽每位客戶的意見,從而提高產品的質量與信譽,在平等互利的基礎上共同發展,共創佳績。拓威機械將繼續致力於質量第一,客戶至上的企業宗旨,以更優﹑更新的產品及優質的服務,不斷提高。

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。