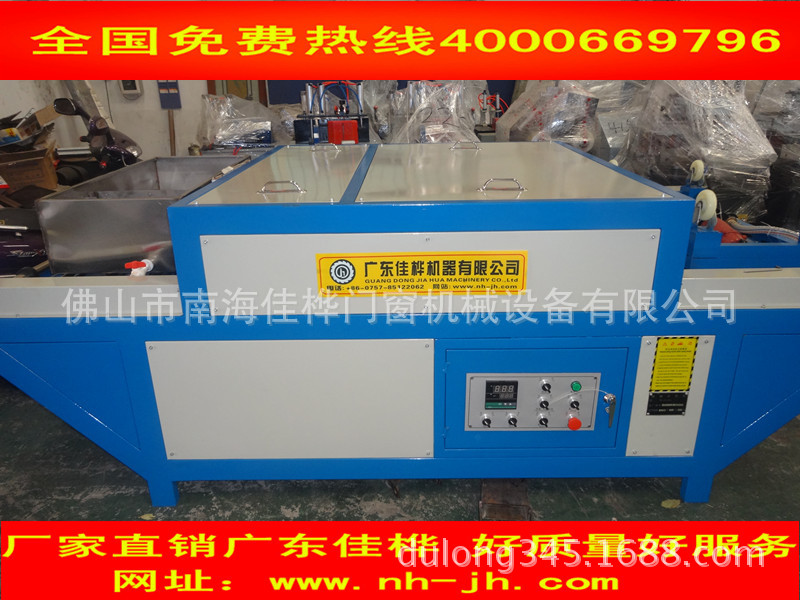

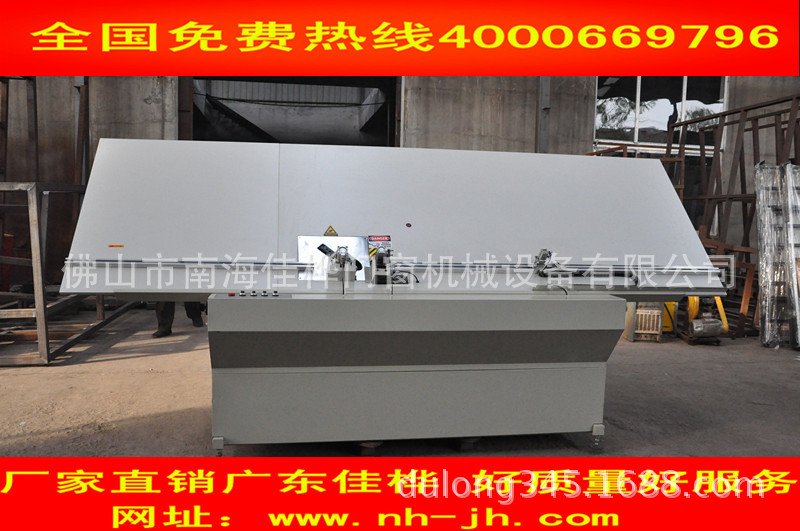

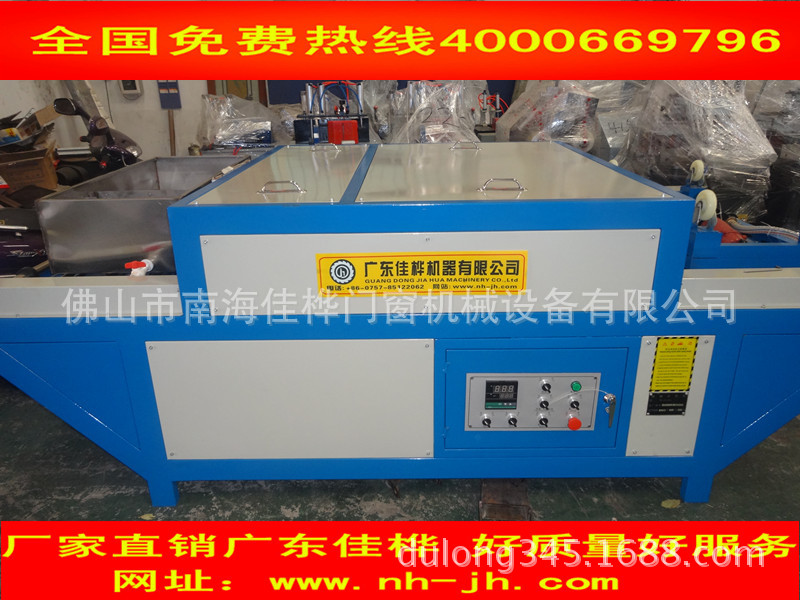

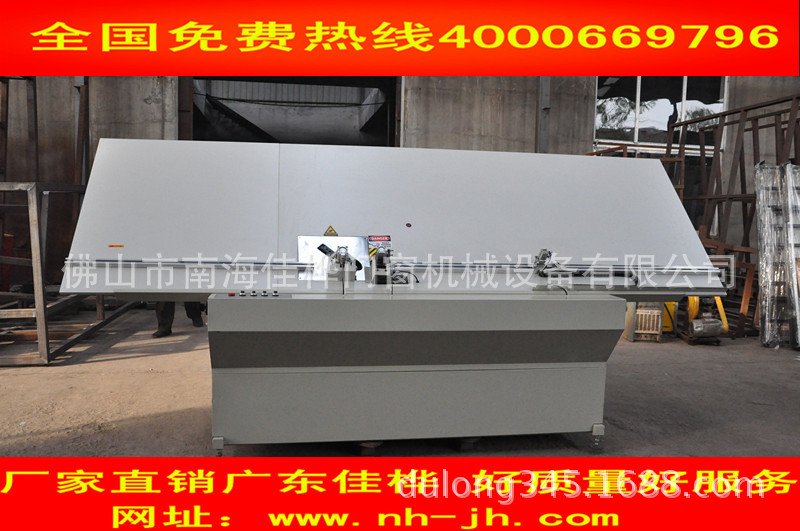

1 全自動數控中空玻璃生產線(可生產LOW-E中空玻璃)。

2 整機采用PLC控製設備運轉觸摸屏人機界麵,板壓段具有電路、氣路自動診斷功能。

3 采用進口真空發生器和吸盤,玻璃吸合效果更佳。

4 可生產二層、三層、大小片等異型中空玻璃。

5 全距離自動變頻調速,節省勞動等待時間,提高生產效率。

6 玻璃合片時平壓機前後箱機械手杠桿式托料,(機械式硬限位+活動板吸盤吸附)

確保自動合片時玻璃永不錯位。

Brief Introduction

- It is a completely automatic insulating glass production line (can produce LOW-E Insulating glass).

- Then entire machine adopts the PLC controls the working condition.

- Adopts the imported vacuum generator and sucker, the suction effect to the glass could be much better.

- bases the customers¡ˉ different request, the entire machine can be improved and produce the Step IG Unit and three Piece IG production.

- Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

- When glass is pressed, the front and back part of flat pressing machine willup the glass with lever- type arm and hand system,( mechanical position + mobile sucking system) all this will ensure no malposition.

技術參數Technical Parameter

輸入電源 Input voltage 380V 50Hz

輸入功率 Input power 19.5Kw

最大加工尺寸 Minimum processing size 1800×2500mm

最小加工尺寸Minimum processing size 280×400mm

原片玻璃厚度 Glass thickness 3~18mm

傳送速度 Travel speed 8~45m/min

外形尺寸Overall dimensions 16000×2350×2680mm

總重量 The total weight 5500kg