- 適用年齡:-

- 功能:其它

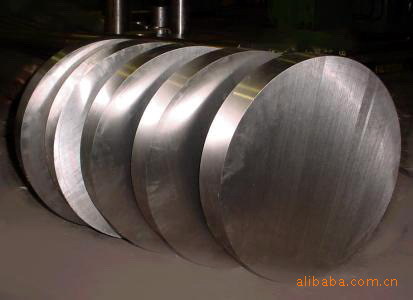

| 品名:塑料模具鋼 | 規格:齊全 |

| 材質:1.2085(X33CrS16) | 產地/廠家:德國 |

Properties

Alloyed stainless martensitic chromium steel with high corrosion resistance, with very good machinability, uniform strength within the whole cross-section at all dimensions and good mechanical damage resistance.

It is a modification of steel 1.2316 with sulfur addition, due to which steel 1.2085 features higher machinability.

The steel is supplied in treated condition and there is no need for subsequent heat treatment (the delivered condition is exploited). Subsequent heat treatment is recommended only in exceptional events when higher hardness is required.

Strength in the delivered condition 930 - 1080 MPa (33 HRC).

Hardness in the delivered condition max. 290 - 320 HB.

Hardness in the soft annealed condition max. 230 HB.

Obtainable hardness after quenching 48 HRC.

The steel is suitable for moulds frameworks of all dimensions, above all for chemically aggressive plastic materials processing and for moulds working in humid climatic conditions.

The steel is not suitable for shaped parts forming a part’s outline.

| Soft annealing | 850 - 880°C |

| Stress relief annealing | 600 °C |

| Quenching temperature | 1000 - 1050 °C |

| Quenching medium | olej, vakuum |

| Drawing temperature | 150 - 550 °C |

| Hardness after quenching | 48 HRC |

| C | Si | Mn | P max | S max | Cr | Ni |

| 0,28-0,38 | ≤ 1 | ≤ 1 | 0,030 | 0,05-0,1 | 15,0-17,0 | ≤ 1 |

1.2085(X33CrS16)

屬性

不銹鋼合金具有高耐腐蝕性馬氏體鉻鋼,具有非常良好的加工性能,在整個橫截面等強度在各方面的阻力和良好的機械損傷。

這是一個與硫鋼1.2316修改此外,由于該鋼具有更高的切削性能1.2085。

的鋼鐵供應治療條件,也沒有必要為以后的熱處理(交付條件是剝削)。隨后的熱處理建議,只有在特殊事件時,需要較高的硬度。

在交付條件強度930 - 1080兆帕斯卡(33 HRC)的。

硬度最大的交付條件。 290 - 320乙型肝炎。

硬度最大的軟退火條件。 230高亮度。

淬火后硬度索取48人權委員會。

應用

該鋼是為所有尺寸,化學腐蝕性的塑膠材料加工和模具在潮濕氣候條件下工作最重要的是合適的模具框架。

鋼材是不是形成一個零件的輪廓形狀合適的零件。

熱處理

軟退火850 - 880 ° C間

應力消除退火600℃

淬火溫度一零零零年至1050年° C間

淬火介質olej,vakuum

拉伸溫度150 - 550℃

淬火后硬度48人權委員會

Chemická analyza

?姒嘸嗯P最大s最大鎳鉻

0,28-0,38≤1≤1≤1 0,030 0,05-0,1 15,0-17,0

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。