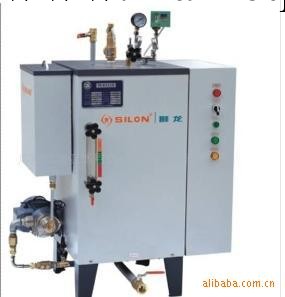

我公司生產的快速反應紗線真空給濕蒸紗機,能提供一個極具成本效益的方法來提高紗線質量品質。該機可對紗線進行熱定型.給濕處理,均勻滲透,有快速反應蒸紗增加棉紗重量的功能,增重達1.7%-…3%,增加毛紗重量多達2.4%--4%。

蒸紗前 Before the yarn steaming, | 蒸紗後After the yarn steaming, | ||

Root /10m(2mm) | Root /10m(3mm) | Root /10m(2mm) | Root /10m(3mm) |

158.5 | 39 | 134.8 | 31.5 |

回潮率 Regain:7.22% | 回潮率 Regain:11.02% | ||

Our company produces the rapid reaction yarn vacuum for the wet yarn steaming machine, can provide to have the cost benefit the method to improve the yarn quality quality extremely. This machine may carry on the heat setting to the yarn. For the wet treatment, the even seepage, has the rapid reaction yarn steaming to increase the cotton yarn weight the function, increases is 1.7%-…3%, increases the wool yarn weight to reach 2.4%--4%.

蒸紗前 | 蒸紗後 | ||

根/10m(2mm) | 根/10m(3mm) | 根/10m(2mm) | 根/10m(3mm) |

158.5 | 39 | 134.8 | 31.5 |

回潮率:7.22% | 回潮率:11.02% | ||

Second, the rapid reaction steams the box “steams the box” the superiority:<dnt> the </dnt>1. craft time is short, saves the energy, compares with the traditional yarn steaming machine, the energy conservation reaches 76%

. the quality to be stable, the temperature, the humidity accuracy control enables each production lot to obtain same level processing.<dnt> the </dnt>3. investment recoupment period is short, is lower than the import equipment investment cost, is more obvious than the home equipment energy conservation.

. non-impact processing, non-condensation spot.

. both can the attemperation, and can adjust the humidity.

. suits processes the car, to transport the yarn which the gauze box loads.

. may process each kind natural and the synthesis staple fiber yarn, mixes reels thread

. Third, yarn heat setting

. model yarn steaming craft step <dnt> the </dnt> vacuum - - preheating - - adds the wet - - heat preservation. The constant temperature - - vacuum temperature decrease - - finished

. unique preheating system

in the yarn steaming process, on the yarn water dro spot will be the common problem, the water dro spot will cause dyeing as well as latter working procedure other questions, therefore, the yarn steaming preheating craft was the absolutely necessary, particularly wool yarn.

.Yarn thermal fixation <dnt> the </dnt> each production working procedure (reels thread, twisting, weaving ......) to be able to cause the gauze and the textile fiber tensity effect, the tensity function can cause the gauze tangle. After the tensity and the tangle can give, a working procedure brings the question, but the artificial fiber mol structure s stress relaxation is had the textile fiber the contraction, therefore, the astute machinery produces the yarn steaming machine has brought the best choice for the yarn production.<dnt> the </dnt> research indicated that the following type s yarn must use the yarn steaming to carry on the relaxation and the setting: The cotton yarn, the wool yarn, the polyester-cotton blend reel thread, the polyester fiber gauze, Bao Xinsha (ammonia black silk ribbon), the tailoring line, the man-made staple fiber yarn, the acrylic fiber silk to tie, the mesh knitted fabric (crimped fibre).

each raw material needs the specific processing craft to achieve the ideal effect,

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。