| 功能 | 充填、灌裝、封口、計量、條碼識別、打印、貼標籤、打碼、噴碼、其他 | 品牌 | 中包 |

| 型號 | DXD-F80C | 電壓 | 220(V) |

| 功率 | 260(Kw) | 包裝膜寬 | 160(mm) |

| 製成袋尺寸 | 50-120/40-80(mm) | 包裝速度 | 30-60(袋/分鐘) |

| 重量 | 260(kg) | 外形尺寸 | 1100*800*1600(mm) |

| 包裝材料 | 薄膜 | 包裝類型 | 袋 |

| 自動化程度 | 全自動 | 適用對像 | 鮮奶、穀物、其他 |

| 適用行業 | 餐飲、食品、化工、日化、其他 | 物料類型 | 粉劑 |

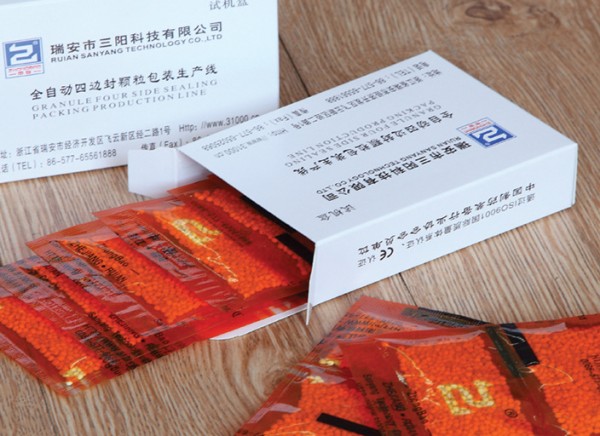

DXD-F80C三邊封粉末包裝機

特點:

1、本設備採用進口PLC可編程控制器,並配置顯示屏操作,從而使設備操作簡單,設定方便,自動化程度高。

2、採用先進的光電控制系統,袋子長度可在顯示屏直接設定,且拉袋平穩,對版準確。

3、採用全不銹鋼外罩,耐腐蝕性高,清理衛生方便,符合GMP要求。

4、採用螺桿計量的粉末加料裝置,且調節方便、計量準確。

5、自動完成制袋、計量、充填、封合、切斷、計數、打印批號等功能。切斷方式可選用平切、連袋點切或鋸齒形,並可選配色帶打印機。

用途:

該機適用於包裝具有一定流動性、較鬆散狀、不同的各種粉末物品,如麵粉、咖喱粉、藕粉、豆奶粉、奶粉、壯骨粉、各種沖劑、營養食品等物料的連續自動包裝。

| 技術參數 Main technological parameter: | ||||

| Bag length | 袋長範圍: | 50-250mm | ||

| Bag width | 袋寬範圍 | 50-140mm | ||

| Applicable film | 包裝速度 | 15-50次/分(按袋子規格與物料而定 depend by pouch size & material) | ||

| Packing dosage | 填充容量 | 1-150ML | ||

| Max film width | 包材寬度 | 350mm | ||

| Mac film diameter | 包材外徑 | 300mm | ||

| Film core diameter | 包材芯徑 | Φ75mm | ||

| Electric source | 接入電源 | 220v 50HZ(可按客戶要求) do as customer's request | ||

| Total power | 總功率 | 6KW | ||

| G.W. | 毛重 | 650Kg | ||

| Package size | 包裝箱尺寸 | 1400*1000*2000MM(L*W*H) | ||

| Applicable film | 適應包材 | PET/AL/PE, PET/PE, NY/PE, NY/AL/PE | ||

Feature:

1.Two-step roller four-side sealing, continuous running not only fast in speed, stable in running, low in noise, but also firm in sealing, reliable in airtight, with bags coming smoothly and fine, high in packing efficiency.

2.An imported frequency changer is adopted for step-less speed adjusting, intelligent temperature control regulates the temperature at the sealing. It has reliable performance, convenient operation.

3.Photoelectric tracking system is adopted to ensure the automatic correcting of the double face printing design on the packing bags, precise in counting.

4.An imported transducer is adopted to make adjusting easy. Intelligent temperature controller regulates sealing making it even more convenient.

5.step motor/servo motor driver is adopted, pouch length can be setup directly at the touching screen, at the same time longitudinal sealing and transverse sealing be able to auto in-phase tracking, it saves more time and material compare to mechanical driver, and with bag pilling more smooth and even easier to adjust.

6.Screw type feeding system is adopted, precise in measuring, can fill material at high temperature, more suitable to high speed bag packing machine’s using.

7.Applicable to a wide range of use. Cutting method can choose flat cutting or fracture line cutting, and can match with link coding machine.

Usage:

Suitable for packing loose, non sticky powder material such as bean powder, milk powder, drug powder, bone-stronger powder, lotus powder and much more. Most commonly used in the pharmacy, food, dairy, and agriculture industries.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。