Copper alloys 銅 合 金 | Cu 107紫銅 | ECu | Red copper, atmosphere and sea water corrosion and excellent electric conductivity. Welding of red copper such as electrical copper row. | ECu | ||||

Cu 207矽青銅 | ECuSi | Silicon bronze, corrosion resistance and high strength. Welding of copper, silicon bronze and brass. | ECuSi | |||||

Cu | ECuSnB | Tin phosphor bronze, corrosion resistance and high strength. Welding of copper, silicon bronze and brass. | ECuSn-C | |||||

Cu 237 | ECuAl | Aluminum bronze, wear and corrosion and high strength. Welding or surfacing of copper alloys. | ECuAl-A2 | |||||

Aluminum alloys 鋁 合 金 | Al 109 | TAl | Pure aluminum, excellent corrosion resistance and middle strength. Welding of pure aluminum. | E1100 | ||||

Al 209 | TAlSi | Silicon aluminum, good crack resistance and wide range of usage. Welding of aluminum alloys other than aluminum magnesium alloys. | E4043 | |||||

Al 309 | TAMn | Manganese aluminum, corrosion resistance and high strength. Welding of aluminum alloys. | E3003 | |||||

Nickel alloys 鎳合金 | Ni 102 | ENi-1 | Pure nickel. Welding and surfacing of nickel and nickel to steel. | ENi-1 | ||||

Ni 207 | ENiCu-7 | Copper nickel. Welding and surfacing of copper nickel and copper nickel to steel. | ENiCu-7 | |||||

Copper alloys

銅

合

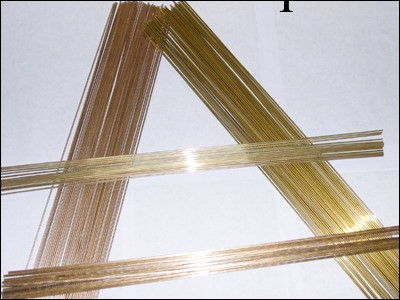

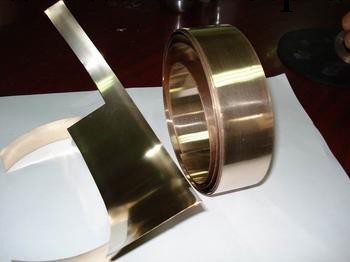

金 | S 201 紫銅焊絲 | Sn1 Si0.3Mn0.3 | Good mechanical properties and crack resistance. Gas welding and argon arc welding of red copper. | ERCu | ||||

S 211矽青銅 | Si3 Mn1 | Good mechanical properties. Argon arc welding of copper alloys and MIG brazing of steel. | ERCuSi-Al | |||||

S 212錫青銅 | Sn5 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuSn-A | |||||

S 213磷青銅焊絲 | Sn8 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuSn-C | |||||

S 214鋁青銅焊絲 | Al7.5 Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuAl-A1 | |||||

S 215鐵鋁青銅 | Al9 Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuAl-A2 | |||||

S 221黃銅焊絲 | Cu60 Sn1 Si0.3 | Melting point is about 890℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | ||||||

S 221F | Cu60 Sn1 Si 0.3 | S221 welding rod coated with flux. | ||||||

S 222鐵黃銅 | Cu58Sn0.9Si0.1 | Melting point is about 880℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | RBCuZn-C | |||||

S 222F | Cu58Sn0.9Si0.1 | S222 welding rod coated with flux. | RBCuZn-C | |||||

S 223 | Cu59 Sn0.6 | Melting point is about 900℃. Braze welding of copper, steel and cast iron. | RBCuZn-A | |||||

S 224 | Cu62 Si0.5 | Melting point is about 905℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | ||||||

Copper 銅 合 金 | S 225 | Cu48 Ni10 | Melting point is about 935℃ and high strength. Braze welding of steel, nickel and carbide alloys. | RBCuZn-D | ||||

S 225F | Cu48 Ni10 | S225 welding rod coated with flux. | RBCuZn-D | |||||

S 226 | Cu60 Sn0.3 | Melting point is about 900℃. Gas welding of brass, also braze welding of copper, steel and cast iron. | ||||||

S 227 | Cu58Sn0.9Ni0.5 | Melting point is about 880℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | RBCuZn-B | |||||

S 229 | Cu55 Ni6 Mn4 | Melting point is about 920℃, high strength. Braze welding of steel, nickel and hard carbide. | ||||||

Aluminum alloys 鋁 合 金 | S 301 | Al≥99.5 | Good ductility and corrosion resistance. Gas welding and argon arc welding of pure aluminum. | ER1100 | ||||

S 311 | Si5 Al Rem. | Corrosion resistance, wide range of usage. Gas welding and argon arc welding of aluminum alloys other than high magnesium alloys. | ER4043 | |||||

S 321 | Mn1.3 Al Rem. | Good corrosion resistance, weldability and ductility. Gas welding and argon arc welding of aluminum alloys. | ||||||

S 331 | Mg5 Mn0.4 | Corrosion resistance and high strength. Argon arc welding of aluminum alloys. | ER5183 | |||||

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。