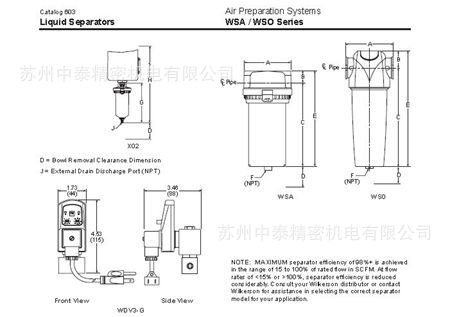

Liquid Separators WSA / WSO

Air Preparation Systems

WSA / WSO Series

Specifications

Maximum Operating (WSA) 200 PSIG (13.8 bar)

Pressure (WS0) 232 PSIG (16.0 bar)

Operating (WSA) 32° to 150°F (0° to 65.5°C)

Temperature (WS0) 35° to 176°F (1.6° to 80°C)

Pressure Differential at Rated Flow 1.0 PSID (0.07 bar)

Materials of Construction

WSA WS0

Housing Zinc Aluminum

Seals Nitrile Fluorocarbon

Liquid Separators

Our unique design combines the techniques of centrifugal

action and other mechanical separation principles

(Impingement, Separation, Laminar Flow and Stokes Law)

to remove large quantities of liquid and solid contamination.

Typical applications include water separation downstream of

aftercoolers, protection of refrigerant and heatless

regenerative desiccant dryers, downstream of air receivers,

and other liquid / gas separation duties wher the volume of

water and solids poses a real problem.

Features

n High Flow Rates

n Less than 1 PSIG Differential Pressure

n Lightweight Cast Aluminum Housing with

1" to 3" NPT Connections (WS0)

n Cast Zinc Housings with 1/4" to 1" NPT

Connections (WSA)

n External Surfaces Epoxy Painted for Maximum

Corrosion Protection

n Standard Equipped with Quick Disconnect

Bowls for Ease of Service (WSA)

n Three (3) Optional Automatic Drains Available

| Model | In / Out | Rated Flow | Approx. | Recommended |

| Number | NPT Pipe Conn. | SCFM) @ 100 PSIG* | Weight lbs. | Automatic Drain |

| WSA-02-M00** | 1/4" | 25 | 2.2 | Optional |

| WSA-02-FM0 | 1/4" | 25 | 2.2 | Internal |

| WSA-03-M00** | 3/8" | 50 | 2.6 | Optional |

| WSA-03-FM0 | 3/8" | 50 | 2.6 | Internal |

| WSA-04-M00** | 1/2" | 50 | 2.6 | Optional |

| WSA-04-FM0 | 1/2" | 50 | 2.6 | Internal |

| WSA-06-M00** | 3/4" | 100 | 6 | Optional |

| WSA-06-FM0 | 3/4" | 100 | 6 | Internal |

| WSA-08-M00** | 1" | 120 | 6 | Optional |

| WSA-08-FM0 | 1" | 120 | 6 | Internal |

| WS0-08-000B | 1" | 233 | 4.8 | X02-04-FM0 |

| WS0-0B-000B | 1-1/2" | 472 | 11.2 | WDV3-G |

| WS0-0C-000B | 2" | 742 | 11.2 | X02-04-FM0 |

| WS0-0E-000B | 3" | 1700 | 22 | WDV3-G |

| X02-04-FM0 | ||||

| WDV3-G | ||||

| X02-04-FM0 | ||||

| WDV3-G | ||||

Operation

n Air Enters the Water Separator Inlet and Turns

Into the Separator Module.

n The Inlet of the Separator Module Contains a

Set of Fixed Vanes Which the Air Must Pass

Through.

n The Vanes Force the Air to Spin Inside the

Vessel.

n The Spinning Air is Then Forced to Change

Direction as it Passes the Impinger.

n A Vortex is Created Which, Due to the

Design of the Separator Module, Narrows and

Intensifies as it Reaches the Lower Part of the

Separator Module.

n Bulk Liquid is Removed From the Airstream

Due to:

• Directional Changes of the Airstream

• Velocity Changes

• Centrifugal Action of the Vortex

n As the Vortex Reaches the Bottom of the

Module, Air is Forced Through The Center of

the Vortex.

n Aerospace Turning Vanes, Located in the Outlet

of the Separator Module, Turn an Inefficient

Corner Into a Number of More Efficient Corners.

n Turning Vanes Reduce Turbulence, Minimizing

Pressure Loss and Cost of Ownership.

n The Number of Vanes Required is Dependent

Upon the Conduit Diameter.

|

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。