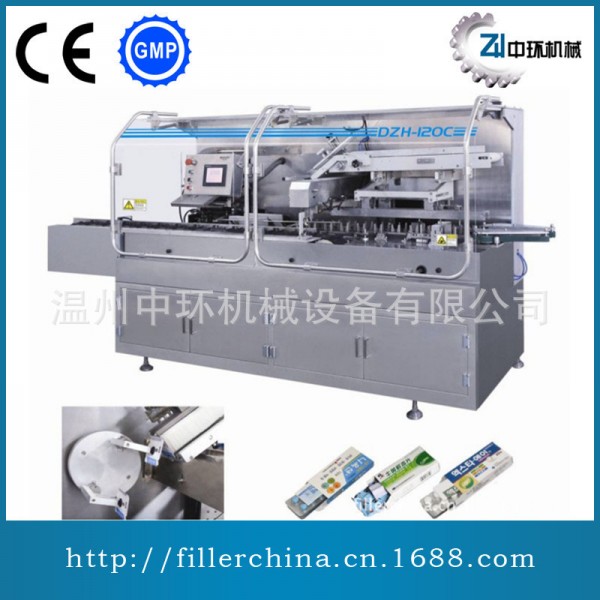

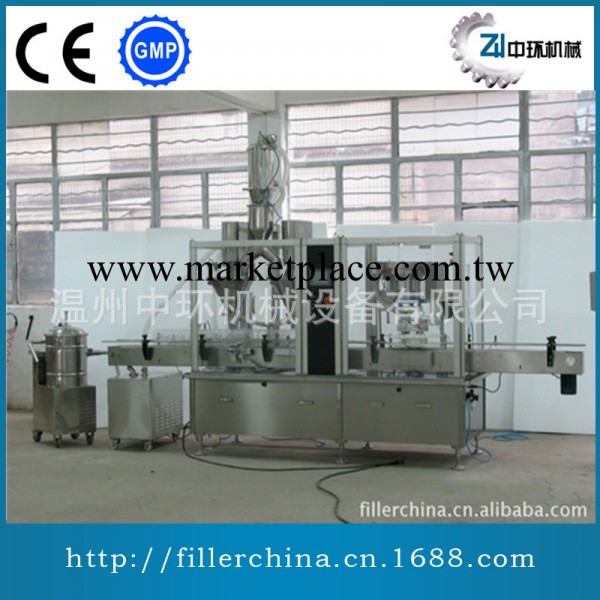

ZHGP-50型噴霧劑理瓶灌裝貼標生產聯動線

用途與簡介:

本生產線由全自動理瓶機、灌裝旋(軋)蓋機、立式貼標機組成,可全自動完成理瓶、灌裝、旋(軋)蓋、貼標打碼等工序,主要用於噴霧劑溶液的聯線生產.本生產線完全符合國傢新版GMP要求。

特點:

理瓶機系最新設計,完全取代手工,符合GMP規范。

直線式灌裝旋(軋)蓋機操作便捷、灌裝精準、可選擇不同的生產速度。

立式貼標機采用PLC及步進電機控制,貼標精準,效率高,有熱打碼。

技術參數:

適用規格15-500ml

生產能力30-45瓶/分60-80瓶/分

灌裝精度≤±1%

旋(軋)蓋率≥99%

電源220V/50Hz

功率8 kw

生產線總長7000*1000*1700mm

ZHGP-50-type spray bottle filling management joint production line labeling

Purpose and introduction:

The line consists of automatic bottle unscrambler, filling rotation (rolling) cover machine, vertical labeling machine components, can be fully automated complete management bottles, filling, rotating (rolling) cover, label coding processes, mainly used Spray the solution on the production line in this production line full compliance with the new GMP requirements.

Features:

Unscrambler Department of latest design, completely replac the manual, meet the GMP standard.

Linear filling rotation (rolling) cover machine operation easy, accurate filling, choose a different production rate.

Vertical Labeling Machine with PLC and the stepper motor control, labeling accuracy, high efficiency, hot coding.

Technical parameters:

Applicable standard 15-500ml

Production capacity of 30-45 bottles / min 60-80 bottles / min

Filling accuracy ≤ ± 1%

Rotation (rolling) cap rate ≥ 99%

Power 220V/50Hz

Power of 8 kw

Line length 7000 * 1000 * 1700mm

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。