|

型號:LL-DX800 每小時可處理廢電線700kg-1000kg

型號:LL-DX800 處理廢電線量:800kg/h |

主要設備及功能: 1、 1號切斷機—需要人手把廢電線投到切斷機內,雖有手操的短處,但操作非常簡便,產量也好。 2、 磁鐵式輸送機—是把從1號切斷機出來的廢電線移送到2號機的裝置,並在其上方設置磁鐵吸附鐵等異物。它不僅作移動作用,並且在2號粉碎機過於飽和時,會自動停止,等2號粉碎機完全消化後再正常運轉。 3、 2號粉碎機—把通過1號粉碎機變成2~3cm的廢電線粉碎並粗分離的裝置。此機器能把參在外皮上的各種異物粉碎後,與銅完全分離開來。並在其底部設有過濾網控制不同規格電線下的加工速度與產量,並且通過更換過濾網能做到細到毛髮絲粗到動力電纜的加工能力。粉碎室以油壓操動,修理與換刀片時非常容易,也是此機器的長處。 4、 鼓風機—把2號粉碎機的粉碎物利用風浪和風壓移送到選別機的移送裝置。 5、 選別機—是機械的核心,是將銅和外皮完全分離送出的一種裝置。構造雖然復雜,但操作簡便並維修方便。 6、 佈袋集塵器—是將選別機中產生的灰塵通過集塵鼓風機回收的裝置,上部設有12個過濾佈帶,材質采用進口過濾佈密不透風可有效回收灰塵保證機器周圍環境的空氣度。 7、 AIR ROCK(旋轉閥門)--位於集塵器下端,為排出內部灰塵,定時運轉的旋轉閥門。 8、 螺旋輸送機—集塵器中產生的灰塵通過AIR ROCK(旋轉閥門)回收並排出外部的裝置。 9、 控制櫃—調節所有機器,一種調控裝置,設有緊急停止、定時器等功能。原理為PLC可編控制程序控制並在機器中的每個部分都單獨排列具有可控性強穩定性強的特點。

The main equipment and function: 1, No. 1, cutting machine, need people to throw waste wire cutting machine, although the hand weaknesses, but the operation is very simple, yield. 2, the magnet conveyor is the waste wire from the 1 cutting machine out of the transferred to the device No. 2 machine, and the adsorption of iron foreign body is arranged above the magnet. It not only as a mobile role, and in 2 mill too saturated, it will automatically stop, 2 mill completely digested after normal operation. 3, No. 2, No. 1 mill pulverizer through a device for crushing waste wire 2~3cm and coarse separation. This machine can make various foreign participation in the skin after crushing, and copper completely separated. And is provided with a filtering net control processing speed of different specifications and production lines at the bottom, and by changing the filter net can do fine to coarse hair silk to the processing capacity of power cables. The crushing chamber to hydraulic operation, repair and change when the blade is very easy, but also the machine. 4 - 2, blower crusher crushing by waves and wind pressure transferred to the transfer device classification machine. 5, don't choose machine - mechanical core, is a completely separated from copper and copper sheath. Structure is complex, but simple and convenient repair. 6, bag dust collector, will choose dust generated by don't machine device is arranged on the upper part of the dust blower recovery, 12 filter cloth, filter cloth made of imported close not leak can be effectively recovered dust ensure air of machine environment. 7, AIR ROCK (rotary valve) - located in the dust collector is discharged, as the internal dust, rotary valve timing. 8, screw conveyor, dust dust produced in AIR by ROCK (rotary valve) device recovery and discharged outside. 9, control cabinet, control all the machines, a control device, equipped with an emergency stop, timer and other functions. Each part of the principle of PLC programmable control program and in the machine areseparatearrangement has the characteristics of strong stability and strong controllability.

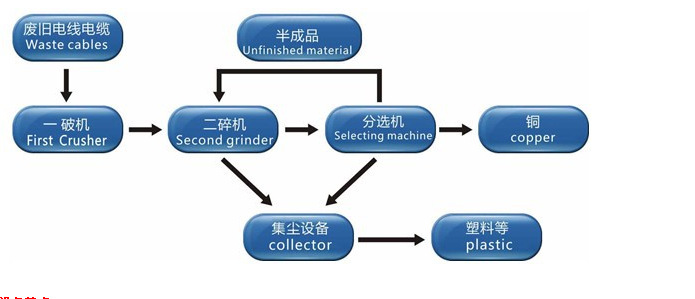

工藝流程:

| |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。