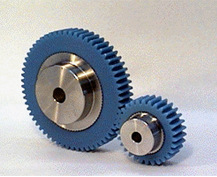

| 形狀圖 |  | 共通式樣 精度等級| JIS B 1702-1 N9 級 (*1) | 齒麵硬度HRR115 - 120 | 齒形| 全齒高齒 | 表麵處理- | 壓力角| 20° | 齒麵加工切削 | 材料| MC901 (SUS303輪轂部) | 切齒基準麵孔徑(H7) | 熱處理| 無 | 追加工可能 |

(*1) 舊 JIS B 1702 5級 | |

| | | 模數齒數形狀孔徑

A輪轂徑

B分度圓直徑

C齒頂圓直徑

D齒寬

E輪轂長

F全長

G金屬芯直徑

H容許彎曲轉矩

(kgf·m)側隙下限

(mm)側隙上限

(mm)質量

(kg)單價

按此

| | PU1-30 | | PU1-35 | | PU1-40 | | PU1-50 | | PU1-60 | | PU1-80 | | PU1.5-30 | | PU1.5-35 | | PU1.5-40 | | PU1.5-50 | | PU1.5-60 | | PU1.5-80 | | PU2-20 | | PU2-25 | | PU2-30 | | PU2-35 | | PU2-40 | | PU2-50 | | PU2-60 |

| | 1 | 30 | S1 | 8 | 20 | 30 | 32 | 10 | 10 | 20 | 20 | 0.10 | 0 | 0.34 | 0.046 | | | 1 | 35 | S1 | 8 | 25 | 35 | 37 | 10 | 10 | 20 | 25 | 0.13 | 0 | 0.34 | 0.074 | | | 1 | 40 | S1 | 10 | 25 | 40 | 42 | 10 | 10 | 20 | 28 | 0.15 | 0 | 0.34 | 0.081 | | | 1 | 50 | S1 | 10 | 30 | 50 | 52 | 10 | 10 | 20 | 34 | 0.20 | 0 | 0.34 | 0.13 | | | 1 | 60 | S1 | 10 | 40 | 60 | 62 | 10 | 10 | 20 | 45 | 0.25 | 0 | 0.36 | 0.22 | | | 1 | 80 | S1 | 10 | 40 | 80 | 82 | 10 | 10 | 20 | 45 | 0.34 | 0 | 0.36 | 0.25 | | | 1.5 | 30 | S1 | 10 | 30 | 45 | 48 | 15 | 12 | 27 | 30 | 0.35 | 0 | 0.38 | 0.15 | | | 1.5 | 35 | S1 | 10 | 33 | 52.5 | 55.5 | 15 | 12 | 27 | 36 | 0.43 | 0 | 0.40 | 0.20 | | | 1.5 | 40 | S1 | 10 | 40 | 60 | 63 | 15 | 12 | 27 | 45 | 0.51 | 0 | 0.40 | 0.31 | | | 1.5 | 50 | S1 | 12 | 40 | 75 | 78 | 15 | 12 | 27 | 45 | 0.67 | 0 | 0.40 | 0.33 | | | 1.5 | 60 | S1 | 12 | 50 | 90 | 93 | 15 | 12 | 27 | 55 | 0.83 | 0 | 0.40 | 0.51 | | | 1.5 | 80 | S1 | 12 | 60 | 120 | 123 | 15 | 12 | 27 | 85 | 1.15 | 0 | 0.42 | 1.00 | | | 2 | 20 | S1 | 10 | 22 | 40 | 44 | 20 | 14 | 34 | 22 | 0.50 | 0 | 0.42 | 0.10 | | | 2 | 25 | S1 | 10 | 30 | 50 | 54 | 20 | 14 | 34 | 30 | 0.67 | 0 | 0.42 | 0.20 | | | 2 | 30 | S1 | 10 | 35 | 60 | 64 | 20 | 14 | 34 | 35 | 0.84 | 0 | 0.44 | 0.28 | | | 2 | 35 | S1 | 12 | 40 | 70 | 74 | 20 | 14 | 34 | 45 | 1.02 | 0 | 0.44 | 0.41 | | | 2 | 40 | S1 | 15 | 55 | 80 | 84 | 20 | 14 | 34 | 60 | 1.21 | 0 | 0.44 | 0.70 | | | 2 | 50 | S1 | 15 | 60 | 100 | 104 | 20 | 14 | 34 | 65 | 1.60 | 0 | 0.44 | 0.88 | | | 2 | 60 | S1 | 15 | 60 | 120 | 124 | 20 | 14 | 34 | 85 | 1.97 | 0 | 0.46 | 1.28 |

|

|