DO NOT PLUG SENSOR WITH THE SAME ID NUMBER TO CONTROLLER

WARNING!

FOLLOW THE INSTRUCTIONS OF OPERATING THE SENSOR AND CONTROLLER, OTHERWISE THEY WILL BE DAMAGED!

Introduction:

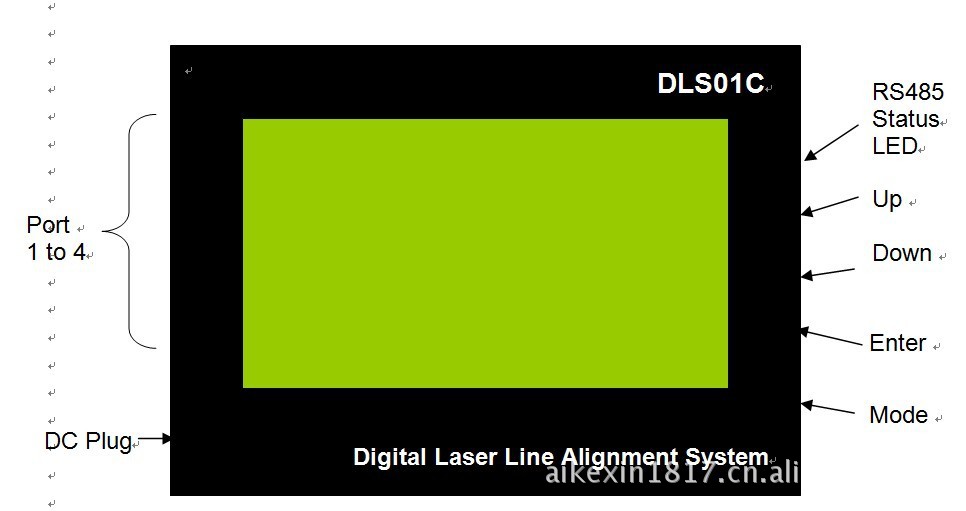

Main Controller DLS01C

DLS01 is a sophisticate laser beam alignment system which targets for low cost and high accuracy applications. The system is suitable for both laser beam and laser line positioning and alignment which stability and accuracy are the prime goals. The system employs high resolution linear position array and micro-controller based technology for stable and accuracy measurements. It allows multiple sensors connection to a centralized controller with real-time graphical interface and easy to configure measurement parameters. The measured data could be stored and analyzed by the window software that comes with the system.

Highlights:

- Stable and accurate:400 dpi position sensing array, provide upto 10um (0.0004 inch) resolutionand 40um (0.0016inch)accuracy

- Large dynamic range:Adjustable sensitivity, suitable for various ambient lighting conditions.

- Large sensing area:The linear sensor active area is 1.92 inch (48.8mm), which is ideal for measuring laser beam and line displacement.

- Real time graphical display:Dot matrix LCD controller real time display of measurements simultaneously and simple config. settings.

- Multiple sensor connectivity:Each controller interfaces upto 4 sensors module. Each module configures with individual ID.

- Fully integrated system:The controller could be connected to PC for data collection and analysis.

- Long working range:Sensors could be installed upto 200 ft. (60m) from the controller. Sensors connect to controller via industrial RS485 standard serial interface protocol.

- Alloy Housing:Provides durable and stable mounting of the sensor in rough working environments.

Laser Alignment Controller DLS01C

Single Line CCD Array Sensor DLS01S

Features:

1) Large dot matrix graphic LCD, real time light strip display on LCD

2) Long distance measurement by RS485 connection, up to 200 ft. (60m) between sensors and controller

3) Monitor upto 4 sensors at the same time

4) Graphic and real time display of laser position, easy operation of aligning of 2 or more sensors.

5) High accuracy 400 dpi resolution, with software enhancement, resolution could be up to 10um or 0.0004 inchand 40um (0.0016inch)accuracy

6) Tunable sensitivity, able to cope with different ambient light conditions.

7) Wide incident light wavelength 400 to 1000nm

8) Auto light stripe center finding function

9) Accurate laser width measurement

10)Tunable light intensity trigger level

11) Large sensitive area 48.8mm (1.92 inch), easy to capture light stripe

12)User friendly computer software, runs on OS Win2000, WinXP and Win7

Application Field:

1) Construction alignment (can work with general laser leveling equipment)

2) LED manufacturing

3) Optical laboratory

4) Laser manufacturing

5) Laser leveling manufacturing

6) Optical equipment

7) Large machine assembly

8) Beam Profile Measurements

9) M² Measurements

10) Industry process control

DLS01C Specification:

Input Voltage | 9V DC |

Operating Current (mA) | 500 |

RS485 Sensor Port | 4 port RJ11 6P6C |

Sensor support | 4 DLS01S at same time |

Display | 240128 Dot Matrix LCD |

LCD visible area (LxW in mm) | 114X64 |

Backlight | Yellow Green LED |

Color | Black |

Dimension (LxWxH in mm) | 150105X35 |

DLS01S Specification:

Input Voltage | 9V DC from DLS01C RS485 |

Operating Current (mA) | 1200 |

Input Light wavelength | 400 to 1000nm |

RS485 Sensor Port | 1 port RJ11 6P6C |

Maximum RS485 Cable Length (m) | 60 |

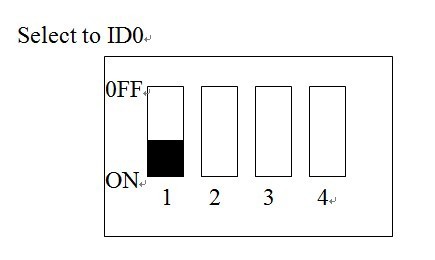

Channel Switch | 4 ways |

Light sensitivity trimmer | Round Tune |

Mounting Screw Hole | ¼” -20 standard tripod screw |

Sensing length (mm) | 48.8 |

Sensing Technique | CCD |

Maximum Sensitivity (mW) | 0.001 |

*Signal to noise SNR | 4dB |

Resolution | 768 pixel, 400 DPI |

Color | Black |

Dimension (LxWxH in mm) | 65.5X65.5X40 |

*Remark: SNR calculated in design theory.

Instruction:

DLS01C

Button Key:

Button | Function |

UP | Move cursor up |

DOWN | Move cursor down |

ENTER | Press to confirm at Menu Mode |

MODE | Scroll the mode from Measure, Menu and Power off in cycle |

Measure Mode:

ID:

Show the ID number of the sensor inside the system and relative reading.

Zero:

The zero point setting at which position. Setting zero point in Menu Mode -> Calibrate

Center:

Center position of the light stripe applied to sensor

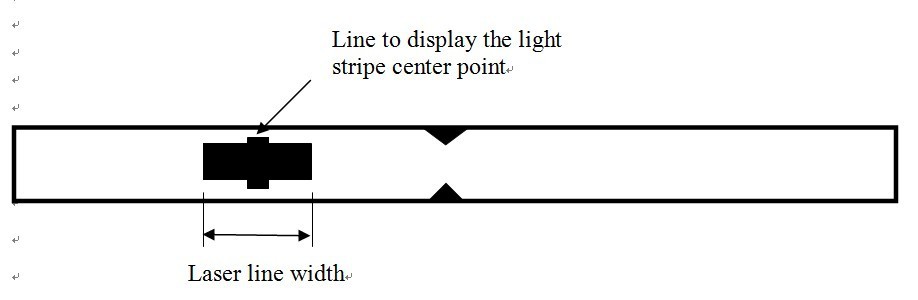

Line Width:

Light width applied on the sensor

Graphic Display of light stripe:

The LCD can display readings of the all the sensors connected to it simultaneously and real time displays the light stripe absolute position. This function is user friendly and simple for tuning or calibration.

Menu Mode:

Zoom:

4 Level digital zoom.

Press Down key to scroll from Level 1 to 4 at measure mode

In menu mode, selec the Zoom and choose level.

Tolerance:

Fast mode to verify the light stripe on 4 sensors is in straight line. If the 4 sensors in the reading with tolerance, at LCD Display right bottom corner will shows 0-1-2-3

Tolerance level has +/-0.5, +/0.1, +/-0.05 mm for selection

Resolution:

Represent running average the controller will calculate. Reading will show 10 measurement averages for setting to Level10

In menu mode, selec the Resolution and choose level.

Sensitivity:

Level 1 is lowest and 4 is highest sensitivity. This is for coarse tuning; fine tuning suggests tuning at sensor by the trimmer.

Press Up key to scroll from Level 1 to 4 at measure mode

In menu mode, selec the Sensitivity and choose level.

Backlight:

Go in menu mode to selec Backlight and press Enter to confirm on/off

Calibration:

This function can set the zero point of sensor.

1) Apply a laser dot or laser line on the sensor

2) Tune the laser center position to your target zero point

3) Press “Menu” key

4) selec “Calibrate” and press Enter

5) Make sure the laser is on zero position of sensor

6) Press Enter to /confirm/i

7) Back to Measure Mode

Reset Settings:

Scroll the number by Up or Down key, default password is 0000 and then confirm by Enter key to set to factory setting.

Instruction:

DLS01S

1) Verify the ID number of the DLS01S, one system do not allow repeat ID sensor, it may damage the controller and sensor.

2) Set the ID number to your request

3) LED will flash for normal connection

4) Ready to use

Sensor Sensitivity Fine Tuning:

1) Target the light on the sensor around the center position

2) Power on DLS01C Controller, connect sensor and controller by cable

3) Tune the “Sensitivity” at DLS01C Controller to Level 1

Clockwise: Tune down sensitivity

Anti- Clockwise: Tune higher sensitivity

4) Estimate the light line width, if it is around 2mm, and then check controller line width reading.

5) Fine tune the sensor sensitivity trimmer at DLS01S until controller line width reading is correct.

PC Communication:

1) Provide Labview VI for further development(Purchase Code: #DLS-A-0006)

2) Standard PC software support real time 4 channel light alignment and positioning(Purchase Code: #DLS-A-0006)

3) RS485 to RS232 industrial grade converter (Purchase Code: #DLS-A-0001)

Purchase Package:

4 Sensor Package (Purchase Code: #DLS-P-0001)

1 pcs DLS01C controller (Purchase Code: #DLS-C-0001)

4 pcs DLS01S line sensor (Purchase Code: #DLS-S-0001)

1 pcs 110V/220V 9V DC 2A Adapter (Purchase Code: #DLS-A-0002)

1 pcs Carrying Case (Purchase Code: #DLS-A-0003)

4 pcs 2 m RS485 6P6C Cable (Purchase Code: #DLS-A-0004)

1 pcs DLS01C mini mounting stand (Purchase Code: #DLS-A-0005)

Optional Accessories:

1 pcsDLS01A RS485- RS232Package (Purchase Code: #DLS-A-0001)

1 set DLS PC Software V1.0 (CD) (Purchase Code: #DLS-A-0006)

Headquarter:

DLS Electronics

Level 6, No221, Queens Street.

Melbourne

VIC3000

Australia

Tel: (0755)82522201

圖片介紹:

1.整體配件圖

2.主機正麵圖

3.主機接口圖

4.主機按鍵控制圖

5.配件RS232/RS-422/RS-485轉換接口

6.附件正麵圖

7.附件接口圖

NOTE:

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。