產品說明:

I. 技術描述 Technical Description

A. 主機 Machine:

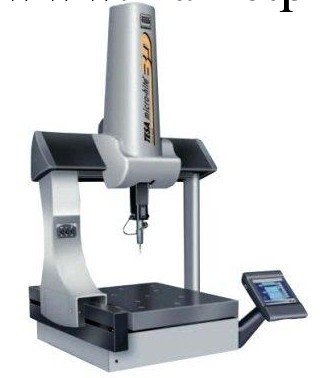

MICRO-HITE 3D測量機系統是同類產品性能價格比非常好的一款測量機器。它填補瞭傳統精密測量機器和測量機之間的空白。尤其可以滿足工業生產對高性能測量產品的要求。

該測量機的精度可以達到微米,令人感到驚奇的是操作非常簡單,即使操作者並不熟悉測量操作。該測量機所使用的測量軟件REFLEX軟件具有用戶友好的界麵操作方式,操作者在使用它幾個小時後就可以測量復雜的工件。

The MICRO-HITE 3D coordinate measuring system is the only one of its class that offers high price/performance ratio; it’s the missing link between the conventional precision measuring tool and the coordinate machine. And this product in a cell specially lay out to meet the high requirements of its manufacturer.

MICRO-HITE 3D measures parts to the micron. Surprisingly easy to operate, there’s no need of for the operator to be an expert. Owing to the interactive TESA REFLEX application software, he will be able to take complex part measurements after just a few hours of use.

· 主要特征KEY FEATURES:

① 獲得專利的TESA光學讀數頭系統

② X向橫梁采用超高剛性精密三角梁(Tricision ®)技術,通過減輕運動負荷從而提高瞭整機的性能,是保證穩定性和剛性的最佳結構設計;該領先技術受到專利保護。

③ REFLEX測量軟件,操作簡單,運行可靠

④ 符合人機工程要求的設計 – 經過深入研究獲得的結論

⑤ 22個空氣軸承保證瞭三軸無摩擦的運動

· Technical Highlight

① Patented TESA optical reading system.

② X beam has adopted the patented ultra rigid “Tricision ®” technology. This structure is the best solution to lighten main carriage’s weight and improve main carriage’s stability and rigidity, so can greatly improves CMM’s performance.

③ TESA REFLEX application software – The reference in terms of simplicity and reliability.

④ Ergonomic design – The successful conclusion of an in – depth study.

⑤ 22 air bearings to ensure a frictionless motion of the three axes.

· MICRO-HITE 3D性能指標 MICRO-HITE 3D Performance Specifications

備註:滿足環境條件要求的方法具體可參考《機房施工指南》

Note: The H3D-Installation will help customer to know how to reach the Room Requirements.

· ZMouse CONTROL控制系統

專利的Zmous取點裝置可以減少操作者在MH3D與計算機之間走動,具有加快手動測量,程序編輯及程序運行速度的作用。

The patented ZMouse pointing device eliminates operator movement between MH3D and the computer. This unique capability speeds manual measurement, program editing, and execution of pre-written programs.

B. 軟件系統 Computer System

· REFLEX測量軟件 Measuring & Inspection Software

REFLEX 是一款全三維的手動坐標測量軟件包。它同樣可替代其它的廠房中的工具如高度規,千分表和卡尺。本軟件的主要優點是它非常易於使用。菜單和使用者所需輸入的信息被減到最少。MH3D有可識別被測元素的“元素識別”功能。這軟件的策略“盡管測量”,在測量點後軟件自動構造並返回被測元素。

測量結果可用選項中等的打印機以圖形或文本的形式打印。還可提供一個內部統計分析軟件和選項將測量結果以不同格式傳向一臺外部數據集合裝置。實際球心的數據可以ASCII碼的形式通過一個系列接口傳至外部計算機以供進一步分析。

REFLEX is a full 3-D manual coordinate measuring software package. It is also a variety of other tools common on the shop floor such as height gauges, dial indicators and calipers. The key strength of the software is its amazing ease of use. Menus and input from the operator have been reduced to an absolute minimum.

MH3D incorporates a "Feature Recognition" capability which “knows” what type of feature the operator is inspecting. The strategy of this software is "Just Measure", after the points are collected the software returns a construction of the inspected feature automatically.

Measurement results can be printed on an optional printer in text or graphic form. An internal statistics package is included as well as the option to send measurement results to an external data collection device in a variety of formats. The actual ball center data can also be sent to an external computer in an ASCII file via a serial port for further analysis.

· PCMCIA 記憶卡

部件程序庫是以一個PCMCIA卡的形式提供。卡中實際存儲程序的實際數量依程序的復雜程度而不同。一般卡中有很多簡單的程序。

Part program storage is included in the form of a 2MB PCMCIA card. The actual number of programs that can be stored on the card varies depending on the complexity of the program. Typically the card should hold over many simple programs.

C. 測頭系統 Probe System

· TESASTAR觸發式測頭 TESASTAR Touch Probe

TESASTAR是觸發式測頭。

The TESASTAR is a robust touch trigger probe.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。