HG系列滾筒刮板乾燥機

HG series ROLLING SCRATCH BOARD DRIER

◎ High heat efficiency. The principle of heat transfer of the roller drier is heat conduction

and the conducting direction keeps uniform in the whole operation circle. Except heat loss of

end cover and radiation loss, all heat can be used for evaporating the damp materials on the

wall of the roller . The efficiency can reach 70-80%.

◎ Large operation elasticity and wide application. Various drying factors of the drier can

be adjusted, such as concentration of feeding liquid,thickness of material film, temperature

of heating medium,rotating speed of the roller etc.which can change drying speed of the

drier.As these factors have no interrelations each other,it brings great convenience to drying

operation.and makes it applicable to dry various materials and to meet different requirements

of production.

◎ Short drying period.The drying period of materials is normally 10 to 300 seconds,so it is

suitable for heat-sensitive materials.It also can be reducing pressure operated if it is put in

vacuum vessel.

◎ Fast drying rate.As film of materials coated on the wall of the roller is very thin.

Normal,thickness is 0.3 to 1.5 mm,plus directions of heat and matter transmitting are

identical, the vaporing strength on the surface of the film can be 20-70 kg.H2O/m2.h.

註:如客戶需要,可為客戶設計制造上部進料雙滾筒乾燥機。

Note:We can design double-cylinder with upper feeding in according with the request of customers.

◎ 熱效率高。因滾筒乾燥機傳熱機理屬熱傳導,傳熱方向在整個操作周

期中保持一致,除蓋散熱和熱輻射損失外,其餘熱量全都用於筒壁濕料膜

的蒸發上,熱效率可達70%-80%.

◎ 操作彈性大,適用性廣。可調整滾筒乾燥機的諸多乾燥因素。如進料的

濃度、塗料料膜的厚度、加熱介質的溫度、滾筒的轉動速度等,都可以改

變滾筒乾燥機的乾燥效率,且諸多因素互無牽連。這給滾筒乾燥操作帶來

很大方便,使之能適應多種物料的乾燥和不同產量的要求。

◎ 乾燥時間短。物料的乾燥周期一般隻有10-300秒,適合於熱敏性物

料。若將滾筒乾燥機設置在真空器中,則可在減壓條件下運行。

◎ 乾燥速率大。由於塗抹於筒壁的料膜很薄,一般在0.3-1.5mm,且傳

熱、傳質方向一致,料膜表麵可保持20-70kg.H2O/m2.h的蒸發強度。

◎ 滾筒乾燥機是一種內加熱傳導型轉動連續乾燥設備。旋轉的滾筒

通過其下部料槽,粘附著一定厚度的料膜,熱量通過管道輸送至滾筒

內壁,傳導到滾筒外壁,再傳導給料膜,使料膜中的濕份得到蒸發、

脫濕、使含濕分的物料得到乾燥。乾燥好的物料被裝置在滾筒表麵

的刮刀鏟離滾筒,到置於刮刀下方的螺旋輸送器,通過螺旋輸送器再

將乾物料集中、包裝。

◎ The drier is a kind of rotating continuous drying equipment with internal heating

conducting-style. Certain thickness of material film attach to the roller from material

liquid vessel under the roller.Heat is transferred to the internal wall of the cylinder

through pipes and then to the external wall and to materials film,to evaporate the

moisture in materials film so as to dry materials. Dried products are then scrasped off

by the blade fixed on the surface of the roller, fall down to the spiral conveyor under the

blade, and are conveyed, collected and packed.

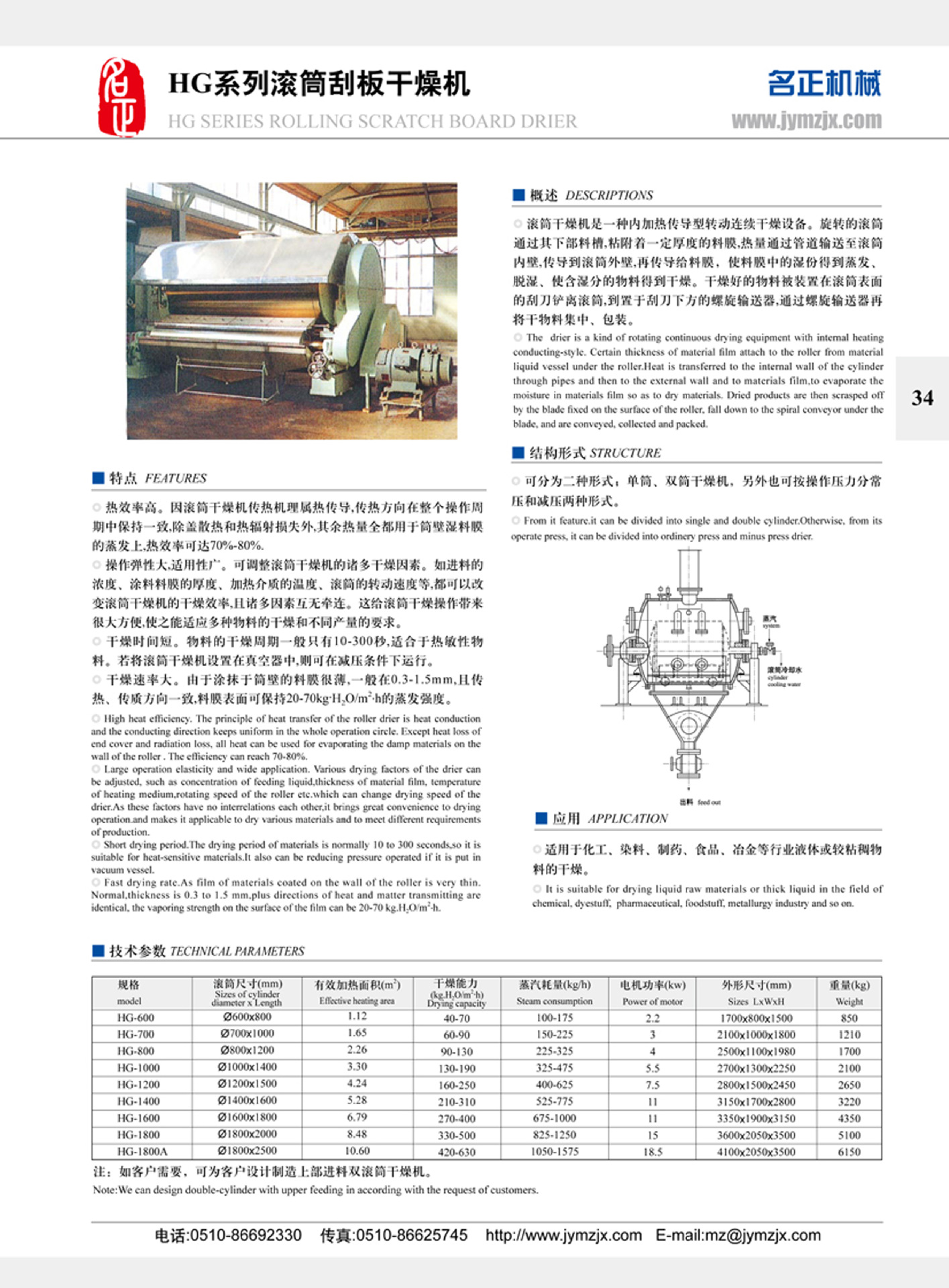

◎ 可分為二種形式;單筒、雙筒乾燥機,另外也可按操作壓力分常

壓和減壓兩種形式。

◎ From it feature.it can be divided into single and double cylinder.Otherwise, from its

operate press, it can be divided into ordinery press and minus press drier.

◎ 適用於化工、染料、制藥、食品、冶金等行業液體或較粘稠物

料的乾燥。

◎ It is suitable for drying liquid raw materials or thick liquid in the field of

chemical, dyestuff, pharmaceutical, foodstuff, metallurgy industry and so on.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。