| 品名:哈氏合金 | 牌號:C-276 | 產地:美國 |

| 鎳含量:57(%) | 雜質含量:合格(%) | 粒度:合格(目) |

| Mo:16 | Cr:16 | Ni:57 |

現貨供應哈氏合金C-276(美國SMC)

選特材,要專業。

鈦、鎳基合金、特種不銹鋼專業供應商--天津鑫海潤達鋼鐵貿易有限公司

C-276全稱為HastelloyC-276(哈氏合金)

一、耐蝕性能

哈氏C-276合是一種含鎢的鎳-鉻-鉬合金,極低的矽碳含量,被認為是萬能的抗腐蝕合金。主要耐濕氯、各種氧化性氯化物、氯化鹽溶液、硫酸與氧化性鹽,在低溫與中溫鹽酸中均有很好的耐蝕性能。因此,近三十年以來、在苛刻的腐蝕環境中,如化工、石油化工、煙氣脫硫、紙漿和造紙、環保等工業領域有著相當廣泛的應用。

該合金具有以下特性:①在氧化和還原兩氛圍狀態中,對大多數腐蝕介質具有優異的耐腐蝕性能。②有出色的耐點蝕、縫隙腐蝕和應力腐蝕性能。較高的Mo、Cr含量使合金能夠耐氯離子腐蝕,W元素進一步提高瞭耐蝕性。同時,ng>哈氏合金C-276 ng>合金是僅有的幾種耐潮濕氯氣、次氯酸鹽及二氧化氯溶液腐蝕的材料之一,對高濃度的氯化鹽溶液如氯化鐵和氯化銅有顯著的耐蝕性。適用於各種濃度的硫酸溶液,是少數幾種能應用於熱濃硫酸溶液的材料之一。

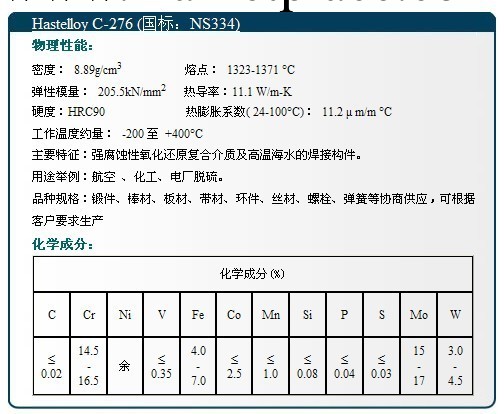

哈氏C-276合金的物理性能如下所示:

材料成分:57Ni-16Cr-16Mo-5Fe-4W-2.5Co*-1Mn*-0.35V*-0.08Si*-0.01C**為最大a餘量

執行標準:UNS N10276,ASTM B575,ASME SB575,DIN/EN 2.4819

密 度:8.90g/cm3

抗拉強度:σb≥730Mpa,延伸率:δ≥40%,硬度:HRB≤100。

哈氏C-276合金熱成形是在1150℃時立即退火,並以水急冷。對哈氏C-276合金進行冷變形加工會使其強度增加。

哈氏C-276合金和普通奧氏體不銹鋼有相似的成形性能。但由於其比普通奧氏體不銹鋼的強度要大,所以,在冷成形加工過程中會有更大應力。此外,這種材料的加工硬化速度比普通不銹鋼快得多,因此在有廣泛冷成形加工過程中,要采取中途退火處理。

四、焊接及熱處理

C-276合金的焊接性能和普通奧氏體不銹鋼相似,在使用一種焊接方法對C-276焊接之前,必須要采取措施以使焊縫及熱影響區的抗腐蝕性能下降最小,如鎢極氣體保護焊(GTAW)、金屬極氣體保護焊(GMAW)、埋弧焊或其他一些可以使焊縫及熱影響區抗腐蝕性能下降最小的焊接方法。但對於諸如氧炔焊等有可能增加材料焊縫及熱影響區含碳量或含矽量的焊接方法是不適合采用的。

關於焊接接頭形式的選擇,可以參照ASME鍋爐與壓力容器規范對哈氏C-276合金焊接接頭的成功經驗。

焊接坡口最好采用機械加工的方法,但是機械加工會帶來加工硬化,所以對機械加工的坡口處進行焊接前打磨是必要的。

焊接時要采用適宜的熱輸入速度,以防止熱裂紋的產生。

在絕大多數腐蝕環境下,哈氏C-276合金都能以焊接件的形式應用。但在十分苛刻的環境中,C-276材料及焊接件要進行固溶熱處理以獲得最好的抗腐蝕性能。

哈氏C-276合金材料固溶熱處理包括兩個過程:(1)在1040℃~1150℃加熱;(2)在兩分鐘之內快速冷卻至黑色狀態(400℃左右),這樣處理後的材料有很好的耐蝕性能。因此僅對哈氏C-ng>276合金 ng> 進行消應力熱處理是無效的。在熱處理之前要清理合金表麵的油污等可能在熱處理過程中產生碳元素的一切污垢。

哈氏C-276合金表麵在焊接或熱處理時會產生氧化物,使合金中的Cr含量降低,影響耐蝕性能,所以要對其進行表麵清理。可以使用不銹鋼絲刷或砂輪,接下來浸入適當比例硝酸和氫氟酸的混合液中酸洗,最後用清水沖洗乾凈。

五、應用領域

石油化工設備、熱交換器、煙氣脫硫設備、流體化工泵、氟化工等。

HastelloyC - 276 (OUTOKUMPU) - tianjin xin sea embellish of iron and steel trade co., LTD

C - 276 all called HastelloyC - 276 (ha's alloy)

A, corrosion resistant performance

Ha's C - 276 joint is a kind of tungstenic nickel - chromium - molybdenum alloy, extremely low silicon carbon content, is considered to be everything corrosion resistant alloy. The main resistance to wet chlorine, all kinds of oxidizing chloride, LvHuaYan solution, acid and oxidizing salt, in low temperature and medium temperature in hydrochloric acid are very good corrosion resistant performance. Therefore, nearly 30 years, in the harsh corrosive environment, such as chemical industry, petroleum chemical industry, flue gas desulfurization, pulp and paper, environmental protection and other industrial fields has a wide application.

This alloy has the following characteristics: (1) in the oxidation and reduction two atmosphere condition, for the majority of corrosion medium have excellent corrosion resistance. (2) have excellent resistance to spot corrosion, crevice corrosion and stress corrosion resistance. Higher Mo, Cr content make alloy can resistance to chlorine ion corrosion, W element to enhance the corrosion resistance. At the same time, ha'sng>C - 276 ng>alloy is only several resistance to wet chlorine, hypochlorous acid salt and chlorine dioxide solution corrosion materials of high levels of LvHuaYan solution such as ferric chloride and copper chloride have significant corrosion resistance. Applicable to various concentration of sulfuric acid solution, is a few can be applied to hot concentrated sulfuric acid solution of one of the material.

Second, the physical properties

Ha's C - 276 the physical properties of the alloy shown below:

Material composition: 57 ni - 16 cr - 16 mo - 5 fe - 4 w - 2.5 Co * - 1 mn * 0.35 V * 0.08 Si * 0.01 C * * for maximum a margin

Execution standard: UNS N10276, ASTM B575, ASME SB575, DIN/EN 2.4819

Close degree: 8.90 g/cm3

C - 276 all called HastelloyC - 276 (ha's alloy)

A, corrosion resistant performance

Ha's C - 276 joint is a kind of tungstenic nickel - chromium - molybdenum alloy, extremely low silicon carbon content, is considered to be everything corrosion resistant alloy. The main resistance to wet chlorine, all kinds of oxidizing chloride, LvHuaYan solution, acid and oxidizing salt, in low temperature and medium temperature in hydrochloric acid are very good corrosion resistant performance. Therefore, nearly 30 years, in the harsh corrosive environment, such as chemical industry, petroleum chemical industry, flue gas desulfurization, pulp and paper, environmental protection and other industrial fields has a wide application.

This alloy has the following characteristics: (1) in the oxidation and reduction two atmosphere condition, for the majority of corrosion medium have excellent corrosion resistance. (2) have excellent resistance to spot corrosion, crevice corrosion and stress corrosion resistance. Higher Mo, Cr content make alloy can resistance to chlorine ion corrosion, W element to enhance the corrosion resistance. At the same time, ha's

Second, the physical properties

Ha's C - 276 the physical properties of the alloy shown below:

Material composition: 57 ni - 16 cr - 16 mo - 5 fe - 4 w - 2.5 Co * - 1 mn * 0.35 V * 0.08 Si * 0.01 C * * for maximum a margin

Execution standard: UNS N10276, ASTM B575, ASME SB575, DIN/EN 2.4819

Close degree: 8.90 g/cm3

Three, mechanical performance

Tensile strength: σ b was 730 mpa, elongation: δ was 40%, hardness: HRB acuities were 100.

Ha's C - 276 alloy hot forming is 1150 ℃ in immediately when annealing, and water quenching. For harry's C - 276 alloy for cold deformation processing will make its strength increase.

Ha's C - 276 alloy and ordinary austenitic stainless steel has similar forming performance. But because of its better than ordinary austenitic stainless steel strength, so, in cold forming process will have more stress. In addition, this kind of material of work hardening faster than ordinary stainless steel much faster, so in a wide cold forming process, should take midway annealing treatment.

Four, welding and heat treatment

C - 276 alloy welding performance and ordinary austenitic stainless steel similar, in the use of a welding method of C - 276 before welding, must take measures to the weld seam and heat affected OuDeKang corrosion performance decline minimum, such as tungsten electrode gas shielded welding (GTAW), metal arc welding (GMAW) gas protection, submerged arc welding or some other can the weld seam and heat affected zone corrosion resistance dro the smallest welding method. But for such as oxy-acetylene welding, etc may increase material welding seam and heat affected zone carbon content or content of silicon welding method is not suitable for the use.

on the choice of the form of welded joint, can consult the ASME boiler and pressure vessel code for harry's C - 276 alloy welding joint success experience.

Welding groove had better use mechanical processing method, but mechanical processing will bring work hardening, so the machining groove in grinding is necessary before welding.

Welding should be used when appropriate heat input speed, in order to prevent the generation of hot crack.

In the vast majority of corrosive environment, ha's C - 276 alloy with the form of "application. But in the very harsh environment, C - 276 materials and weldments must carry on the solution heat treatment to obtain the best corrosion resistance.

Ha's C - 276 alloy welding can choose their own for welding material or filler metal. Such as the requirements in the ha's C - 276 alloy weld adding some ingredients, like other nickel base alloy or stainless steel, and the weld will be exposed to the corrosion milieu, then, welding used electrode or wire is require and base metal corrosion quite performance.

Ha's C - 276 alloy material solution heat treatment includes two processes: (1) in 1040 ℃ ~ 1150 ℃ heating; (2) in two minutes fast cooling to black state (400 ℃ or so), this process after the material has good corrosion resistance. Therefore only the ha's C - 276 alloy elimination stress heat treatment is invalid. In the heat treatment before cleaning alloy surface pollution, may in the heat treatment process to produce carbon element in all the dirt.

Ha's C - 276 alloy surface in welding or heat treatment can produce the oxide, make the alloy of Cr content reduce, affects the corrosion resistant performance, so want to carry on the surface cleaning. Can use stainless steel wire brush or grinding wheel, and then dip appropriate proportion of nitric acid and hydrofluoric acid in the mixture, and finally rinse clean with water.

Five, application field

Petrochemical equipment, heat exchanger, flue gas desulfurization equipment, fluid chemical pump, fluorine chemical industry, etc

天津鑫海潤達鋼鐵貿易有限公司為Great Group下屬企業單位,常年銷售瑞典OUTOKUMPU(奧托坤普)、AVESTA(阿威斯塔)、美國哈氏合金、美國SMC、德國蒂森克虜伯VDM、日本新日鐵、神戶制鋼、住友金屬、日本冶金、日本大同等國際知名鋼廠生產的鈦及鈦合金、鎳基合金、超級奧氏體不銹鋼、雙相鋼等特種合金材料。

無論您需求多少,我司盡可能滿足貴司的需求,歡迎來電咨詢。

選特材,要專業。鈦、鎳基合金、特種不銹鋼現貨供應商---天津鑫海潤達鋼鐵貿易有限公司

新手教學

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。