| 品名:高強耐磨復雜銅合金 | 牌號:ZA27-2,/ZA35/ZA10-5/ZCuAl10Fe3/ZQSn5-5-5/ZQSn6-6-3 | 產地:蕪湖 |

| 銅含量:90(%) | 雜質含量:0.01(%) | 粒度:1(目) |

| 軟化溫度:1000(℃) | 導電率:1(%IACS) | 硬度:500(HRB) |

| 序號 | 合金牌號 | 鑄造方式 | 力學性能≥ | |||

| 抗拉強度бb/Mpa | 屈服強度б0.2/Mpa | 伸長率δ5/% | 佈氏硬度(HB) | |||

| 1 | ZCuSn3Zn8Pb6Ni1 | S | 175 | 8 | 590 | |

| J | 215 | 10 | 685 | |||

| 2 | ZCuSn3Zn11Pb4 | S | 175 | 8 | 590 | |

| J | 215 | 10 | 590 | |||

| 3 | ZCu5Pb5Zn5 | S、J | 200 | 90 | 13 | 590 |

| Li、La | 250 | 100 | 13 | 635 | ||

| 4 | ZCu10P1 | S | 220 | 130 | 3 | 785 |

| J | 310 | 170 | 2 | 885 | ||

| Li | 330 | 170 | 4 | 885 | ||

| La | 360 | 170 | 6 | 885 | ||

| 5 | ZCuSn10Pb5 | S | 195 | 10 | 685 | |

| J | 245 | 10 | 685 | |||

| 6 | ZCuSn10Zn2 | S | 240 | 120 | 12 | 685 |

| J | 245 | 140 | 6 | 785 | ||

| Li、La | 270 | 140 | 7 | 785 | ||

| 7 | ZCuPb10Sn10 | S | 180 | 80 | 7 | 635 |

| J | 220 | 140 | 5 | 685 | ||

| Li、La | 220 | 110 | 6 | 685 | ||

| 8 | ZCuPb15Sn8 | S | 170 | 80 | 5 | 590 |

| J | 200 | 100 | 6 | 635 | ||

| Li、La | 220 | 100 | 8 | 635 | ||

| 9 | ZCuPb17Sn4Zn4 | S | 150 | 5 | 540 | |

| J | 175 | 7 | 590 | |||

| 10 | ZCuPb20Sn5 | S | 150 | 60 | 5 | 440 |

| J | 150 | 70 | 6 | 540 | ||

| La | 180 | 80 | 7 | 540 | ||

| 11 | ZCuPb30 | J | 245 | |||

| 12 | ZCuAl18Mn13Fe3 | S | 600 | 270 | 15 | 1570 |

| J | 650 | 280 | 10 | 1665 | ||

| 13 | ZCuAl8Mn13Fe3Ni2 | S | 645 | 280 | 20 | 1570 |

| J | 670 | 310 | 18 | 1665 | ||

| 14 | ZCuAl19Mn2 | S | 390 | 20 | 835 | |

| J | 440 | 20 | 930 | |||

| 15 | ZCuAl9Fe4Ni4Mn2 | S | 630 | 250 | 16 | 1570 |

| 16 | ZCuAl10Fe3 | S | 490 | 180 | 13 | 980 |

| J | 540 | 200 | 15 | 1080 | ||

| Li、La | 540 | 200 | 15 | 1080 | ||

| 17 | ZCuAl10Fe3Mn2 | S | 490 | 15 | 1080 | |

| J | 540 | 20 | 1175 | |||

| 18 | ZCuZn38 | S | 295 | 30 | 590 | |

| J | 295 | 30 | 685 | |||

| 19 | ZCuZn25Al6Fe3Mn3 | S | 725 | 380 | 10 | 1570 |

| J | 740 | 400 | 7 | 1655 | ||

| Li、La | 740 | 400 | 7 | 1665 | ||

| 20 | ZCuZn26Al4FeMn3 | S | 600 | 300 | 18 | 1175 |

| J | 600 | 300 | 18 | 1275 | ||

| Li、La | 600 | 600 | 18 | 1275 | ||

| 21 | ZCuZn31Al2 | S | 295 | 12 | 785 | |

| J | 390 | 15 | 885 | |||

| 22 | ZCuZn35Al2Mn2Fe1 | S | 450 | 170 | 20 | 980 |

| J | 200 | 200 | 18 | 1080 | ||

| Li、La | 200 | 200 | 18 | 1080 | ||

| 23 | ZCuZn38Mn2Pb2 | S | 245 | 10 | 685 | |

| J | 345 | 18 | 785 | |||

| 24 | ZCuZn40Mn2 | S | 345 | 20 | 785 | |

| J | 390 | 25 | 885 | |||

| 25 | ZCuZn40Mn3Fe1 | S | 440 | 18 | 980 | |

| J | 490 | 15 | 1080 | |||

| 26 | ZCuZn33Pb2 | S | 180 | 70 | 12 | 490 |

| 27 | ZCuZn40Pb2 | S | 220 | 15 | 785 | |

| J | 280 | 120 | 20 | 885 | ||

| 28 | ZCuZn16Si4 | S | 345 | 15 | 885 | |

| J | 390 | 20 | 980 | |||

| 註:1、佈氏硬度試驗,力的單位為牛頓(N); | ||||||

| 2、鑄造方式代號表示涵義:S-砂型鑄造,J-金屬型鑄造,La-連續鑄造,Li-離心鑄造; | ||||||

| 3、向鑄造工作的前輩們致敬! | ||||||

供應國標、美標鋅基合金、銅合金鑄造件:ZA11 ZA27-2 ZA30 ZA33 ZA45 QZN10-5 SJ4 SJ5 ZCuSn3Zn8Pb6Ni1 ZCuSn3Zn11Pb4 ZCuSn5Pb5Zn5 ZCuSn10Pb1 ZCuSn10Pb5 ZCuSn10Zn2 ZCuPb15Sn8 ZCuPb17Sn4Zn4 ZCuPb20Sn5 ZCuPb30 ZCuAl8Mn13Fe3 ZCuAl8Mn13Fe3Ni2 ZCuAl9Mn2 ZCuAl9Fe4Ni4Mn2 ZCuAl11Fe3 ZCuAl10Fe3Mn2 ZCuZn38 ZCuZn25Al6Fe3Mn3 ZCuZn26Al4Fe3Mn3 ZCuZn31Al2 ZCuZn35Al2Mn2Fe1 ZCuZn38Mn2Pb2 ZCuZn40Mn2 ZCuZn40Mn3Fe1 ZCuZn40Pb2 ZCuZn16Si4 ZCuSn3Zn8Pb6Ni1 ZCuSn3Zn11Pb4 ZCuSn5Pb5Zn5 ZCuSn10Pb1 ZCuSn10Pb5 ZCuSn10Zn2 ZCuPb10Sn10 ZCuPb15Sn8 ZCuPb17Sn4Zn4 ZCuPb20Sn5 ZCuPb30 ZCuAl8Mn13Fe3 ZCuAl18Mn13Fe3Ni2 ZCuAl9Mn2 ZCuAl9FeNi4Mn2 ZCuAl10Fe3 ZCuAl10Fe3Mn2 ZCuZn38 ZCuZn25Al6Fe3Mn3 ZCuZn26Al4Fe3Mn3 ZCuZn31Al2 ZCuZn35Al2Mn2Fe1 ZCuZn38Mn2Pb2 ZCuZn40Mn2 ZCuZn40Mn3Fe1 ZCuZn33Pb2 ZCuZn40Pb2 ZCuZn16Si4

產品采用金屬模、砂型、離心等鑄造方式。

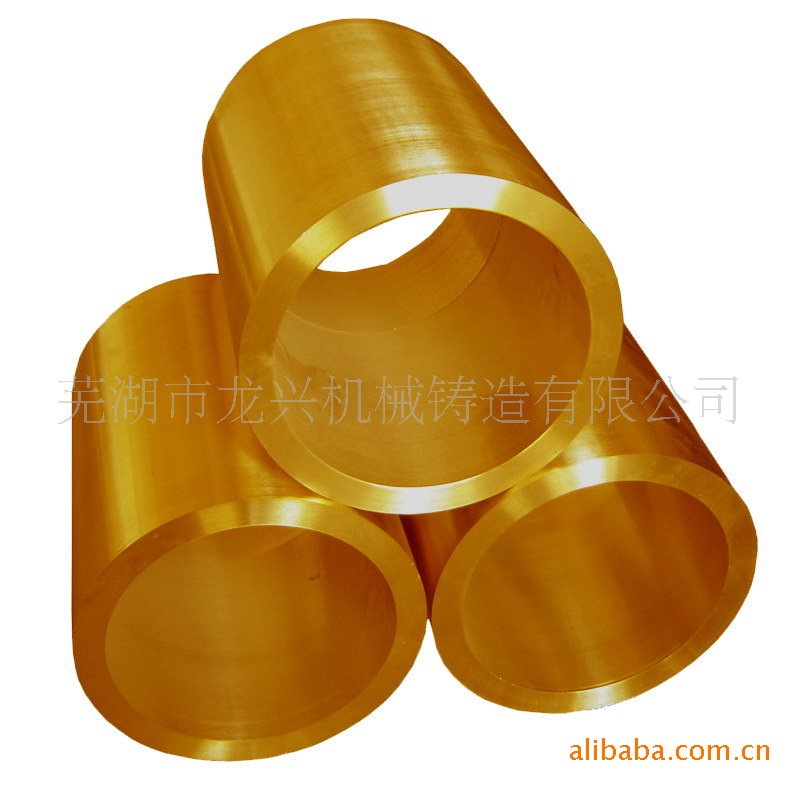

產品有:軸套、蝸輪、螺母、滑塊、耐磨板、導向板、軸瓦、殼體等。

合金牌號 | 抗拉強度MPa | 延伸率% | 硬度HBS | 比重g/cm3 |

ZZnAl4 | 245 | 3-6 | 70-90 | 6.6 |

ZZnAl4-0.5 | 275 | 2-5 | 85-100 | 6.68 |

ZZnAl4-1 | 275 | 2-5 | 85-105 | 6.7 |

ZZnAl9-1.5 | 294 | 2 | 100-110 | 6.2 |

ZZnAl10-5 | 314 | 3 | 105-115 | 6.3 |

Y41 | 275 | 5 | 85-105 | 6.7 |

Y40 | 245 | 3 | 70-90 | 6.6 |

ZA8 | 365 | 2 | 90-100 | 6.3 |

ZA12 | 392 | 3 | 95-105 | 6.0 |

ZA27-2 | 420 | 6 | 100-120 | 4.85 |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。

.jpg)