| 濾料類型:陶粒 | 適用對象:水 | 用途:水過濾 |

| 性能:耐酸,耐堿,耐高溫,耐低溫,防火,防水,防靜電 | 類型:高效 | 品牌:滿堂紅 |

| 吸附率:97.5(%) | 抗壓力:650(kgf) | 密度:1.9(g/cm3) |

| 孔隙率:53(%) | 磨損率:0.02% | 硬度:7.5 |

| 化學成分:sio2 | 鹽酸可溶率:0.02(%) |

生產2-4mm濾池污水處理用陶粒砂

陶粒簡介:

陶粒濾料采用優質陶土,粘土,粘溶劑等經團磨、篩分、煅燒加工而成,呈黑褐色球狀,具有表麵堅硬、內部多微孔、孔隙率高等特點。以好氧活性污泥作為接種,進水兩周即可達到曝氣生物濾池的處理效果。

陶粒分類及特點為:

(1)、生物陶粒濾料

生物陶粒濾料是一種顆粒狀水處理濾料,該濾料具有機械強度高、耐沖刷、耐磨損、理化性能穩定等特點,同時由於其微孔豐富、表麵粗糙、比表麵積大,使用壽命長、耐腐蝕、吸附性能好、顆粒均勻、密度適宜、不易結板、流失量小,因此截污能力強、掛膜效率高,又利於微生物生長、繁殖、可有效去除水中有機物,懸浮及淡磷等。

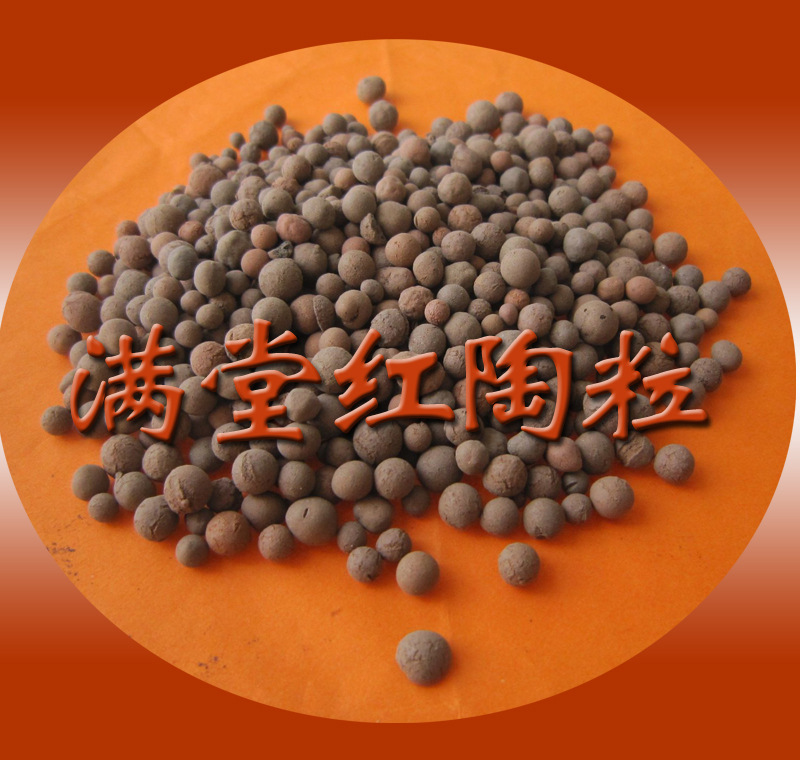

陶粒的外觀特征大部分呈圓形或橢圓形球體,但也有一些仿碎石陶粒不是圓形或橢圓形球體,而呈不規則碎石狀。陶粒形狀因工藝不同而各異。它的表麵是一層堅硬的外殼,這層外殼呈陶質或釉質,具有隔水保氣作用,並且賦予陶粒較高的強度。陶粒的粒徑一般為5~20㎜最大的粒徑為25㎜。陶粒一般用來取代混凝土中的碎石和卵石。

陶粒的外觀顏色因所采用的原料和工藝不同而各異。焙燒陶粒的顏色大多為暗紅色、赭紅色,也有一些特殊品種為灰黃色、灰黑色、灰白色、青灰色等。因為生產陶粒的原料很多,陶粒的品種也很多,因而顏色也就很多。免燒陶粒因所用固體廢棄物不同,顏色各異,一般為灰黑色,表麵沒有光澤度,不如焙燒陶粒光滑。

物理、化學性能分析

分析項目 | 測試數據 | 分析項目 | 測試數據 |

密度 | 1.8-2.0g/cm3 | 比表麵積 | 3980m2/m3 |

容重 | 1.0-1.2g/cm3 | 正常濾速 | 20+30m/h |

磨損率 | ≤0.31% | 其它性能,均不超標 | |

孔隙率 | 53% | ||

輕質性是陶粒許多優良性能中最重要的一點,也是它能夠取代重質砂石的主要原因。陶粒的內部結構特征呈細密蜂窩狀微孔。這些微孔都是封閉型的,而不是連通型的。它是由於氣體被包裹進殼內而形成的,這是陶粒質輕的主要原因。

陶粒的細小顆粒部分稱為陶砂。在陶粒中有許多小於5㎜的細顆粒,在生產中用篩分機將這部分細小顆粒篩分出來,習慣上稱之為陶砂。陶砂的密度略高,化學和熱穩定性好。

陶砂主要用於代替天然河砂或山砂配制輕集料混凝土、輕質砂漿,也可作耐酸、耐熱混凝土細集料。主要品種有黏土陶砂頁巖陶砂和粉煤灰陶砂等。使用陶砂的目的也是為降低建築物自重。陶砂也可用於無土栽培和工業過濾。

生物陶粒濾料適用於:

(1)工業污水和生活引用水處理、工業循環水處理:

(2)污(廢)水、中水深度處理及回用處理,遊泳池水處理:

(3)給水中的微污染物(氨氮)處理,高純制備預處理系統;

(4)軋鋼、連鑄等生產過程中的循環水處理;

(5)生物曝氣池的生物載體及含油廢水。

常用規格:0.5-32mm

物理、化學性能分析

分析項目 | 測試數據 | 分析項目 | 測試數據 |

密度 | 1.8-2.0g/cm3 | 比表麵積 | 3980m2/m3 |

容重 | 0.8-1.0g/cm3 | 正常濾速 | 20-30m/n |

磨損率 | ≤0.11% | 其它性能,均不超標 | |

孔隙率 | 53% | ||

(2)、輕質頁巖陶粒濾料

外觀:紅褐色或黑灰色顆粒狀

特點:1、比重小、機械強度高、耐沖耐磨損、節省能耗,生物穩定性、化學穩定性及熱力學穩定性好。2、由於表麵粗糙,微孔結構豐富、比表麵積,因此截污能力強,掛膜效率高,利於微生物生長繁殖,生物量高。3、抗沖擊負荷能力強,耐低溫,易掛膜,啟動快,反沖洗能耗低 。用途:酸、中、堿性水的過濾,是理想的水處理產品

輕質陶粒濾料是一種新型的生物膜載體填料,具有質輕,比表麵積大,吸附能力強等優點。適用於各種型式的濾池濾罐。與石英砂相比,比表麵積為同體積石英砂的2-3倍,孔隙率為石英砂的1.3-2.0倍。與砂濾比較,平均濾速高(20-25m/h),產水量大,過濾周期長,沖洗頻率小,沖洗強度低。

頁巖陶粒又稱膨脹頁巖。以黏土質頁巖、板巖等經破碎、篩分,或粉磨後成球,燒脹而成的粒徑在5㎜以上的輕粗集料為頁巖陶粒。頁巖陶粒按工藝方法分為:經破碎、篩分、燒脹而成的普通型頁巖陶粒;經粉磨、成球、燒脹而成的圓球形頁巖陶粒。適用於保溫用的、結構保溫用的輕集料混凝土,也可用於結構用的輕集料混凝土。目前頁巖陶粒的主要用途是生產輕集料混凝土小型空心砌塊和輕質隔墻板。

分析項目 | 測試數據 | 分析項目 | 測試數據 |

比重 | 1.6g/cm3 | 鹽酸可溶率 | 2.8% |

容重 | 0.8g/cm3 | SiO2 | 65% |

磨損率 | 1.8% | Al2O3 | 18-22% |

孔隙率 | 56% | Fe2O3 | 6-8% |

比表麵積 | >980cm2/g | 其它金屬含量均不超標 | |

常用規格:0.5-1mm 1-2mm 2-3mm 2-4mm 3-5mm 4-8mm 5-10mm 10-20mm 40-80mm

Ceramsite introduction:

Ceramsite filter material is made of high quality clay, clay, such as adhesive solvent by group grinding, screening and calcined processing and become, the dark brown ball, with a hard surface, internal microporous, porosity higher characteristic. In aerobic activated sludge as inoculation, water two weeks can achieve a aeration biological filter processing effect.

Ceramsite classification and features:

(1), biological ceramsite filter material

Biological ceramsite filter material is a kind of granular water treatment filter material, this filter material with high mechanical strength, resistance to erosion and wear resistance, physical and chemical stable performance, etc, and at the same time, because of its microporous rich, surface roughness, specific surface area is big, long service life, resistant to corrosion, adsorption performance is good, suitable for uniform particles, density, it is hard to form board, loss is small, so cut corrupt capability is strong, hang membrane efficiency is high, and for the microbial growth, reproduction, can effectively remove organic matter in water, suspended and light phosphorus, etc.

Ceramsite appearance characteristics most assumes the circular or elliptic sphere, but there are also some imitation rock ceramsite not round or oval ball, and irregular rock type. Ceramsite shape varies because of the process. Its surface is a layer of hard shell, this layer of shell is ceramic or enamel, with every gas and water conservation function, and give ceramsite high strength. Ceramsite size is generally five to twenty ㎜ maximum particle size of 25 ㎜. Ceramsite concrete are commonly used to replace the gravel and pebbles.

Ceramsite appearance color for the raw material and process varies. The color of the ceramsite calcined mostly dark red, ember, also have some special varieties for lark, to black, grey, green, etc. Because production ceramsite raw material a lot, ceramsite breed is very much also, and also a lot of color. Avoid burning ceramsite used for solid waste is different, different color, is generally to black, the surface gloss, not as roasting ceramsite smooth.

Physical and chemical properties analysis

Analyze project test data analysis project test data

Density of 1.8-2.0 g/cm3 specific surface area of 3980 m2 / m3

Bulk density of 1.0-1.2 g/cm3 normal filter speed twenty - 30 m/h

Wear rate 0.31% or less other properties, are not overweight

Pore rate 53%

Light sex is ceramsite many good performance in the most important thing, but also it can replace the main reason for the heavy sand. Ceramsite internal structure characteristics is fine cellular micro hole. The micro hole are enclosed, not connected type. It is due to gas wrapped his shell and form, this is the main reason for the light ceramsite.

Ceramsite tiny particles called ceramic sand part. Many of the ceramsite ㎜ less than 5 of fine particles in production by sieving machine will be part of this tiny particle screening out, traditionally called ceramic sand. Ceramic sand density slightly tall, chemical and thermal stability.

Ceramic sand is mainly used to replace natural river sand or mountain sand preparation of lightweight aggregate concrete, light mortar, also can make acid, heat-resistant concrete fine aggregate. Main varieties of clay ceramic sand shale ceramic sand and coal grey pottery sand, etc. The purpose of the use of ceramic sand is also to reduce weight buildings. Ceramic sand can also be used to soilless culture and industrial filter.

Biological ceramsite filter material suitable for:

(1) industrial wastewater and drinking water treatment, industrial circulating water treatment:

(2) and (waste) water, water depth treatment and reuse treatment, swimming pool water treatment:

(3) the water micropollutants (ammonia nitrogen) processing, high purity preparation preprocessing system;

(4) steel rolling, continuous casting and other production process of circulating water treatment;

(5) biological aeration tank biological carrier and oily waste water.

Commonly used specifications: 0.5-32 mm

Physical and chemical properties analysis

Analyze project test data analysis project test data

Density of 1.8-2.0 g/cm3 specific surface area of 3980 m2 / m3

Bulk density of 0.8-1.0 g/cm3 normal filter speed twenty - 30 m/n

Wear rate 0.11% or less other properties, are not overweight

Pore rate 53%

(2), light shale ceramsite filter material

Appearance: reddish brown or black grey granular

Features: 1, the proportion of small, high mechanical strength, resistance to impact wear resistance, save energy consumption and biological stability, chemical stability and thermodynamic stability is good. 2, because the surface is rough, microporous structure is rich, specific surface area, thus cutting carrying capacity is strong, hang film with high efficiency, beneficial to the growth of microorganism breeding, high biomass. 3, resistance to impact load ability, low temperature resistance, easy to hang film, start quickly, backwash low energy consumption. Purpose: acid, alkali, water filter, is the ideal water treatment products

Lightweight ceramsite filter material is a new type of biofilm carrier packing, have qualitative light, specific surface area, adsorption ability etc. Applicable to all types of filter cartridge. Compared with quartz sand, specific surface area to volume quartz sand with 2-3 times, porosity of quartz sand is 1.3 2.0 times. Compared with the sand filter, the average filter speed high (twenty - 25 m/h), water production rate, filtration cycle is long, the flushing frequency small, flushing strength low.

Shale ceramsite also called expansion shale. In clayey shale, SLATE, etc by crushing, screening, grinding or into the ball, after burn expansion a particle size in 5 ㎜ more light coarse aggregate for shale ceramsite. Shale ceramsite according to the process methods are classified into: after crushing, screening, and burn expansion and become ordinary shale ceramsite; The powder grinding, into the ball, and burn expansion a round ball shale ceramsite. Applicable from the use, the structure of heat preservation of lightweight aggregate concrete, also can be used in the structure of the use of lightweight aggregate concrete. At present shale ceramsite's main purpose is to produce lightweight aggregate concrete small hollow block and lightweight partition board. Analyze project test data analysis project test data

Specific gravity of 1.6 g/cm3 hydrochloric acid soluble rate 2.8%

Density 0.8 g/cm3 SiO2 65%

Wear rate 1.8% Al2O3 and - 22%

Porosity 56% Fe2O3 6-8%

Specific surface area > 980 cm2 / g other metal content are not overweight

Commonly used specifications: 0.5 1 mm 1-2 mm 2-3 mm 2-4 mm 3-5 mm 4 to 8 mm 5-10 mm ten to twenty mm forty - 80 mm

聯系方式:

鞏義市滿堂紅磨料磨具廠

聯系人:張娜娜

電話:18236952562

座機:0371-60329929

傳真:0371-60329622

QQ:2819618871

網址:http://mthmlmj.cn.alibaba.com/

聯系方式:

鞏義市滿堂紅磨料磨具廠

聯系人:張娜娜

電話:18236952562

座機:0371-60329929

傳真:0371-60329622

QQ:2819618871

網址:http://mthmlmj.cn.alibaba.com/

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。