| 濾料類型:陶粒 | 適用對象:水 | 用途:水過濾 |

| 性能:耐酸,耐堿,耐高溫,防火,抗凍 | 類型:高效 | 品牌:久久 |

| 吸附率:99.2(%) | 抗壓力:2850(kgf) | 密度:1.83(g/cm3) |

| 孔隙率:52(%) | 磨損率:1.6-1.8 | 硬度:6 |

| 化學成分:SiO2 Al2O3 Fe2O3 | 鹽酸可溶率:2.8(%) | 矽含量:65.4 |

| 稀土元素:1.2% | 容重:0.8 |

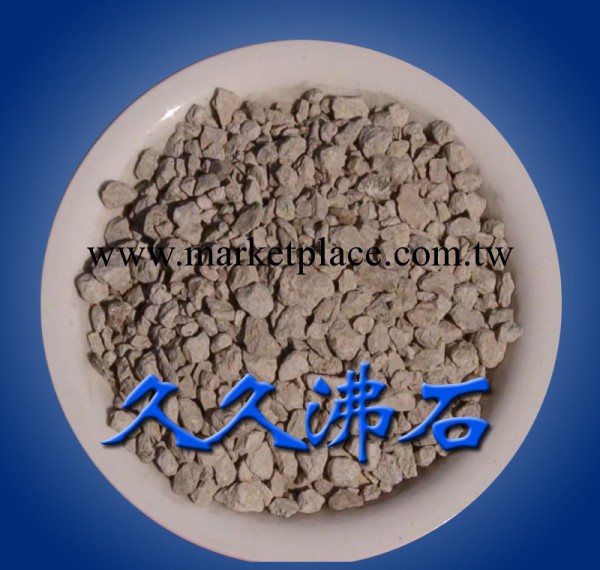

陶粒濾料采用優質陶土,粘土,粘溶劑等經團磨、篩分、煅燒加工而成,具有表麵堅硬、內部多微孔、孔隙率高等特點。以好氧活性污泥作為接種,進水兩周即可達到曝氣生物濾池的處理效果。

外觀:黑褐色球狀

成份 | SiO2 | Al2O3 | FeO3 | CaO | MgO | K2O+Na2O | 燒失量 |

含量% | 62.12 | 16.32 | 7.84 | 3.26 | 2.04 | 3.22 | 0.03% |

項 目 | 性 能 |

外觀 | 近球型,表麵深褐色,粗糙多微孔 |

規格 | Φ0.5-10mm |

視密度 | 0.80~1.20g/cm3 |

密度 | 0.95~0.98g/cm3 |

孔隙率 | ≥45~55% |

破損率 | <0.04% |

磨損率 | <3.0% |

比表麵積 | 2~6×104cm2/g |

灼燒減量 | <0.03% |

不均勻系數 | K60:1.10~1.40 |

鹽酸可溶率 | ≤0.12% |

溶出物 | 不含對人體有害的微量無素 |

吸附力 | 碘值101級為活性炭吸附力10% |

筒壓強度 | >5.0MPa |

機械強度高、耐沖刷、抗磨損、理化性能穩定,同時由於其微孔豐富、表麵粗糙、比表麵積大,使用壽命長、耐腐蝕、吸附性能好、顆粒均勻、密度適宜、不易板結、流失量小,因此截污能力強、掛膜效率高,利於微生物生長、繁殖,可有效去除水中有機物、懸浮物及氮磷等。

1.表麵多微孔(見電子顯微鏡掃描圖),比表麵積大,適合各類微生物的生長,在其表麵能形成穩定的、高活性的生物膜,處理出水水質高。

2.濾料層孔隙分佈均勻,克服瞭因濾料層孔隙分佈不均勻而引起的水頭損失大,易堵塞、板結的缺陷。

3.密度適中且均勻,反沖洗容易進行,能耗低,反沖洗中不跑料。克服瞭反沖洗難於控制和跑料的缺陷。

4.采用很好的粒徑級配,納污能力強,濾料利用率高,水頭損失增加緩慢,運行周期長,產水量大。

5.強度大、耐摩擦,物理、化學穩定性高,壽命長等。為無機惰性材料高溫燒成,長期浸泡不會向水體釋放任何物質,無二次污染。

加工制作過程中,在生產的各個環節,嚴格從粒徑、均勻度、級配、密度、粒子形狀、酸可溶率、孔隙率、比表麵積、耐摩擦等各個方麵進行把關,確保質量。目前已廣泛應用於市政污水、各種工業廢水及污水深度處理方麵。

生物陶粒濾料是一種顆粒狀水處理濾料,該濾料具有機械強度高、耐沖刷、耐磨損、理化性能穩定等特點,同時由於其微孔豐富、表麵粗糙、比表麵積大,使用壽命長、耐腐蝕、吸附性能好、顆粒均勻、密度適宜、不易結板、流失量小,因此截污能力強、掛膜效率高,又利於微生物生長、繁殖、可有效去除水中有機物,懸浮及淡磷等。

輕質陶粒濾料是一種新型的生物膜載體填料,具有質輕,比表麵積大,吸附能力強等優點。適用於各種型式的濾池濾罐。與石英砂相比,比表麵積為同體積石英砂的2-3倍,孔隙率為石英砂的1.3-2.0倍。與砂濾比較,平均濾速高(20-25m/h),產水量大,過濾周期長,沖洗頻率小,沖洗強度低。

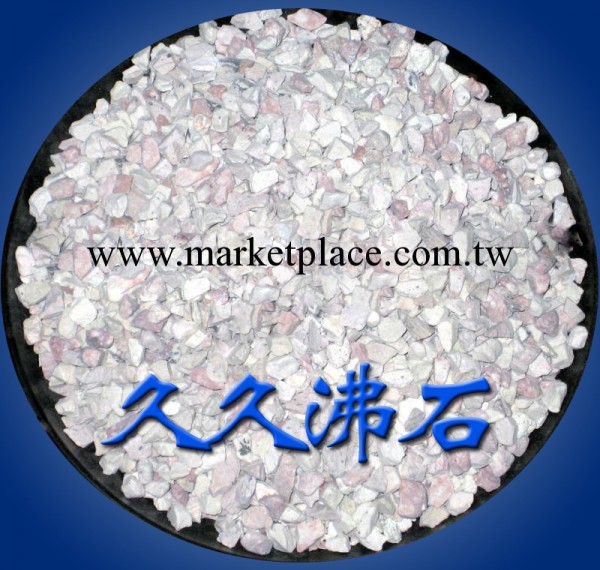

頁巖陶粒又稱膨脹頁巖。以黏土質頁巖、板巖等經破碎、篩分,或粉磨後成球,燒脹而成的粒徑在5㎜以上的輕粗集料為頁巖陶粒。頁巖陶粒按工藝方法分為:經破碎、篩分、燒脹而成的普通型頁巖陶粒;經粉磨、成球、燒脹而成的圓球形頁巖陶粒。適用於保溫用的、結構保溫用的輕集料混凝土,也可用於結構用的輕集料混凝土。目前頁巖陶粒的主要用途是生產輕集料混凝土小型空心砌塊和輕質隔墻板。

0.5-1mm 1-2mm 2-3mm 2-4mm 3-5mm 4-8mm 5-10mm 10-20mm 40-80mm

Ceramsite introduction:

Ceramsite filter material is made of high quality clay, clay, such as adhesive solvent by group grinding, screening and calcined processing and become, have it is a hard surface, internal microporous, porosity higher characteristic. In aerobic activated sludge as inoculation, water two weeks can achieve a aeration biological filter processing effect.

Appearance: dark brown ball

Ceramsite filter material chemical composition:

Ingredients SiO2 Al2O3 FeO3 CaO MgO K2O + Na2O ignition loss

Content % 62.12 16.32 7.84 3.26 2.04 3.22 0.03%

Ceramsite filter material physical index:

Item mesh sex can

Appearance nearly spherical, the surface dark brown, rough microporous

Specifications Φ 0.5 to 10 mm

Apparent density 0.80 ~ 1.20 g/cm3

Density 0.95 ~ 0.98 g/cm3

Porosity was 45 ~ 55%

Breakage rate < 0.04%

Wear rate < 3.0%

Specific surface area 2 ~ 6 x 104 cm2 / g

Ignition loss < 0.03%

Non-uniform coefficient K60:1.10 ~ 1.40

Hydrochloric acid soluble rate of 0.12% or less

Dissolve out content does not contain harmful to human body trace no meat

Adsorption force iodine value 101 level for activated carbon adsorption force 10%

Cylinder pressure strength > 5.0 MPa

Ceramsite features:

High mechanical strength, resistance to erosion, wear resistance, physical and chemical performance is stable, and at the same time, because of its microporous rich, surface roughness, specific surface area is big, long service life, resistant to corrosion, adsorption performance is good, suitable for uniform particles, density, difficult to harden, loss is small, so cut corrupt capability is strong, hang membrane efficiency is high, benefit microbial growth, reproduction, which can effectively remove organic matter in water, suspended matter and nitrogen and phosphorus, etc.

Surface microporous (see electron microscope scanning chart), specific surface area, suitable for all kinds of microbial growth, in its surface can form stable, highly active biological membrane, dealing with high water quality.

Filter material layer pore distribution uniformity, overcome the filter material layer because of the uneven distribution of pore caused by the head loss is big, easy to jam, harden defects.

Moderate density and uniform and back flush easily, low energy consumption, backwash do not run material. To overcome the backwash difficult to control and run material defect.

The good size grading, nano corrupt capability is strong, filter material utilization rate is high, the head loss increase slowly, operation cycle is long, large water production rate.

Strength, resistance to friction, physics, chemical stability, long service life, etc. For inorganic inert material high temperature firing, for a long time not to water the release of any material, no secondary pollution.

The ceramsite times:

Processing production process, in the production of each link, strictly from the size and uniformity, grading, density, particle shape, acid soluble rate, porosity, specific surface area, rubbing, and other aspects of control, to ensure quality. At present has been widely used in municipal sewage, all kinds of industrial wastewater and sewage depth treatment.

Ceramsite classification:

(1), biological ceramsite filter material

Biological ceramsite filter material is a kind of granular water treatment filter material, this filter material with high mechanical strength, resistance to erosion and wear resistance, physical and chemical stable performance, etc, and at the same time, because of its microporous rich, surface roughness, specific surface area is big, long service life, resistant to corrosion, adsorption performance is good, suitable for uniform particles, density, it is hard to form board, loss is small, so cut corrupt capability is strong, hang membrane efficiency is high, and for the microbial growth, reproduction, can effectively remove organic matter in water, suspended and light phosphorus, etc.

(2), light shale ceramsite filter material

Lightweight ceramsite filter material is a new type of biofilm carrier packing, have qualitative light, specific surface area, adsorption ability etc. Applicable to all types of filter cartridge. Compared with quartz sand, specific surface area to volume quartz sand with 2-3 times, porosity of quartz sand is 1.3 2.0 times. Compared with the sand filter, the average filter speed high (twenty - 25 m/h), water production rate, filtration cycle is long, the flushing frequency small, flushing strength low.

Shale ceramsite also called expansion shale. In clayey shale, SLATE, etc by crushing, screening, grinding or into the ball, after burn expansion a particle size in 5㎜more light coarse aggregate for shale ceramsite. Shale ceramsite according to the process methods are classified into: after crushing, screening, and burn expansion and become ordinary shale ceramsite; The powder grinding, into the ball, and burn expansion a round ball shale ceramsite. Applicable from the use, the structure of heat preservation of lightweight aggregate concrete, also can be used in the structure of the use of lightweight aggregate concrete. At present shale ceramsite's main purpose is to produce lightweight aggregate concrete small hollow block and lightweight partition board. Commonly used specifications: 0.5 1 mm 1-2 mm 2-3 mm 2-4 mm 3-5 mm 4 to 8 mm 5-10 mm ten to twenty mm forty - 80 mm

鞏義市久久拋光磨料廠

聯系人:蘇晨丹

電話:18939514537

座機:0371-60329928

傳真:0371-60329928

QQ:1985802059

網址:http://jiujiupgml.cn.alibaba.com

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。