| 加工定制:是 | 適用對象:廢舊電路板、覆銅板、線路板及邊角料等物料 | 應用領域:環保回收資源再利用 |

| 產品類型:全新 | 型號:LL-GCB800 | 品牌:LL(靈隆) |

| 產品別名:廢電路板版回收設備 | 處理能力:700-800kg/h | 用途:拆解回收金屬 |

| 作用原理:111 | 111:111 |

簡介

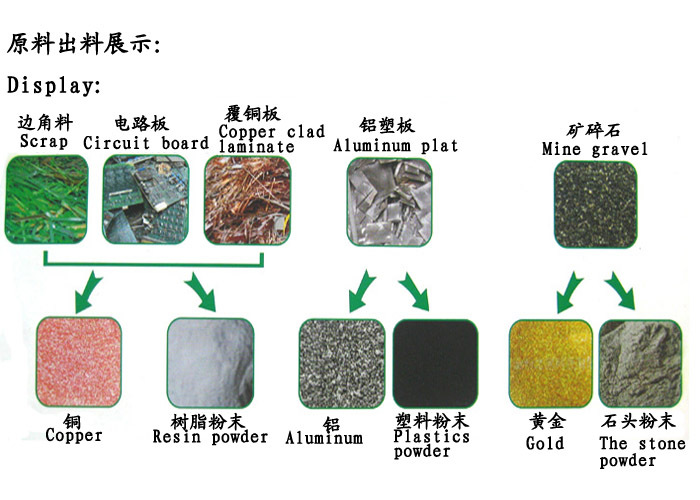

LL-GCB800廢電路板大型乾式生產線主舊電路板、覆銅板、線路板及邊角料等物料中的要用於對廢金屬與非金屬的分離。該機的開發成功不但提高瞭回收銅的質量,又防止二次污染。

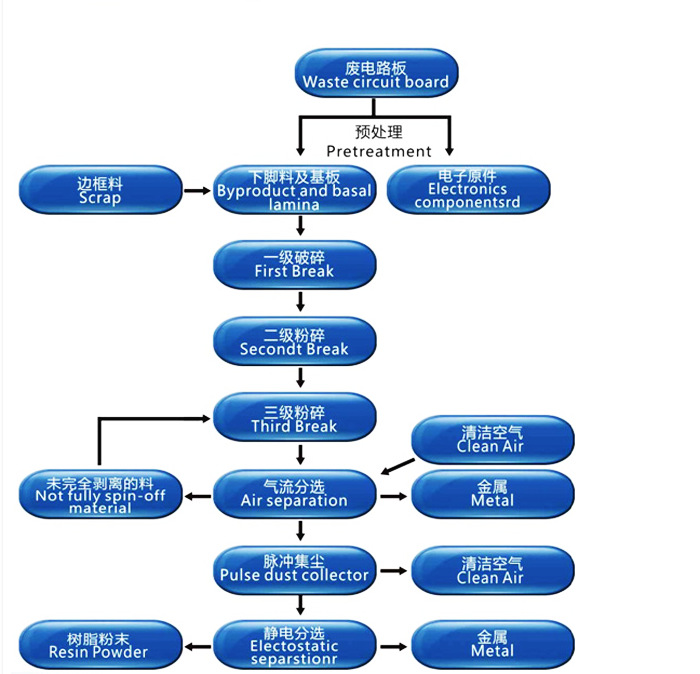

本生產線對廢電路板再生加工采取三級粉碎,使其成為金屬和樹脂纖維粉末混合物;然後通過風力和靜電分選將金屬與樹脂分離的工藝路線。為防止加工過程中的粉塵污染,在氣流分選工序後加脈沖除塵裝置,有效地解決瞭粉塵污染問題。

- 結構緊湊,佈局合理,性能穩定,噪音低。

- 采用PLC控制全套生產線均勻進料,協調運作。

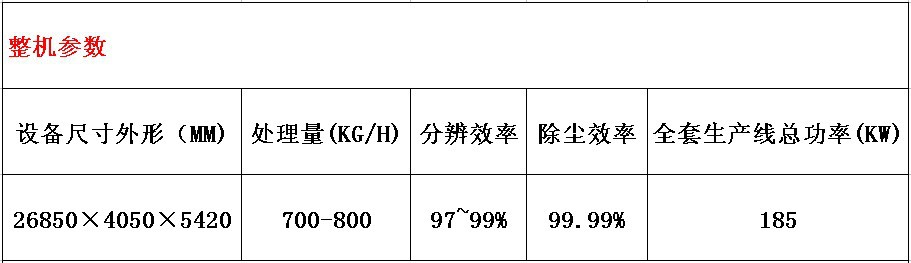

- 采用三級粉碎,使處理量達到每小時700-800kg。

- 粉碎室采用循環水控溫與降噪。

- 全套生產線采用負壓送料有效降低粉塵溢出。

- 回料系統使粉碎更高效。

- 氣流分選設備分選率高達97~99%。

- 脈沖除塵設備效率高達99.99%。

- 高壓靜電分選機使分選更精細更高效,有效控制有色金屬流失。

10.全套生產線高處置架橋與護欄,方便檢修人員對設備進行實時監控與維護。

11.廢碎設備設置液壓系統,方便更換易損件,提高工作效率。

The production line of the waste board regenerative processing take three crushed, making it a mixture of metal and resin fiber powder; then through the wind and electrostatic separation process route of the separation of metal and resin. To prevent dust pollution in the process in airflow separation process, plus pulse dust removal device, effectively solve the problem of dust pollution.

Compact structure, reasonable layout, stable performance and low noise.

2. Uniform feed full production line adopts PLC control, coordinated operation.

3 three-stage crushing, handling capacity per hour 700-800kg.

Crushing chamber with circulating water temperature control and noise reduction.

5 full production line using negative pressure feeding effectively reduce dust overflow.

Back feeding system so crushed more efficient.

7. Airflow separation equipment sorting rate of 97 to 99%.

8. Pulse dust removal equipment efficiency up to 99.99%.

9 high voltage electrostatic sorter sorting the finer more efficient, effective control of non-ferrous metal loss.

10. Complete production line of high disposal bridge and guardrail convenient access real-time monitoring and maintenance of the equipment.

11 waste and scrap the device settings hydraulic system to facilitate the replacement of wearing parts, improve work efficiency.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。