| 加工定制:是 | 品牌:臺灣仕勛 | 型號:SS200 SS250 SS350 SS500 SS700 |

| 測量范圍:0.3-110.6 | 外形尺寸:50-178(mm) | SS700-2扭力范圍:22.8-110.6 |

| SS200-1扭力范圍:0.3-1 | SS250-1扭力范圍:0.7-2.8 |

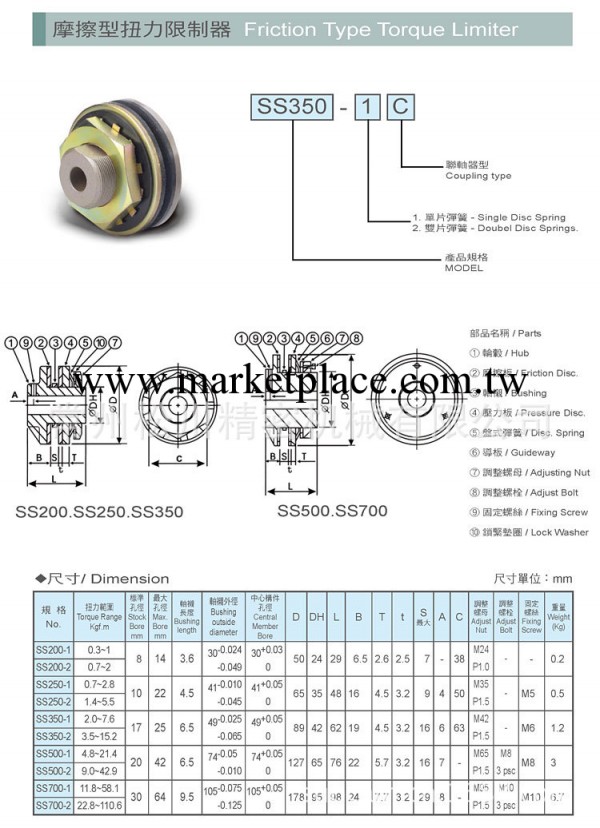

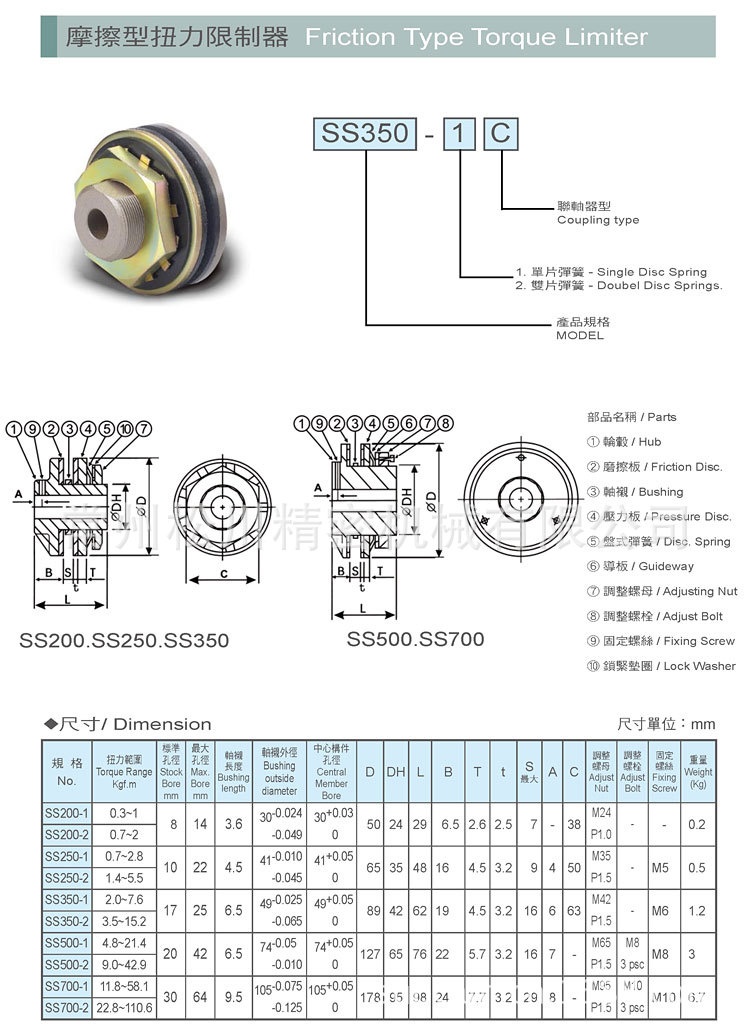

摩擦型扭力限制器Friction Type Torque Limiter

尺寸/Dimension

規格 No. | 扭力范圍 TorqueRange Kgf.m | 標準 孔徑 Stock Bore mm | 最大 孔徑 Max. Bore mm | 軸襯 長度 Bushing length | 軸襯外徑 Bushing Outside diameter | 中心構件 孔徑 Central Member Bore | D | DH | L | B | T | t | S 最大 | A | C | 調整 螺母 Adjust Nut | 調整 螺栓 Adjust Bolt | 固定 螺絲 Fixing Screw | 重量 Weight (kgf) |

SS200-1 | 0.3~1 | 8 | 14 | 3.6 | 30-0.024 -0.049 | 30+0.3 0 | 50 | 24 | 29 | 6.5 | 2.6 | 2.5 | 7 | - | 38 | M24 P1.0 | - | - | 0.2 |

SS200-2 | 0.7~2 | ||||||||||||||||||

SS250-1 | 0.7~2.8 | 10 | 22 | 4.5 | 41-0.010 -0.045 | 41+0.05 0 | 65 | 35 | 48 | 16 | 4.5 | 3.2 | 9 | 4 | 50 | M35 P1.5 | - | M5 | 0.5 |

SS250-2 | 1.4~5.5 | ||||||||||||||||||

SS350-1 | 2.0~7.6 | 17 | 25 | 6.5 | 49-0.025 -0.065 | 49+0.05 0 | 89 | 42 | 62 | 19 | 4.5 | 3.2 | 16 | 6 | 63 | M42 P1.5 | - | M6 | 1.2 |

SS350-2 | 3.5~15.2 | ||||||||||||||||||

SS500-1 | 4.8~21.4 | 20 | 42 | 6.5 | 74-0.05 -0.010 | 74+0.05 0 | 127 | 65 | 76 | 22 | 5.7 | 3.2 | 16 | 7 | - | M65 P1.5 | M8 3psc | M8 | 3 |

SS500-2 | 9.0~42.9 | ||||||||||||||||||

SS700-1 | 11.8~58.1 | 30 | 64 | 9.5 | 105-0.075 -0.125 | 105+0.05 0 | 178 | 95 | 98 | 24 | 7.7 | 3.2 | 29 | 8 | - | M95 P1.5 | M10 3psc | M10 | 6.7 |

SS700-2 | 22.8~110.6 |

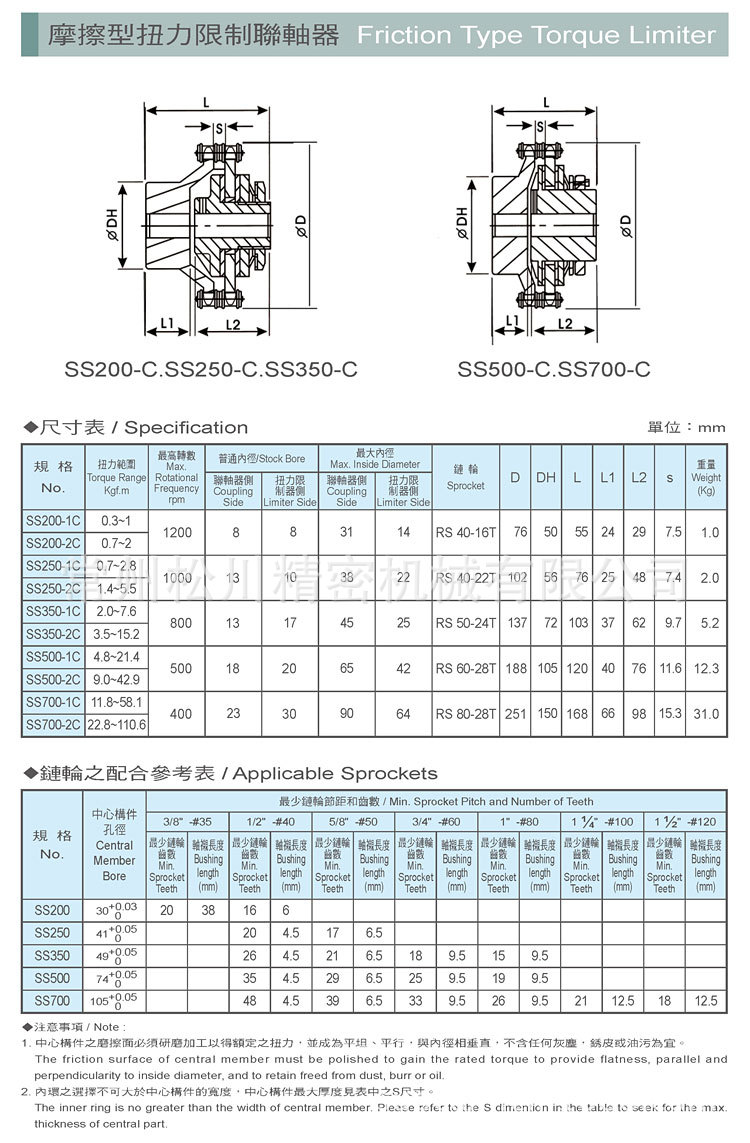

摩擦型扭力限制聯軸器Friction Type Torque Limiter

尺寸表/Specification

規格 No. | 扭力范圍 Torque Range Kgf.m | 最高轉數 Max. Rotational Frequency rpm | 普通內徑/Stock Bore | 最大內徑 Max. Inside Diameter | 鏈輪 Sprocket | D | DH | L | L1 | L2 | s | 重量 Weight (kgf) | ||

聯軸器側 Coupling Side | 扭力限 制器側 Limiter Side | 聯軸器側 Coupling Side | 扭力限 制器側 Limiter Side | |||||||||||

SS200-1C | 0.3~1 | 1200 | 8 | 8 | 31 | 14 | RS 40-16T | 76 | 50 | 55 | 24 | 29 | 7.5 | 1.0 |

SS200-2C | 0.7~2 | |||||||||||||

SS250-1C | 0.7~2.8 | 1000 | 13 | 10 | 38 | 22 | RS 40-22T | 102 | 56 | 76 | 25 | 48 | 7.4 | 2.0 |

SS250-2C | 1.4~5.5 | |||||||||||||

SS350-1C | 2.0~7.6 | 800 | 13 | 17 | 45 | 25 | RS 50-24T | 137 | 72 | 103 | 37 | 62 | 9.7 | 5.2 |

SS350-2C | 3.5~15.2 | |||||||||||||

SS500-1C SS500-2C | 4.8~21.4 9.0~42.9 | 500 | 18 | 20 | 65 | 42 | RS 60-28T | 188 | 105 | 120 | 40 | 76 | 11.6 | 12.3 |

SS700-1C | 11.8~58.1 | 400 | 23 | 30 | 90 | 64 | RS 80-28T | 251 | 150 | 168 | 66 | 98 | 15.3 | 31.0 |

SS700-2C | 22.8~110.6 | |||||||||||||

鏈輪之配合參考表/ Applicable Sprockets

規格 No. | 中心構件 孔徑 Central Member Bore | 最少鏈輪節距和齒數/Min. Sprocket Pitch and Number of Teeth | |||||||||||||

3/8” -#35 | 1/2” -#40 | 5/8” -#50 | 3/4 -#60 | 1” -#80 | 11/4” -#100 | 11/2” -#120 | |||||||||

最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | 最少鏈 輪齒數 Min Sprocket Teeth | 軸襯長度 Bushing length (mm) | ||

SS200 | 30+0.03 0 | 20 | 38 | 16 | 6 |

|

|

|

|

|

|

|

|

|

|

SS250 | 41+0.05 0 |

|

| 20 | 4.5 | 17 | 6.5 |

|

|

|

|

|

|

|

|

SS350 | 49+0.05 0 |

|

| 26 | 4.5 | 21 | 6.5 | 18 | 9.5 | 15 | 9.5 |

|

|

|

|

SS500 | 74+0.05 0 |

|

| 35 | 4.5 | 29 | 6.5 | 25 | 9.5 | 19 | 9.5 |

|

|

|

|

SS700 | 105+0.05 0 |

|

| 48 | 4.5 | 39 | 6.5 | 33 | 9.5 | 26 | 9.5 | 21 | 12.5 | 18 | 12.5 |

註意事項/Note:

- 1. 中心構件之摩擦麵必須研磨加工以得額定之扭力,並成為平坦、平行,與內徑相垂直,不含任何灰塵,銹皮或油污為宜。

The friction surface of central member must be polished to gain the rated torque to provide flatness, parallel and perpendicularity to inside diameter, and to retain freed from dust, burr or oil.

- 2. 內環之選擇不可大於中心構件的寬度,中心構件最大厚度見表中之S尺寸。

The inner ring is no greater than the width of central member. Please refer to the S dimension in the table to seek for the max. thickness of central part.

摩擦式扭力限制器

Friction Type of Torque Limiter

扭力值與鎖緊螺帽調整關系圖

Torque Value to Nut Packing Adjustment

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。

.jpg)