| 品牌:JQ | 型號:FDFB | 用途:切割 |

| 工作形式:點焊 | 驅動形式:氣動 | 電流:直流(A) |

| 作用對象:金屬 | 焊接原理:冷焊 | 動力形式:等離子 |

| 作用原理:脈沖 | 樣式:抽頭式 | 加工精度:精密 |

| 是否二手:全新 | 產品別名:拉絲機 | 電鍍位置:浸鍍 |

| 鍍種:鍍鎳系列 | 適用范圍:太陽能矽片切割 |

切割線熱處理電鍍設備規范

【歡迎咨詢: 聯系人:徐滔

手機:13962292688

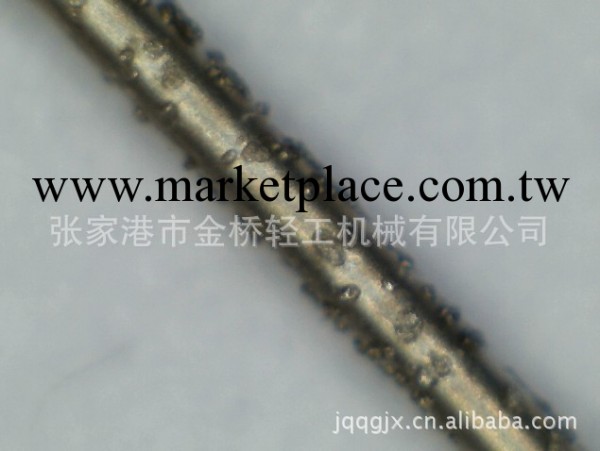

電鍍金剛砂切割線設備

1、產品型號:JQX100

1. Machine type:JQX100

2、用途:用於高碳鋼絲制造金剛石線據切割線的生產線

2. Usage: Production linehigh carbon steel wire manufacturing diamond wire cut line

3、設備尺寸:20000×1800×1600mm

3. Equipment dimension: 20000×1800×1600mm

4、生產線徑:0.10—0.40mm

4. Production diameter: 0.10-0.40mm

5、生產線速:50m/min

5.Line speed:1-20m/min

6、進線數量:單根進線

6.The number of the line: Single into the line

7、放線盤:BS200

7. Pay-off spool: BS200

8、收線盤:BS64、BS200

8. Take-up spool:BS64、BS200

9、排線方式:盤動精密排線

9.Traversing unit:Plate motion precision line

10、設備PLC控制,主傳動采用伺服電機,全機運行平穩

10.PLC control, main driving by servo motor, the machine run smoothly

11、總裝機容量約為105 KW

11. Total installed capacity is about 105 KW

12、主要部件循環泵均采用一用一備

12. Main components of circulating pump are two, one use another standby

工藝流程:

放線—堿洗—水洗—酸洗—水洗—上砂—水洗—固砂—固砂—水洗—烘乾—收線

Process:

pay-off—caustic washing—washing— pickling —washing— overlying sand—washing

—sand consolidation —sand consolidation—washing—drying —take-up

特點:本設備為本公司自主研發的電鍍金剛石切割線生產線,在國處於領先地位。整條生產線采用PLC控制方式,在線鐳射檢測線徑,圖像在線檢測觀察清晰。我公司克服瞭原來老的工藝埋砂法,落砂法,研制瞭快速電鍍物理上砂的方法,該方法具有上砂快,金剛石均勻程度比埋砂、落砂更理想,生產速度更快。

Features : This equipment is the company independent research and development, which is in the leading position in domestic.Thecompleteproduction line adopts PLC control, online laser detection diameter,image line detection observed clear.Our company overcome the old process buried sand, falling sand method,developed fast electroplating physical sand method,the method is fast on the sand, diamond uniform is more ideal than the buried sand, falling sand.

用金剛石線進行矽切片大大優於傳統切割方式,主要優點如下:

a、切割速度是砂漿切割的2倍;

b、無砂漿混合,無需建設砂漿回收系統;

c、切割表麵質量好;

d、無PEG和 SIC 的危險廢物產生;

e、清潔高效生產.

Silicon slices with diamond wire is much better than traditional cutting methods, the main advantages are as follows:

a.The cutting speed is 2 times the mortar cutting;

b. No mortar mixed mortar recovery system without construction;

c. Cutting surface good quality;

d. No PEG and SIC hazardous waste generated;

e. Clean and efficient production.

精密排線設備規范

Precise wiring equipment specification

主要技術參數:

Mechanical major specifications:

用途名稱 Application Name | 合金異型線加工,金剛石線材收線 Alloy shaped line processing, diamond wire closing line. |

進線范圍 Inlet range | 圓線:0.10 mm-0.40mm circle line:0.10 mm-0.40mm |

出線線速 Outlet speed | 0—400米 0—400M |

動力 Power | 2.2kw感應馬達變頻器控制, 2kw伺服電機一臺,收線盤為活動式裝制左右盤裝線 2.2kw induction motor inverter control, 2kw servo motor, a movable system installed around the take-up reel disk assembly line |

排線方式 Traversing unit | 臥式水平式排線,過線輪為一體式,耐磨材料 Horizontal horizontal line,Over the line wheel for one-piece, wear-resistant material |

傳動部分 Transmission parts | 伺服絲桿.聯軸器.平形帶 Servo screw, coupling, flat belts. |

卷取控制方式 Coiling control mode | 變頻張力緩沖桿,伺服恒定張力,自動演算修正控制卷取張力 Variable frequency tension buffer rod, servo constant tension, automatic calculation correction control winding tension |

機體結構 Machinestructure | 鋼板焊接而成型.經退火處理消除應力完成 Steel plate welding and forming, after annealing treatment to eliminate stress |

卷取軸盤尺寸 The take-up shaft size | BS200(可根據客戶要求)最大排線范圍360mm BS200(According to customer requirements)Biggest row line range 360mm |

上下軸方式 Bobbin loading &Unloading type | 氣動頂心螺桿緊迫式,附上下軸下線 Shaft type

|

安全罩 Safety cover | 傳動區安全罩透氣孔網狀.卷取區安全罩全密閉式附有機玻璃檢窗口 Safety cover breather hole mesh transmission area. Coiling area safety cover all closed with organic glass window |

控制 Control | 人機界麵,全數字化控制.伺服電機 Man-Machine Interface. Full digital control. Servomotor. |

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。