| 品牌:新勁成機械(K.S) | 類型:壓鑄機 | 型號:壓鑄機 |

| 主電機功率:15(kw) | 重量:5700(kg) | 外形尺寸:50001610X2320(mm) |

| 合型力:1300(kn) | 壓射力:108(kn) | 動力類型:液壓 |

| 控制形式:數控 | 適用行業:制造業各個領域 | 產品類型:全新 |

| 是否庫存:否 | 售後服務:整機保修一年 | 加工定制:是 |

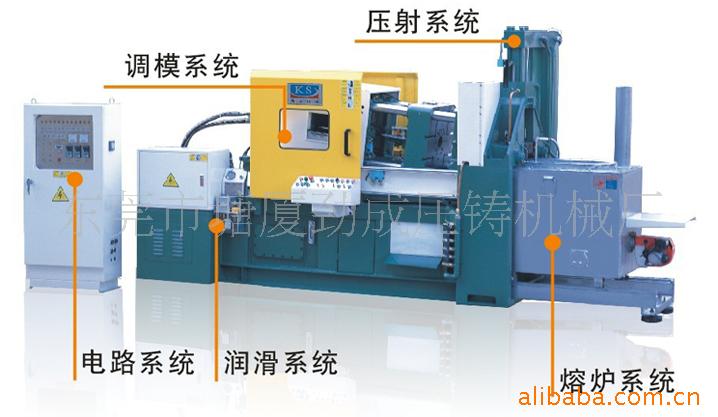

調模系統:采用全方位齒輪液壓調整,確保定動模板永久的平行。

壓射系統:采用加強棟梁式射料系統,采用大孔徑邏輯閥使之射料速度更快,適用各類產品鑄件的生產。

電路系統:擁有撥碼式和觸摸屏可選配,整機控制電路按照CE標準安全配備。

潤滑系統:采用缺油,壓力不足報警,從而更有效保護套個鎖模系統。

熔爐系統:選用設備:柴油爐、煤爐、電加熱。

項目 Projects | 單位 | KS130T |

鎖模力 Clamping force | KN | 1300 |

鎖模行程 Clamping Stroke | mm | 350 |

| 頂出力 Ejector power | KN | 88 |

| 頂出行程 Ejector Stroke | mm | 85 |

| 模具厚度(薄—厚) Mould thickness(the smaller-the largest) | mm | 170-500 |

| 模板尺寸 Moulding board size | mm | 614X636 |

| 哥林柱內距 Inner space between tiebbar | mm | 409X409 |

| 哥林柱直徑 Tiebar diameter | mm | 75 |

| 射料位置 Injection place | mm | 0-80 |

| 射料力 Injection force | KN | 108 |

| 射料行程 Injection stroke | mm | 150 |

| 離咀行程 Traverse stroke | mm | 200 |

| 錘頭直徑 Hammer diameter | mm | 60/65 |

| 射料重量 Injection weight | kg(zn) | 2.1/2.5 |

| 坩堝容積 Crucible capability | L(kg/zn) | 55(360) |

| 電機功率 Powe of motor | KW | 15 |

| 系統工作壓力 System working pressure | Mpa | 14 |

| 燃油能耗量 Eeregy consumption of Fuel | kg/h | 4.8 |

| 電爐能耗量 Eeregy consumption of Electric cooker | KW | 28 |

| 油箱容量 Oil box capability | L | 300 |

| 射咀加熱功率 Injection nozzle heating power | KW | 2.5 |

| 機械重量 Machine weight | kg | 5700 |

| 機器外形尺寸(長X寬X高)Appearance and size of machine | mm | 50001610X2320 |

1、活塞式蓄能器,配以棟梁式壓射系統。壓力損耗小,反應快,壓射速度達5M/S以上,能穩定生產薄壁壓鑄件;

2、射料油缸,儲能器經熱處理及氮氣處理永不磨損;

3、組合式壓射頭設計、配用三組德國鋼鈴,能在高溫、高速及高壓下可靠工作。

1、Piston type accumulator with a horizontal connection unit ensures lower pressure wastage and fast reaction. The injection speed can reach more than 5M/S and it can produce thin wall die castings stably.

2、Injection cylinder and accumulator are hardened by heat-treatment.

3、Combined injection plunger head design together with three groups of German piston rings can make it perform stably umder high temperature, high pressure and high speed.

1、球墨鑄鐵模板及機鉸經電腦機床加工,組成精密鎖模系統;

2、雙曲肘機鉸,運動特性符合機器開合模具要求,高速穩定;

3、特大四柱內間距及開模行程,可容納大模具及深腔模具;

4、高拉力鍍銘導柱;

5、低壓護模程序,保證模具安全。

1、S.G.lron mould platens and toggles after cutting by computer controlled machine, form precious clamping unit.

2、Moving characteristic of double tog-gle is in accordance with mould open and close requirement, which is high speed and stable.

3、Extral large space inside four tie-bars and mould open stroke can contain big moulds and deep cavity.

4、Chrome tie-bars with high tensile force.

5、Protection mould process with low pressure ensures the safety of moulds.

1、液壓控制齒輪調模裝置,操作簡單,穩定保持頭板及中板之平行度;

2、開模設有機械及油壓雙重緩沖;

3、全機各油缸、密封件都采用西德及日本高科技密封原件,耐磨、耐高溫、耐高壓及高速、壽命長。

1、Mould adjustment system is drive by hydraulic controlled gear transm-ission, which is easy for operation and can keep parallelity between head plate and middle platen.

2、Mechanical and electrical and electrical die opening are acceptable.

3、All cylinders use German oil seals to enhance the ability to withstand scrape, high temperature and pressure.

1、電熱控制射咀、鵝勁溫度;

2、射咀及鵝頭采用特有的電加熱器加熱,避免塞咀而產生次品;

3、射咀、鵝頭、壓射頭及料壺司筒采用德國優質熱作鋼制造,使用用壽命長;

4、采用瑞典名廠噴火器,操作容易,火力穩定,可靠耐用。

1、Electrically controlled temperature of nozzle and goose neck.

2、Nozzle and goes neck are heated by electric heater to avoid jamming of nozzle resulting defective products.

3、Nozzle, gooes neck, injection plunger head and melting pot sleeve are made from hot work steel from Germany, so their life spans are long.

4、Oil injection burner from famous Swedish maker is adopted. It's easy to operate and it is reliable and durable with stable firepower.

標準配備自動潤滑裝置

1、定量卸壓式集中稀油潤滑裝置,由主機PLC控制,能實現自動供送油濟,監控潤滑系統失壓及低油位發訊;

2、潤滑油廢油被集中收集到一個地方排出。

1、Its quantificational pressure releasing centralized oil thinning lubricating deveice is controlled by PLC of main machine, It can realize oil supply and monitor lubricating system and send signal when pressure is lost and oil leve is low.

2、It is designed to collect the waste lubricating oil in one spot for discharge.

1、日本名廠電腦程序控制器,操作簡單,工作穩定。控制和監視整機工作狀況,能迅速排除故障;

2、觸屏式人機界麵,無須按鍵,輕松實現各種參數的設定和調校;

3、采用近接開關及行程開關控制,信號準確可靠;

4、機器強弱電分隔佈置,增強安全性和可靠性。

1、Programmable logic controller is from famous Japanese maker with easy operation and stable performance. It controls and monitors working status of the machine and can clear trouble immediately.

2、Screen touch human-computer interface. No need to press buttons for srtting and adjustment of parameters.

3、Proximity switch and limit switch are adopted to obtain accurate and reliable signals.

4、Different compartments for strong and light current are arranged to enhance safety and reliability.

1、油泵油閥:采用原裝進口液壓元件〈油研、力士樂、威格士等品牌〉。

2、電腦(PLC)電器元件:采用日本三菱電腦,具有故障顯示報警功能.電器元件采用日本或歐美產品。

3、電機:采用東莞環球電機(全國免檢產品)。

4、哥林柱:采用優質高抗拉力材料,內部采用調質去應力處理,外部采用表麵滲碳精磨鍍硬鉻工藝,比其它同類型產品壽命更長。

5、油管:采用臺灣知名產品,內含四層鋼絲,更加經久耐用。

6、模板:采用國內目前可延伸系數高達700的高韌性球鐵。具有耐用,不變形等特點。

7、調模機構:油壓式齒輪調模,操作簡單、穩定性高。

8、射料機構:加強型兩速射料控制;經改進後的射料系統,其穩定性更強.適合一切高品質鑄件的生產,而且熱作件通用性廣,大大節省客戶使用成本。

9、安全保護:機器自動潤滑時,欠壓缺油自動停機。另具有鎖模低壓保護、手動鎖模雙手操作、鎖模機後無人操作及射料動作六級防護等保護程序,有效保護機器、模具及操作工的安全。

全天候提供壓鑄機售後服務.並承諾在接到客戶電話後安排服務人員按時到達。

1、整機保用壹年,大件(模板,哥林柱)保用兩年。

2、保質期過後,所有零配件原則上隻收取成本費用。

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。