產品的特性為;

1.電壓為 1.45-1.5-1.55V

2.電流為 10MIL 30豪安 12MIL 50毫安 14MIL 80毫安 16MIL 100毫安 40MIL 300毫安 42MIL的用 1000毫安

3.角度為 15° 30° 45° 60°80°120°

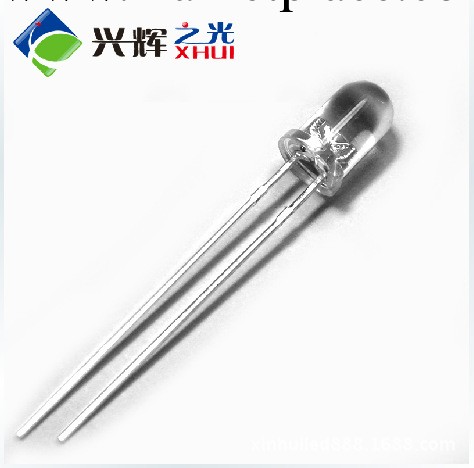

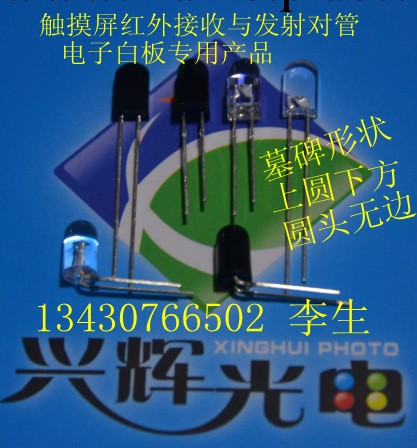

4.外形尺寸5MM*8.6MM 圓頭 有邊和無邊

5.引腳 短角為 15-18MM 長角為25-28MM 正負角相隔1.5MM

?High reliability

?High radiant intensity

?Peak wavelength λp=850nm

?2.54mm Lead spacing

?Low forward voltage

?The product itself will remain within RoHS compliant version.

?Xinghui’s Infrared Emitting Diode is a high intensity diode , molded in a water clear plastic package.

?The device is spectrally matched with phototransistor , photodiode and infrared receiver module.

?Free air transmission system

?Opto electronic switch

?Infrared applied system

?Smoke detector

LED Part No. | Chip Material | Lens Color |

IRP3014C10 | GaAlAs | Water clear |

Continuous Forward Current | IF | 30 | mA |

Peak Forward Current | IFP | 1 | A |

Reverse Voltage | VR | 5 | V |

Operating Temperature | Topr | -40 ~ +85 | ℃ |

Storage Temperature | Tstg | -40 ~ +85 | ℃ |

Soldering Temperature | Tsol | 260 | ℃ |

Power Dissipation at25℃Free Air Temperature | Pd | 50 | mW |

*2:Soldering time≦5 seconds.

Radiant Intensity | IE | IF=20mA | 7.8 | 15 | -- | mW/sr |

Radiant Intensity | IE | IF=100mA Pulse Width≦100μs ,Duty≦1% | -- | 100 | -- | mW/sr |

Radiant Intensity | IE | IF=1A Pulse Width≦100μs ,Duty≦1% | -- | 950 | -- | mW/sr |

Peak Wavelength | λp | IF=20mA | -- | 850 | -- | nm |

Spectrial Bandwidth | Δλ | IF=20mA | -- | 45 | -- | nm |

Forward | VF | IF=20mA |

| 1.45 | 1.65 | V |

Forward | VF | IF=100mA Pulse Width≦100μs ,Duty≦1% | -- | 1.8 | 2.40 | V |

Forward Voltage | VF | IF=1A Pulse Width≦100μs ,Duty≦1% | -- | 4.1 | 5.25 | V |

Reverse Current | IR | VR=5V | -- | -- | 5 | μA |

View Angle | 2θ1/2 | IF=20mA | -- | 25 | -- | deg |

1. Lead Forming a) During lead formation, the leads should be bent at a point at least 3mm from the base of the epoxy bulb. b) Lead forming should be done before soldering. c) Avoid stressing the LED package during leads forming. The stress to the base may damage the LED’s characteristics or it may break the LEDs. d) Cut the LED leadframes at room temperature. Cutting the leadframes at high temperatures may cause failure of the LEDs. e) When mounting the LEDs onto a PCB, the PCB holes must be aligned exactly with the lead position of the LED. If the LEDs are mounted with stress at the leads, it causes deterioration of the epoxy resin and this will degrade the LEDs. 2. Storage a) The LEDs should be stored at 30°C or less and 70%RH or less after being shipped fromXinghuiand the storage life limits are 3 months. If the LEDs are stored for 3 months or more, they can be stored for a year in a sealed container with a nitrogen atmosphere and moisture absorbent material. b) Please avoid rapid transitions in ambient temperature, especially, in high humidity environments where condensation can occur. 3. Soldering a) Careful attention should be paid during soldering. When soldering, leave more then 3mm from solder joint to epoxy bulb, and soldering beyond the base of the tie bar is recommended. b) Recommended soldering conditions: Hand Soldering DIP Soldering Temp. at tip of iron 300℃Max. (60W Max.) Preheat temp. 100℃Max. (60 sec Max.) Soldering time 3 sec Max. Bathtemp. & time 260 Max., 5 sec Max Distance 3mmMin.(From solder joint to epoxy bulb) Distance 3mmMin. (From solder joint to epoxy bulb) 1. Above specification may be changed without notice, XingHui will reserve authority on material change for above specification. 2. When using this product, please observe the absolute maximum ratings and the instructions for using outlined in these specification sheets. XingHui assumes no responsibility for any damage resulting from use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets. 3. These specification sheets include materials protected under copyright of XingHui company. Please don’t reproduce or cause anyone to reproduce them without XingHui’s consent.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。