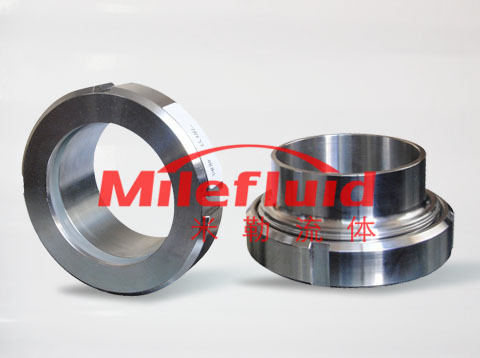

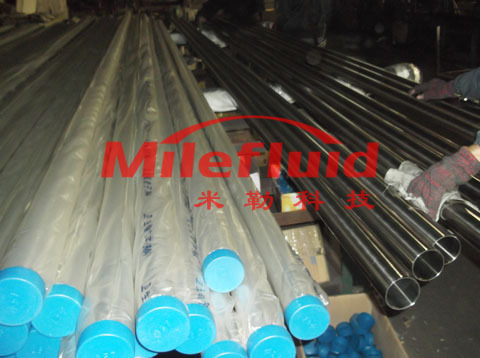

產品名稱:304或316L不銹鋼管,衛生級鋼管,不銹鋼鋼管(生產廠傢,規格);

衛生級不銹鋼管是一種具有中空截面、周邊沒有接縫的長條鋼材。該產品的壁厚越厚,它就越具有經濟性和實用性,壁厚越薄,它的加工成本就會大幅度的上升;該產品的工藝決定它的局限性能,一般無縫鋼管精度低:壁厚不均勻、管內外表光亮度低、定尺成本高,且內外表還有麻點、黑點不易去除;它的檢測及整形必須離線處理。304或316L不銹鋼管,衛生級鋼管,不銹鋼鋼管(生產廠傢,規格);因此它在高壓、高強度、機械結構用材方面體現瞭它的優越性。

其一、該產品的壁厚越厚,它就越具有經濟性和實用性,壁厚越薄,它的加工成本就會大幅度的上升;其二、該產品的工藝決定它的局限性能,一般無縫鋼管精度低:壁厚不均勻、管內外表光亮度低、定尺成本高,且內外表還有麻點、黑點不易去除;其三、它的檢測及整形必須離線處理。因此它在高壓、高強度、機械結構用材方面體現瞭它的優越性。 不銹鋼無縫管的種類: 按軋制方法分熱軋、熱擠壓和冷拔(軋)不銹鋼管。 按不銹鋼金相組織不同分半鐵素體半馬氏體系不銹鋼無縫管、馬氏體不銹鋼無縫管、奧氏體系不銹鋼無縫管、奧氏體-鐵素鐵系不銹鋼無縫管等。

不銹鋼管規格及外觀質量:

A、按GB14975-2002《不銹鋼無縫鋼管》規定,鋼管通常長度(不定尺)熱軋鋼管1.5~10m,熱擠壓鋼管等於和大於1m。冷拔(軋)鋼管壁厚0.5~1.0mm者,1.0~7m;壁厚大於1.0mm者,1.5~8m。

B、熱軋(熱擠壓)鋼管的直徑54~480mm共45種;壁厚4.5~45mm共36種。冷拔(軋)鋼管的直徑6~200mm共65種;壁厚0.5~21mm共39種。

C、鋼管內外表面不得有裂縫、折疊、龜裂、裂紋、軋折、離層和結疤缺陷存在,這些缺陷應完全清除掉(供機械加工用管除外),清除後不得使壁厚和外徑超過負偏差。304或316L不銹鋼管,衛生級鋼管,不銹鋼鋼管(生產廠傢,規格);凡不超過允許負偏差的其他輕微表面缺陷可不清除。

D、直道允許深度。熱軋、熱擠壓鋼管、直徑小於和等於140mm的不大於公稱壁厚的5%,最大深度不大於0.5mm;冷拔(軋)鋼管不大於公稱壁厚的4%,最大深度不大於0.3mm。

E、鋼管兩端應切成直角,並清除毛刺。不銹鋼無縫管的制造工藝:

1.熱軋(擠壓無縫鋼管):圓管坯→加熱→穿孔→三輥斜軋、連軋或擠壓→脫管→定徑(或減徑)→冷卻→矯直→水壓試驗(或探傷)→標記→入庫 軋制無縫管的原料是圓管坯,圓管胚要經過切割機的切割加工成長度約為1米的坯料,並經傳送帶送到熔爐內加熱。鋼坯被送入熔爐內加熱,溫度大約為1200攝氏度。燃料為氫氣或乙炔。爐內溫度控制是關鍵性的問題.圓管坯出爐後要經過壓力穿孔機進行穿空。一般較常見的穿孔機是錐形輥穿孔機,這種穿孔機生產效率高,產品質量好,穿孔擴徑量大,可穿多種鋼種。穿孔後,圓管坯就先後被三輥斜軋、連軋或擠壓。擠壓後要脫管定徑。定徑機通過錐形鑽頭高速旋轉入鋼胚打孔,形成鋼管。鋼管內徑由定徑機鑽頭的外徑長度來確定。鋼管經定徑後,進入冷卻塔中,通過噴水冷卻,鋼管經冷卻後,就要被矯直。鋼管經矯直後由傳送帶送至金屬探傷機(或水壓實驗)進行內部探傷。若鋼管內部有裂紋,氣泡等問題,將被探測出。鋼管質檢後還要通過嚴格的手工挑選。鋼管質檢後,用油漆噴上編號、規格、生產批號等。並由吊車吊入倉庫中。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。。

2.冷拔(軋)無縫鋼管:圓管坯→加熱→穿孔→打頭→退火→酸洗→塗油(鍍銅)→多道次冷拔(冷軋)→坯管→熱處理→矯直→水壓試驗(探傷)→標記→入庫。 冷拔(軋)無縫鋼管的軋制方法較熱軋(擠壓無縫鋼管)復雜。它們的生產工藝流程前三步基本相同。不同之處從第四個步驟開始,圓管坯經打空後,要打頭,退火。退火後要用專門的酸性液體進行酸洗。酸洗後,塗油。然後緊接著是經過多道次冷拔(冷軋)再坯管,專門的熱處理。熱處理後,就要被矯直。鋼管經矯直後由傳送帶送至金屬探傷機(或水壓實驗)進行內部探傷。若鋼管內部有裂紋,氣泡等問題,將被探測出。鋼管質檢後還要通過嚴格的手工挑選。鋼管質檢後,用油漆噴上編號、規格、生產批號等。並由吊車吊入倉庫中。

化學成分檢驗

1、按化學成分和機械性能供應的國產無縫管,如10、15、20、25、30、35、40、45和50號鋼的化學成分應符合GB/T699-88的規定。進口無縫管按合同規定的有關標準檢驗。09MnV、16Mn、15MnV鋼的化學成分應符合GB1591-79的規定。

2、具體分析方法參照GB223-84《鋼鐵及合金化學分析方法》的有關部分。

3、分析偏差參照GB222-84《鋼的化學分析用試樣及成品化學成分允許偏差》。

化學成分檢驗

1、按化學成分和機械性能供應的國產無縫管,如10、15、20、25、30、35、40、45和50號鋼的化學成分應符合GB/T699-88的規定。進口無縫管按合同規定的有關標準檢驗。09MnV、16Mn、15MnV鋼的化學成分應符合GB1591-79的規定。

2、具體分析方法參照GB223-84《鋼鐵及合金化學分析方法》的有關部分。

3、分析偏差參照GB222-84《鋼的化學分析用試樣及成品化學成分允許偏差》。

化學成分檢驗

1、按化學成分和機械性能供應的國產無縫管,如10、15、20、25、30、35、40、45和50號鋼的化學成分應符合GB/T699-88的規定。進口無縫管按合同規定的有關標準檢驗。09MnV、16Mn、15MnV鋼的化學成分應符合GB1591-79的規定。

2、具體分析方法參照GB223-84《鋼鐵及合金化學分析方法》的有關部分。304或316L不銹鋼管,衛生級鋼管,不銹鋼鋼管,不銹鋼無縫管;

3、分析偏差參照GB222-84《鋼的化學分析用試樣及成品化學成分允許偏差》。

溫州米勒流體設備科技有限公司專業供應優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304或316L不銹鋼管,衛生級鋼管,不銹鋼鋼管,不銹鋼無縫管;304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。優質衛生級鋼管,不銹鋼無縫鋼管,不銹鋼焊管,304不銹鋼無縫管或316L不銹鋼焊管。

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - -- - -- --

Stainless steel seamless pipe is a hollow cross section, peripheral joints of the long strips of steel.The thicker the wall thickness of the product, it is more economical and practical wall thickness of the thinner, its processing costs will be substantially increased; the product process to determine its limitations can generally seamless steel tube precision: uneven thickness, the appearance of low brightness tube, the high cost of fixed length, and within the appearance of pitting and black spots difficult to remove; detection and plastic must be processed offline.So it is at high pressure, high strength, the mechanical structure timber reflects its superiority.

First, the thicker the wall thickness of the product, it is more economical and practical wall thickness of the thinner, its processing costs will be substantially increased; Second, the process of the product to determine its limitations.The low accuracy of the general seamless steel pipe: non-uniform wall thickness, the appearance of low brightness tube length high cost, and within the appearance of pitting and black spots difficult to remove; Third, the detection and plastic must be processed offline.So it is at high pressure, high strength, the mechanical structure timber reflects its superiority.Types of stainless steel seamless pipe: points by rolling method, hot-rolled, hot extruded and cold drawn (rolled) stainless steel tube.Different points of semi-ferritic martensitic stainless steel seamless pipe stainless steel microstructure, martensitic stainless steel seamless pipe, austenitic stainless steel seamless pipe, austenitic - ferritic iron, stainless steel seamless pipe.

Stainless steel pipe specifications and appearance quality:

A, according to the provisions of the GB14975-2002 stainless steel seamless pipe, steel pipe is usually (not length) in length 1.5 ~ 10m of hot-rolled steel, hot extruded steel pipe is equal to and greater than 1m.Cold drawn (rolled) steel pipe wall thickness 0.5 ~ 1.0mm, 1.0 ~ 7m; wall thickness greater than 1.0mm, 1.5 ~ 8m.B, hot-rolled (hot extrusion) and the diameter 54 ~ 480mm 45 kinds; wall thickness of 4.5 ~ 45mm, a total of 36 kinds.Cold drawn (rolled) and the diameter of 65 kinds of 6 ~ 200mm; wall thickness of 0.5 ~ 21mm 39.Steel inner and outer surfaces shall not have cracks, folding, cracking, cracks, rolling, folding, ionosphere and scarring and defects, these defects should be completely removed (for machining pipe excluded), shall not be cleared so that the wall thickness and outsidediameter of more than a negative deviation.That do not exceed the allowable negative deviation and other minor surface defects from time to clear.D, straight allows depth.Hot-rolled, hot extruded steel pipe, the diameter is less than or equal to 140mm, is not greater than the nominal wall thickness of 5%, the maximum depth of not more than 0.5mm; cold drawn (rolled) steel is not greater than 4% of the nominal wall thickness, the maximumThe depth is not greater than 0.3mm.Steel pipe at both ends cut at right angles and and clear the glitch.Stainless steel seamless pipe manufacturing process: (1) hot-rolled (extrusion seamless steel tubes): round tube → heating → perforation → three-roll cross rolling, rolling or extrusion → detached → sizing (or reducing) →cooling → straightening → hydrostatic test (or testing) → marker → raw materials storage rolling seamless pipe is round tube, the tube embryos to go through a cutting machine cutting processing growth of about 1 meter blank, and byconveyor sent to the furnace heating.Billet is fed into the heating furnace, the temperature is about 1200 degrees Celsius.Fuel for a hydrogen or acetylene.The furnace temperature control is critical to wear air tube round, after the release of pressure puncher.Are generally more common puncher tapered roller punch this punch, high production efficiency, product quality, perforated expanding volume, wearing a variety of steels.After perforation, round tube has been three-roll cross rolling, rolling or extrusion.After extrusion off pipe sizing.Sizing mill by the high-speed rotation of the cone drill into the Billet punch to form a steel pipe.The steel pipe inner diameter is determined by the length of the outer diameter of the sizing mill drill.After sizing, the steel pipe to enter the cooling tower by the water spray cooling, the steel pipe after cooling, it is necessary to be straightening.Sent by conveyor pipe by straightening the metal detection machine (or hydrostatic test) to conduct an internal flaw.Steel pipe internal issues such as cracks, bubbles will be detected.Steel pipe quality inspection but also through a rigorous manual selection.Steel pipe of Quality Supervision, Inspection, use spray paint on the number, size, production batch.By a cable car hanging into the warehouse.(2) cold drawn (rolled) seamless steel tubes: tube round → heating → perforation → Heading → annealing → pickling → Oiler (copper) → multi-pass cold drawn (cold) → Preform → heat treatment → straightening→ hydrostatic test (testing) → marker → storage.Cold drawn (rolled) seamless steel pipe rolling method than hot-rolled (extrusion of seamless steel pipe) complex.The first three steps of their production process is basically the same.The difference from the fourth step, the circular tube was empty to begin annealing.After annealing, pickling to use a special acidic liquid.After pickling and oiling.Then followed by a blank tube, multi-pass cold drawn (cold) and then specialized heat treatment.After heat treatment, it is necessary to straightening.Sent by conveyor pipe by straightening the metal detection machine (or hydrostatic test) to conduct an internal flaw.Steel pipe internal issues such as cracks, bubbles will be detected.Steel pipe quality inspection but also through a rigorous manual selection.Steel pipe of Quality Supervision, Inspection, use spray paint on the number, size, production batch.By a cable car hanging into the warehouse.

A manufacturing method

Production methods can be divided into hot-rolled tubes, cold-rolled pipes, cold drawn tube, squeeze tubes.1.1, hot-rolled seamless pipe is generally automatic pipe mill production.Solid tube and clear upon inspection of surface defects, the cut into the desired length in the tube perforated end to end surface of the centering, and then sent to the furnace heating puncher perforation.Perforation at the same time continue to rotate and advance the role of the roll and head tube internal cavity, said capillary.And then sent to the automatic rolling machine to continue rolling.And finally by all the whole entire wall thickness, sizing mill sizing, to achieve the specifications.Continuous pipe mill producing hot-rolled seamless steel pipe is a more advanced method.1.2 putting up a smaller size and better quality seamless tubes, cold-rolled, cold drawn or both methods.Cold rolled usually in two-roll mill, steel rolling in the ring pass a variable cross-section hole slot and fixed cone head.Cold drawing is usually in the 0.5 ~ 100T single chain or double chain drawing machine.1.3, extrusion is about to heat a good tube placed in closed extrusion cylinder, perforated rods and extruded rod with movement, so that the extrusion extrusion from the die hole of smaller.This method can produce smaller diameter steel pipe.

2, the chemical composition of test

2.1, according to chemical composition and mechanical properties of the supply of domestic seamless pipe, such as the chemical composition of steel 10,15,20,25,30,35,40,45 and 50 should meet the provisions of the GB/T699-88.Imports of seamless pipe inspection by the relevant standards of the contract.09MnV, 16Mn, 15MnV steel chemical composition shall comply with the provisions of GB1591-79.2.2, the specific analytical methods with reference to the relevant part of the GB223-84 steel and alloy chemical analysis method.Deviation of 2.3, analysis reference to GB222-84 steel, chemical analysis of the sample and refined chemical composition tolerances ".

3, physical performance test

3.1, according to the institutional performance of the supply of domestic seamless pipe, ordinary carbon steel GB/T700-88 A steel manufacturing (but must ensure that the sulfur content of no more than 0.050 percent and phosphorus content of not more than 0.045%), its mechanicalperformance should be consistent with the values ??specified in GB8162-87 table.3.2 must ensure that the standards required by the hydrostatic test hydrostatic test the supply of domestic seamless pipe.3.3, imports of seamless tube, physical performance test according to the standards stipulated in the contract.2, uses 2.1, seamless pipe use is extensive.The general purpose of seamless pipe from ordinary carbon steel, low alloy steel or alloy structural steel rolling, most productive, mainly used as a pipe or structural parts of the transmission fluid.2.2, according to the supply of different purposes into three categories: a supply of chemical composition and mechanical properties; b, the supply of mechanical properties; supply of hydraulic pressure test.A, b supply steel pipe, such as to withstand the fluid pressure, but also the hydrostatic test.2.3, the special purpose of seamless boiler seamless pipe, seamless tube and petroleum geology seamless tube variety.3, type 3.1, seamless steel pipe production methods can be divided into hot-rolled tubes, cold-rolled pipes, cold drawn tube, squeeze tubes.3.2, according to the circular pipe, shaped tube shape classification.Shaped tube addition to the square tube and rectangular tube, oval tube, semicircle tube, triangle tube, hexagon tube, convex-shaped tube, plum-shaped tube.3.3, according to the different materials, divided into ordinary carbon structural tube, low-alloy structural pipe, high-quality carbon structural tube, alloy pipe, stainless steel tube.3.4, according to the points of special purpose, boiler tubes, geological tubes, oil tubes.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。