供應95 96 98優質增碳劑

增碳劑簡介:

增碳劑的原料有很多種,生產工藝也各異,有木質碳類,煤質碳類,焦炭類,石墨類等,其中各種分類下又有很多小種類。優質增碳劑一般指經過石墨化的增碳劑,在高溫條件下,碳原子的排列呈石墨的微觀形態,所以稱之為石墨化。石墨化可以降低增碳劑中雜質的含量,提高增碳劑的碳含量,降低硫含量。適用於鑄鋼(煉鋼)以及灰鐵鑄造增碳。具有高碳、低硫、低含水量且成本低及性價比高的特點。

增碳劑指標:

規格 | 固定碳% | 硫% | 氮% | 水份% | 灰份% | 揮發份% |

3-6mm | 98 | 0.02 | 0.01 | 0.5 | 0.5 | 0.5 |

3-6mm | 96 | 0.03 | 0.01 | 0.8 | 1 | 0.7 |

1-5mm | 95 | 0.05 | 0.01 | 1.0 | 2 | 1 |

1-5mm | 92 | 0.05 | 0.01 | 1.0 | 3 | 2 |

增碳劑用途:

適用熔煉工藝:

感應電爐爐內增碳;沖天爐爐內增碳;雙聯工藝增碳;爐前鐵水包隨流增碳。

強烈推薦球鐵廠傢使用本廠低硫低氮石墨增碳劑。

石墨化增碳劑產品使用方法:在電爐底部放置爐料三分之一後將計算好的產品放置在爐料上,(爐中放一部分料後放增碳劑)然後把剩餘爐料按要求放在上麵,如上麵的爐料較大時應把一些較碎的爐料壓在增碳劑上,以防止漂浮影響吸收率。增碳劑加入量是金屬量的1-3%,用戶也可根據產品生產質量要求自行調整。增碳劑的特點是碳在鐵液中吸收效果好,不返渣,使用增碳劑可大幅度降低鑄件生產成本。

增碳劑特點:

1、高固定碳,吸收率高,低硫低氮,並在吸收速度上快於同類石墨化增碳劑,且不吸附爐壁,完全吸收無殘留,價格低於同類硫低於0.05以下的石墨化增碳劑,性價比最高。

2吸收率高, 根據使用方法吸收率最高能達到90%以上.

3吸收速度快,比同類石墨化增碳劑吸收速度快,不吸附爐壁,且無殘留,爐中增碳吸收速度優勢更加明顯.

4硫份低, 0.05%以下,最低0.02%。氮份低,100ppm以下

5超高的性價比,綜述上述在同類石墨化增碳劑中(硫≤0.05)價格最有優勢。

增碳劑使用方法:

①.5噸以上電爐,推薦分散加入法。根據含碳量要求按配料比將增碳劑與金屬爐料隨其它配料一同加入電爐中下部位。

②.使用2-3噸左右中頻感應電爐,推薦集中加入法:在爐內先熔化部分鐵水或剩餘少量鐵水時,將需要配加的增碳劑一次性加在鐵水表麵,並立即添加金屬爐料,將增碳劑全部壓入鐵水中,使增碳劑與鐵水充分接觸。

③.使用小型中頻電爐,如原料單一穩定,推薦將增碳劑集中加在爐子下部;原料夾有生鐵等高碳物質的,則推薦增碳劑微調:即鋼或鐵水熔化後調整含碳,可以加在鋼或鐵水表麵,通過熔煉時鐵水的渦流攪拌使本產品溶解吸收。

優質增碳劑具備的特性

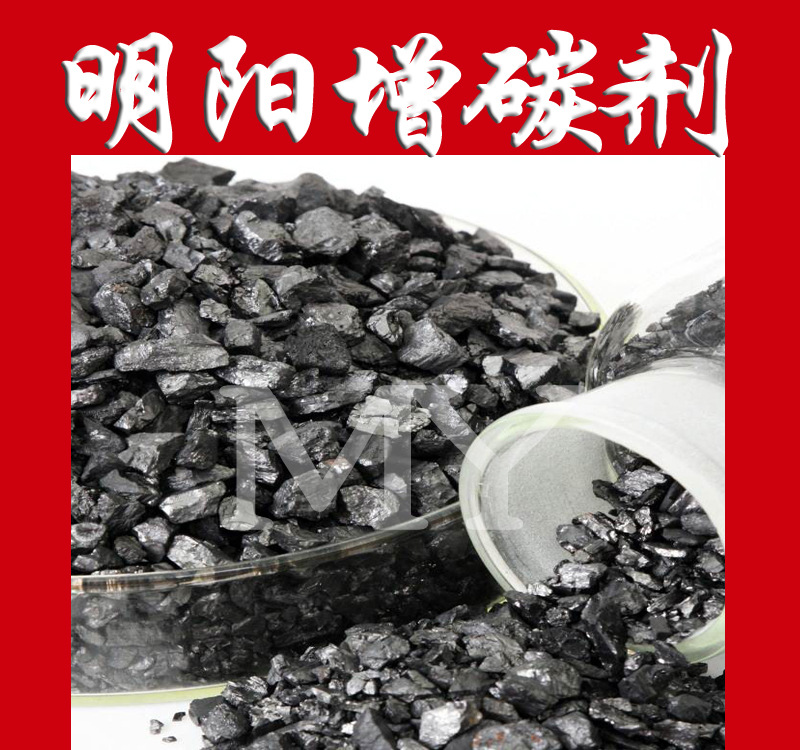

1.顆粒大小適中,孔隙度大,吸收速度快。

2.化學成分純凈,高碳、低硫、有害成分極微,吸收率高。

3.產品石墨晶體結構好,提高原鐵液的形核能力。在孕育中增加球墨鑄鐵的 墨球數量,在電爐鐵液中增加石墨晶核。細化、均勻化石墨在鑄件中的分佈。

4.性能優異、穩定。選用合適的增碳劑有助於降低冶煉生產成本,提高冶煉金屬及鑄件的質量。

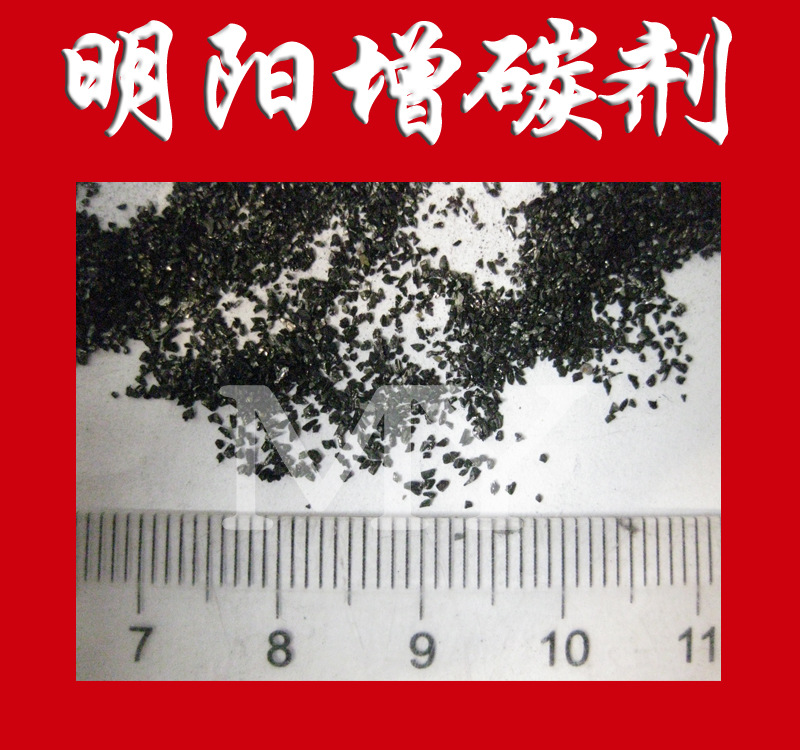

增碳劑規格:

0.5-1 1-2 2-4 4-6 6-8 8-10 1-3 3-5 5-8mm等多種規格,可按客戶要求調整生產。

增碳劑包裝方式:

25kg/袋,雙層編織代包裝,也可使用噸袋包裝,具體包裝要求可按客戶要求調整生產。

Recarburizerprofile:

Carburant, there are many kinds of raw materials, production process is different, the woodiness carbon, coal carbon, coke, graphite type, etc., and there are many small categories under which various classification. High quality recarburizer generally refers to after graphitization of carburant, under the condition of high temperature, the microstructure of carbon atoms arranged in graphite, so called the graphitization. Graphitization can reduce the impurity content of a carburant, viscosity increasing carbon content, carbon agent to reduce sulfur content. Apply to cast iron (steel) and grey iron casting carburization. Have high carbon, low sulfur, low water content and the characteristics of low cost and high cost performance.

Recarburizer indicators:

Specification of fixed carbon sulfur % n % % % % ash % moisture volatilize

3-6 mm 98 0.02 0.01 0.5 0.5 0.01

3-6 96 0.03 0.01 0.8 0.7 1 mm

1-5 mm 95 0.05 0.01 1.0 2 1

92 0.05 0.01 1.0 3 2 1-5 mm

Recarburizer purposes:

Melting process shall apply:

Induction furnace furnace carbonization; Cupola furnace carbonization; Duplex process increase carbon; Before the furnace hot metal ladle carbon over flow.

Ductile iron manufacturers are strongly recommended to use this factory low sulfur, low nitrogen graphite recarburizer.

Graphitization recarburizer product usage: in the electric furnace is placed at the bottom of the furnace charge will be calculated after a third good product placed on the furnace charge, (after the furnace put part of the material put recarburizer) and then put the remaining charge according to the requirements above, such as when the burden is bigger, should put some more crushing burden of pressure on the carburant, to prevent the floating effect absorption rate. Recarburizer addition amount is 1-3% of metal, user can also adjust itself according to the product production quality requirement. Recarburizer is characteristic of carbon in liquid iron absorption effect is good, does not return slag, using recarburizer can reduce the cost of castings production.

Recarburizer features:

1, high fixed carbon, high absorption rate, low sulfur, low nitrogen, and on the absorption rate faster than similar graphitization carburant, and adsorption of furnace wall, fully absorbed no residue, price is lower than the similar sulfur is lower than 0.05 following the graphitization of carburant, the highest cost performance.

2 absorption rate is high, according to the method using the highest absorption rate can reach more than 90%.

3 absorption speed, than the similar graphitization recarburizer fast absorption and adsorption of furnace wall, and no residual, furnace increases in carbon absorption speed advantage is more obvious.

Low sulfur, 4 below 0.05%, the lowest 0.02%. N a low, 100 parts per million

5 ultra high performance to price ratio, review the above to the same type of graphitization recarburizer sulfur (0.05) or less price is most advantage.

Recarburizer method of use:

1. 5 tons of electric furnace, scattered recommend joining method. According to carbon content requirements according to ingredients than the carburant and metal furnace charge to join electric furnace bottom part with other ingredients.

(2). Use 2-3 tons of intermediate frequency induction furnace, the recommended concentration to join method: in hot melt furnace part or a small amount of hot metal, the remaining will need with addition of recarburizer one-time to add in the hot metal surface, and add metal furnace charge immediately, to press the carburant all into molten iron, carburant and good contact with the molten iron.

(3). Using a small intermediate frequency electric furnace, such as material single stability, recommend add recarburizer concentrated at the bottom of the furnace; Raw materials with high carbon material of cast iron, the recommended recarburizer fine-tuning: adjusting carbon after the steel or hot metal melting, can be added to steel or iron on the surface, through melting molten iron of the vortex stirring to dissolve the product absorption.

High quality recarburizer with features

1. Particle size, porosity, absorption speed.

2. The chemical composition of pure, high carbon, low sulfur, extremely harmful ingredients, high absorption rate.

3. Good products graphite crystal structure, improve the capability in the shape of liquid iron. Increased in the inoculation of nodular cast iron ball ink quantity, increase in the electric furnace iron graphite crystal nucleus. Refine the fossils, uniform ink distribution in the castings.

4. Excellent performance, stable. Choose appropriate recarburizer helps reduce smelting production cost, improve the quality of metal smelting and casting.

Recarburizer specifications:

1-0.5-1 2 2-4 of 4-6 of 6-8 8-10 1-3 of 3-5 of 5-8 mm and so on the many kinds of specifications, can adjust the production according to customer's request.

Recarburizer packing:

25 kg/bag, double braided packing, also can use tons of bags, specific packaging requirements can be adjusted according to customer requirements production.

實拍圖片:

聯系方式:

公司名稱:寧夏明陽活性炭有限公司

地址:平羅縣太沙工業園區

銷售經理:劉雅

手機:15825325308

座機: 0952-5862158

傳真:0952-5862158

QQ :1654292989

網址:http://nxmyhxt.cn.alibaba.com/

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。