USMY-80N25S USMY-150N25S

超音波加工拋光機

Ultrasonic Processing Polishing Machine

一 概述

超音波加工拋光專用機是用來加工天然鉆石拉絲模和人造鉆石拉絲模的專用機器。具有加工效率高,質量好和噪音低的優點。能快速地對模具進行整形或拋光,並能快速地使加工麵達到鏡麵。

A. Introduction

Ultrasonic processing polishing machine is dedicated to processing natural diamond dies and man-made diamond dies. Have advantages of high efficient processing, good quality and low noise. It can reshaping dies or polishing quickly, and make processing side achieve mirror fast.

二 技術參數

型號 | USMY-80N25S | USMY-150N25S |

加工范圍(mm) | 0.01-0.40 | 0.05-4.00 |

電源 | 220V 50HZ | 220V 50HZ |

最大輸出功率(W) | 80 | 150 |

換能器 | 日式電感式 | 日式電感式 |

工作頻率(KHZ) | 25 | 25 |

模座轉速(rpm/min) | 130 | 130 |

模座搖擺(time/min) |

| 30 |

搖擺角度 |

| 不小於12度(可調) |

加工方式 | 液壓傳動 砝碼加壓 或可調式磁懸浮任選 | 液壓傳動 砝碼加壓 或可調式磁懸浮任選 |

B. Technical Parameter

Model | USMY-80N25S | USMY-150N25S |

Processing range(mm) | 0.01-0.40 | 0.05-4.00 |

Power source | 220V 50HZ | 220V 50HZ |

Max output power(W) | 80 | 150 |

Transducer | Japanese inductive | Japanese inductive |

Working frequency(KHZ) | 25 | 25 |

Mould base rotating speed(rpm/min) | 130 | 130 |

Mould base swing(time/min) |

| 30 |

Swing angle |

| Above 12 degree(adjustable) |

Processing way | Hydraulic pressure transmission, weight increased, or adjustable magnetic levitation for your choice | Hydraulic pressure transmission, weight increased, or adjustable magnetic levitation for your choice |

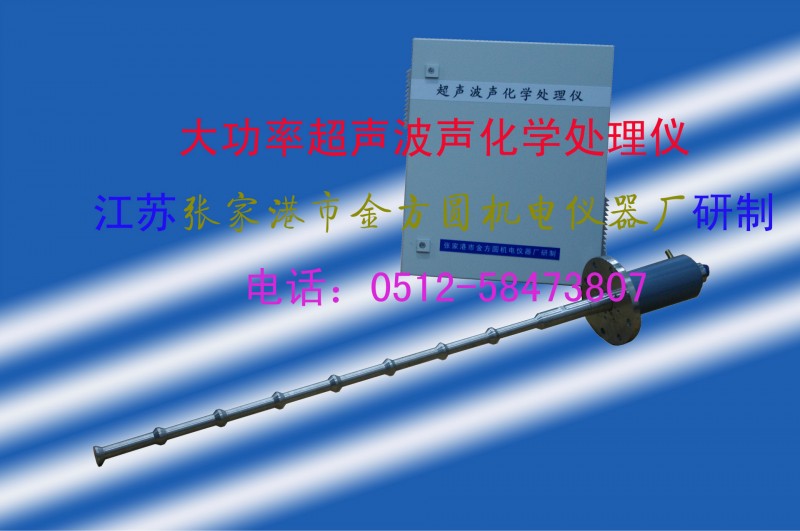

三 工作原理及設備構成

本機是利用超音波高速震蕩,通過鋼針及磨料,在被加工麵上產生撞擊,磨削被加工麵,使之達到需要的形狀及尺寸。本設備主要由超音波發生器、換能器、機座三部分組成。

(1)超音波發生器: 超音波發生器被安裝在一個450*210*410*的鐵皮箱子內,為一個超音波電源。線路采用頻率自動跟蹤,對不同的鋼針能自動修正頻率,使之相匹配,從而達到超聲輸出及震蕩效果。

(2)換能器: 換能器為高效磁致伸縮水冷式。具有高效的換能效果,能將超音波轉換成平穩地超聲震蕩,冷卻采用加水循環冷卻,並具有噪音小之特點。

(3)機座:工作臺可旋轉,使工作件加工後能確保真圓度的機座,被安裝在一個十字拖板上,並通過液壓傳送,砝碼加壓,靈活地上下移動,在皮帶輪帶動下可以旋轉,而十字拖板又可以自由地對中心,以達到真圓的目的。後立柱上有一副可以升降移動的拖板,換能器就安裝在這一拖板上。

C.The principle and equipment constitution

The machine is to use ultrasonic high-speed vibration through draw point and grinding compound impacting on the processing surface to grind machined surface, then meet the required needs of shape and size. Equipment consists of three parts: ultrasonic generator, transducer, machine base.

1)Ultrasonic generator: ultrasonic generator was installed in a 450 * 210 * 410 * iron box, a power ultrasound. Line adopt frequency automatic tracking, can automatically correct frequency for various draw point to make it match, so as to achieve output of ultrasound and vibrating effect.

4、安裝及使用:

(1) 安裝:把機座放置在平穩的桌麵上,將換能器升降移動調整至合適的位置然後鎖緊,將超音波發生器及砂輪機放置在旁邊,然後用隨機所配的輸出線將超音波發生器與換能器連接起來,而將機座上的電源插頭插入超音波發生器的電源輸出插座上。打開油閥開關,提起活塞桿,使油進入管道,然後關上油閥開關,放下活塞桿,將砝碼放置在活塞桿上。檢查無誤後,在開關都處於關的狀態下將超音波發生器電源插頭插入帶有牢固接地線的電源插座上。

(2)使用: 根據所需加工模具的大小,選擇合適的變幅桿和鋼針,將鋼針用銀焊條牢固地焊接在變幅桿上。然後在砂輪上磨削出合適的角度,裝在換能器上擰緊。模具放在模座上,調節十字脫板及換能器上下拖板,使鋼針插入模孔內,調整砝碼壓力,然後放上磨料,打開超音波電源開關和模座旋轉開關。調節超音波輸出功率旋鈕至適當大小,然後可見磨料在超音波作用下攪動,即模具加工或拋光正在進行中。

4. installation and usage:

(1) installation: Put the machine base on stable desktop, move transducer to adjust to an appropriate location and then lock, place ultrasonic generator and wheel machine next to it, and then connect Ultrasonic generator and transducer by assigned output line, and insert power plug of machine base into power output socket of ultrasonic generator. Open the oil valve switch, bring piston rod so that the oil into the pipeline, then close oil valve switch and lay down piston rod and place the weight on the piston rod. After check,insert power plug of ultrasonic generator into power socket with a solid grounding line when the switch are in the close condition.

(2). In accordance with size of processing die, choose the right horn and steel needle, welding steel needle into the horn by silver welding rod firmly. Then grind a suitaleangleon the wheel, then install into the transducer and tighten. Put die on the die seat, adjust cross- plate and transducer draging plate of up and down, so that the steel needle can be inserted into die hole to adjust the pressure of weight, and then place the abrasive, open power switch of ultrasonic and rotating switch of die seat. Adjust ultrasonic output power knob to the appropriate size, and can see abrasive stirring in ultrasonic function, that is, die process or polishing is in progress.

批發市場僅提供代購諮詢服務,商品內容為廠商自行維護,若有發現不實、不合適或不正確內容,再請告知我們,查實即會請廠商修改或立即下架,謝謝。